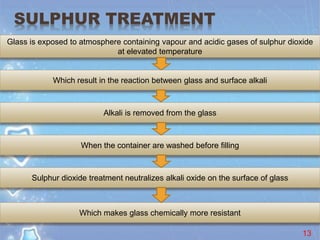

This document discusses pharmaceutical packaging. It defines pharmaceutical packaging and describes the primary and secondary/tertiary packaging systems. The key requirements for pharmaceutical packaging are to protect the product, be non-reactive, prevent contamination, and be FDA approved. Important criteria for selecting packaging materials include stability, compatibility with contents, strength, moisture protection, and cost. Common packaging materials include glass, plastic, metal, paper, rubber, and closures. Guidelines for quality control of packaging materials require containers and closures to meet pharmacopeial standards and be properly washed and sterilized.