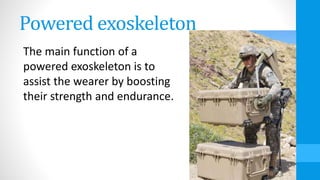

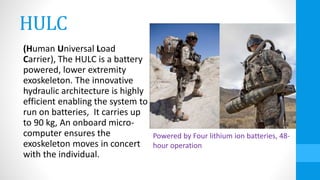

An exoskeleton is a powered external framework that attaches to a person to boost their strength and endurance. While early attempts in 1965 were unsuccessful, current exoskeletons use hydraulics or electric motors to help lift heavy loads. They are used militarily but also have applications in industries like construction, healthcare for moving patients, and rehabilitation. Technological challenges include developing lightweight yet powerful actuators, joint flexibility, and precise computer controls to move in sync with the wearer.