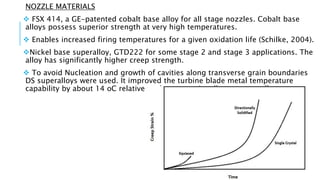

This document provides an overview of materials used in gas turbine components such as compressors, combustors, turbines, and nozzles. It discusses the challenges associated with each component and how material requirements have evolved over time. For compressors, titanium alloys are widely used due to their high strength to weight ratio, with Ti-6Al-4V being common. Superalloys are needed for the last compressor stages due to higher temperatures. Combustor materials require high temperature creep resistance and oxidation resistance, leading to the use of nickel and cobalt-based superalloys. Turbine disks were initially made of steel but now use nickel-based superalloys like alloy 718 for their high strength. Blades and van