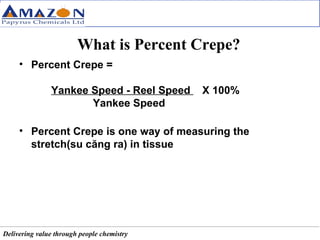

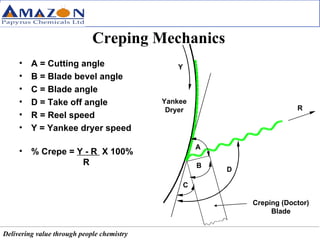

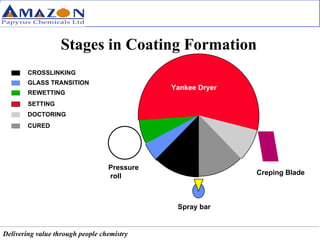

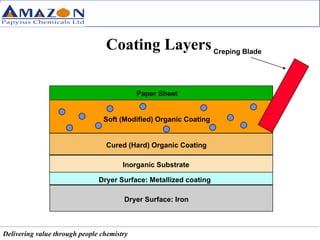

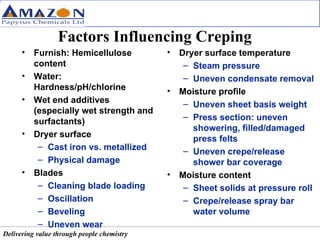

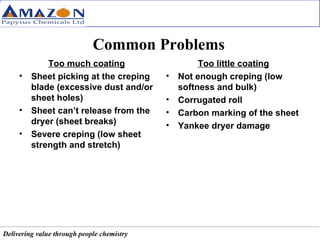

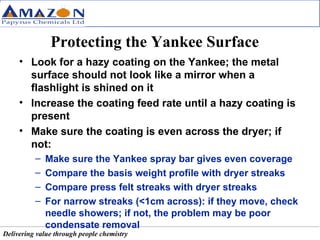

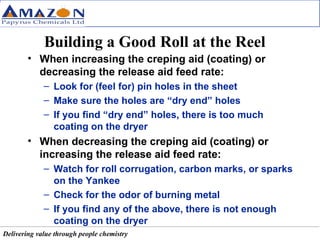

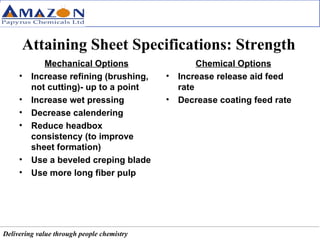

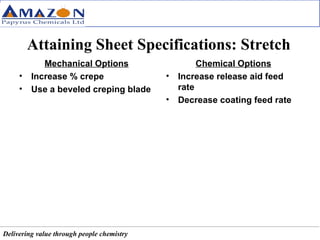

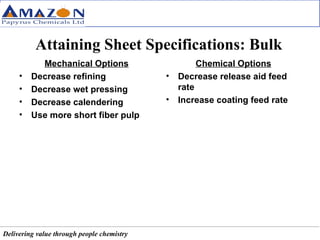

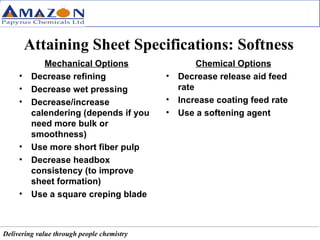

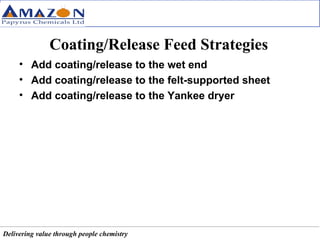

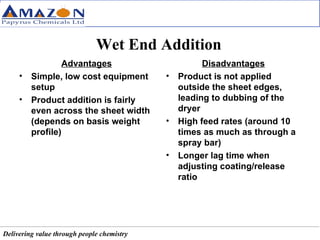

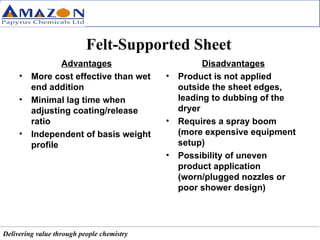

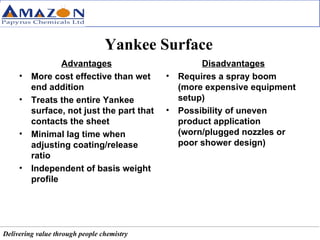

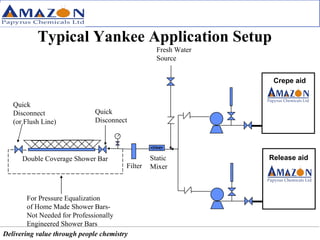

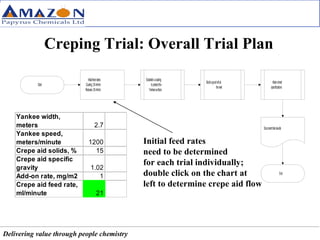

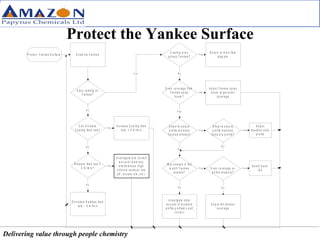

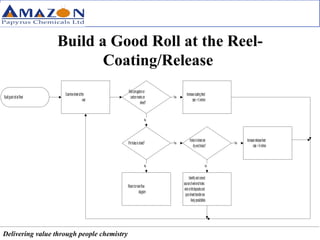

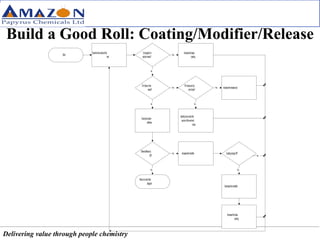

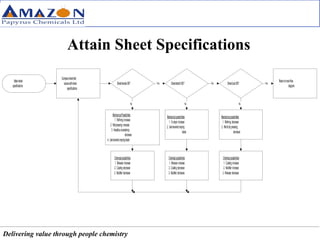

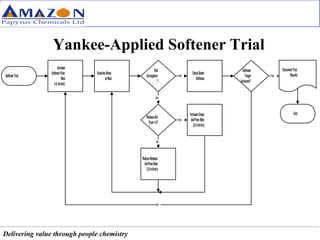

The document provides an overview of tissue machine operator training, focusing on crepe tissue production and the factors that influence creping. It discusses how increasing percent crepe through differences in yankee and reel speeds can improve sheet properties like bulk and softness. It also explains that coatings are applied to the yankee dryer to hold the sheet during creping and help build a good roll, while release aids facilitate sheet removal and influence properties. Common problems and methods for adjusting crepe, coatings and release aids to protect the dryer surface and meet sheet specifications are described.