Embed presentation

Download to read offline

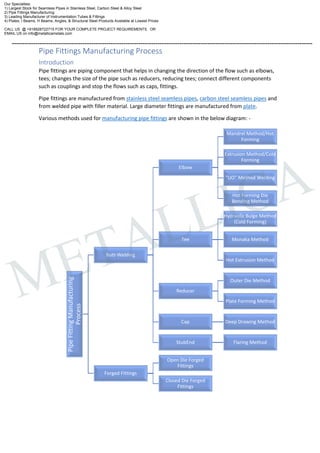

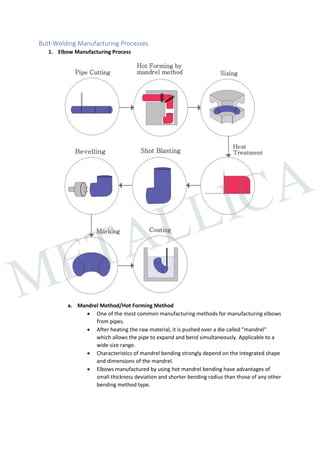

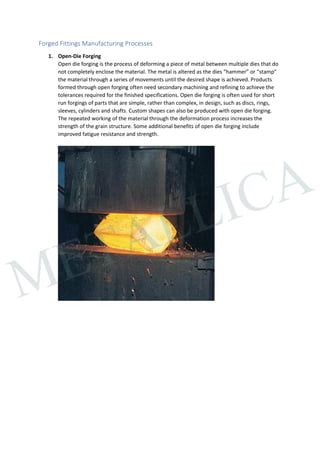

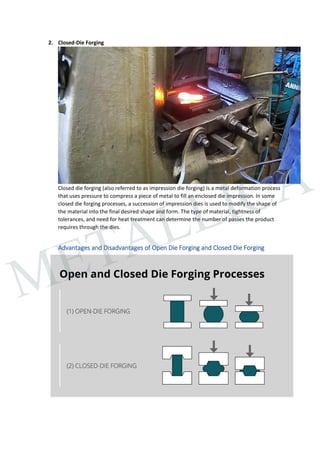

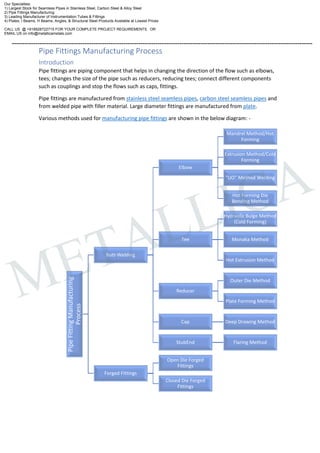

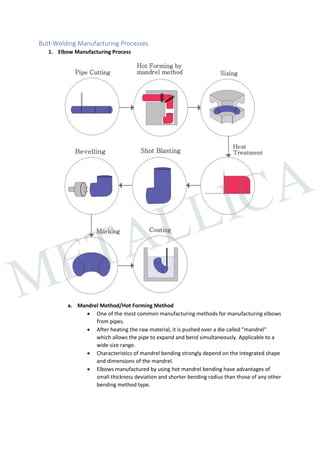

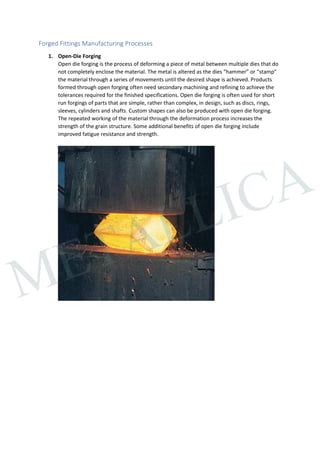

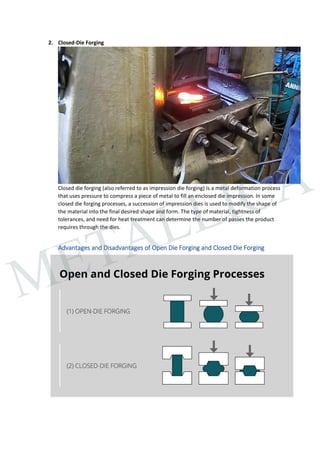

The document outlines the manufacturing processes of various pipe fittings, including elbows, tees, reducers, caps, and forged fittings, detailing methods like mandrel bending, extrusion, and hot forming. It emphasizes Metallica's capabilities in producing high-quality fittings from seamless and welded pipes, highlighting their expertise in various material grades and manufacturing techniques. Additionally, the document lists the types of fittings produced and invites potential customers to inquire for prices and details.