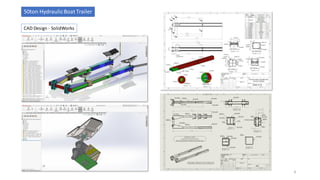

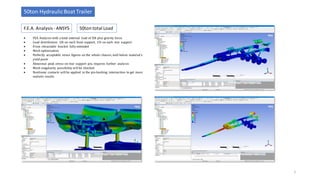

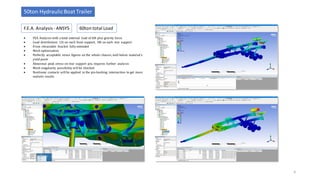

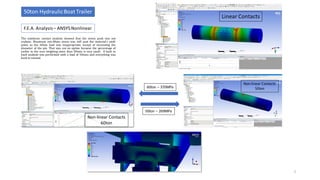

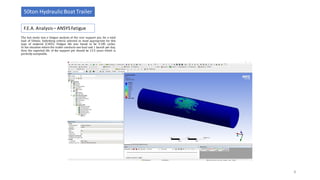

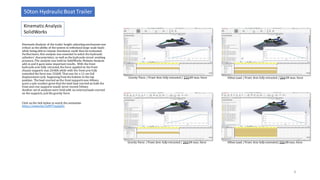

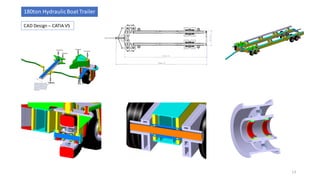

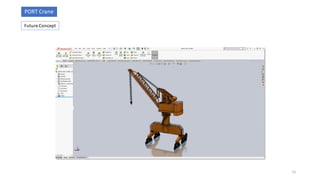

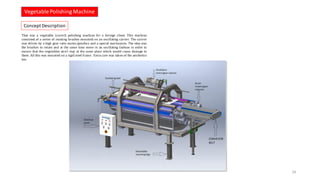

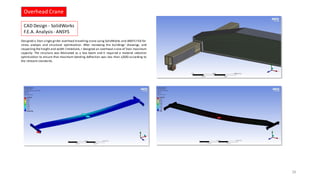

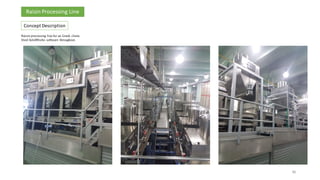

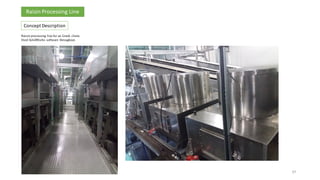

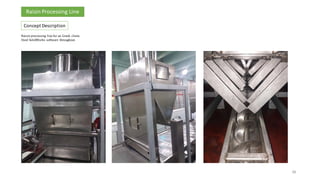

The document contains a portfolio for Theodoros Dragonas, a mechanical design engineer with experience in various industries including marine, construction, special purpose machinery, food processing, and motorsports. It includes descriptions and images of projects such as boat trailers up to 200 tons, ship components, factory machinery, and a prototype racing car. The portfolio highlights Dragonas' skills in mechanical design, analysis, and project management for customized engineering solutions.