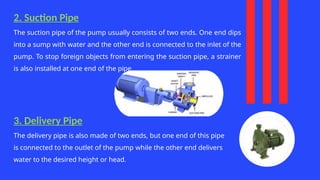

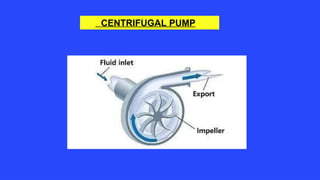

The document provides a comprehensive overview of centrifugal pumps, detailing their components, working principles, classifications, and performance characteristics. It explains how centrifugal pumps convert mechanical energy into hydraulic energy through the action of impellers and casing. Additionally, it compares single-stage and multi-stage pumps, highlighting their advantages and applications in various industries.