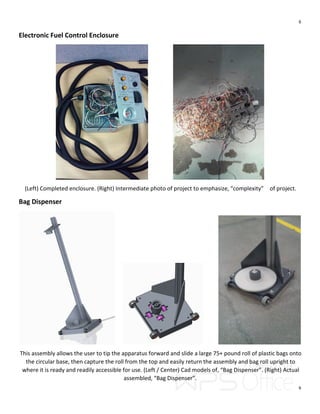

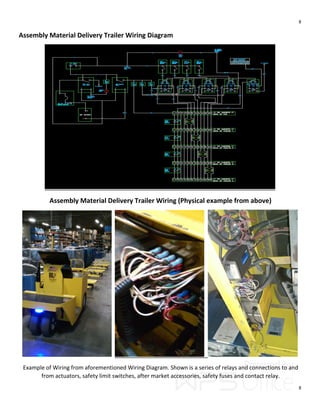

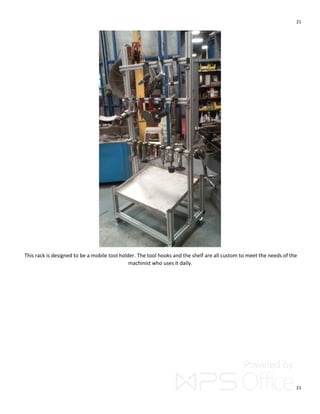

This document contains a summary of engineering projects from the University of Colorado and Kärcher North America. It includes projects such as an organic Rankine cycle turbine and housing, a drill torque differentiator, various electrical test fixtures, an electronic fuel control enclosure, a bag dispenser, actuator controls, a machine test fixture cart, a material delivery system, zip-tie dispensers, assembly holders, 3D printed non-circular gears, a 3D printed band brake system, a safety fence, and a traveling air tool holding rack.