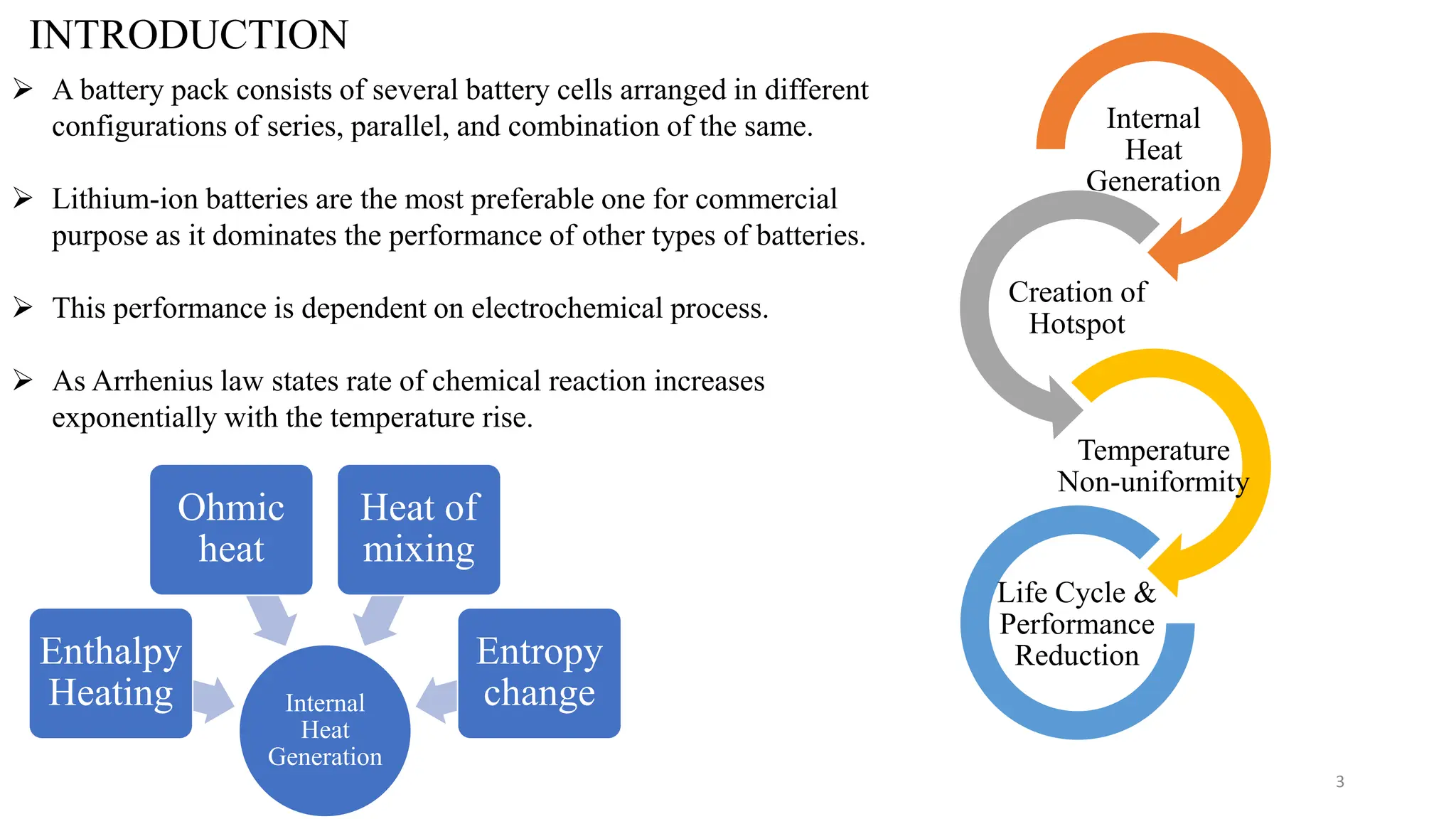

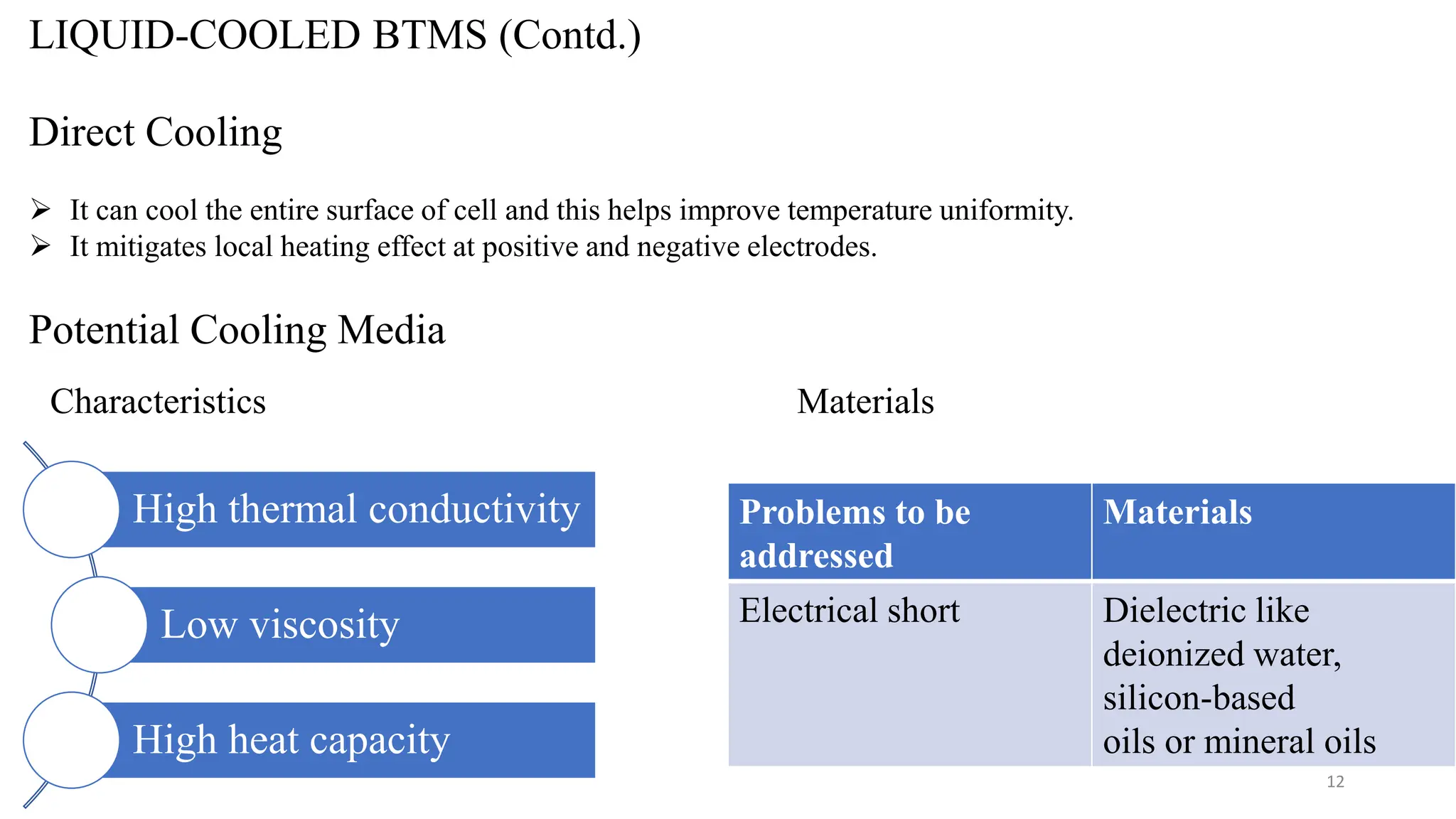

The presentation discusses developments in battery thermal management systems for electric vehicles. It begins with an overview of various EV components including battery technology and focuses on battery thermal management systems. Various battery thermal management system types are described including air-cooled, liquid-cooled, PCM-based, and hybrid systems. Specific designs and mechanisms within each type are also summarized. The effects of temperature on battery performance and methods to maintain optimal operating temperatures are highlighted.