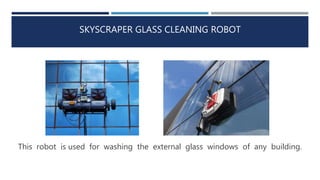

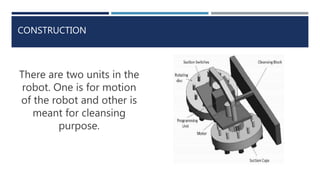

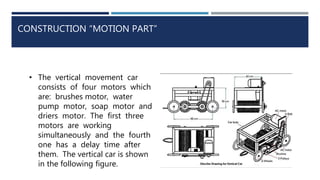

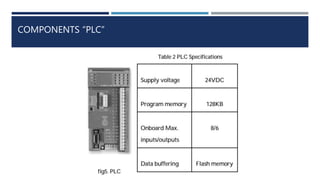

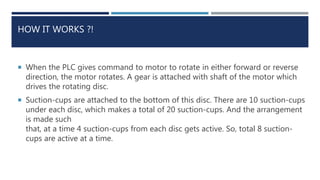

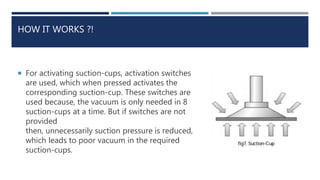

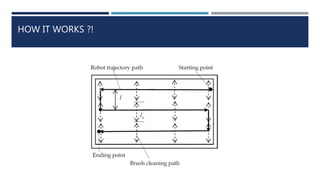

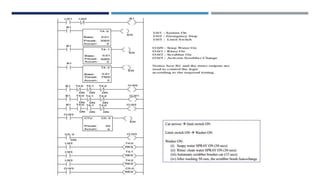

This document summarizes a PLC project for a skyscraper glass cleaning robot. The robot uses suction cups to climb glass surfaces of high-rise buildings and clean the glass. It has two units, one for motion and one for cleaning. The motion unit uses motors to provide horizontal and vertical movement. The cleaning unit uses rotating cylinders, one with brushes and one with sponges, to remove dust and dirt from the glass along with a wiper. A PLC controls the motors and cleaning components to automate the glass cleaning process.