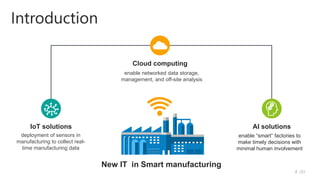

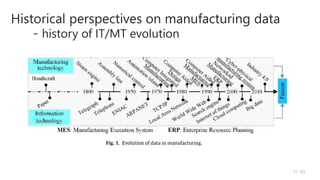

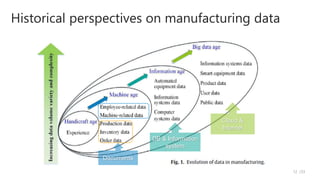

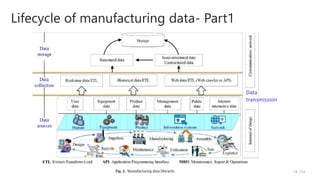

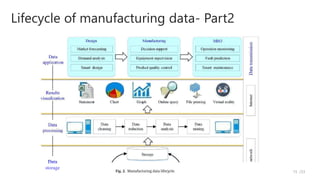

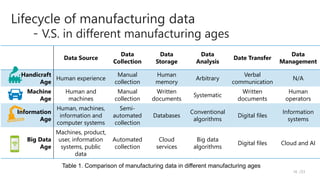

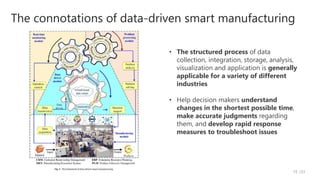

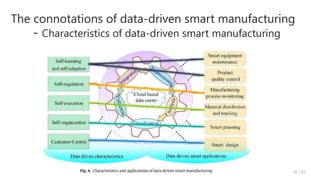

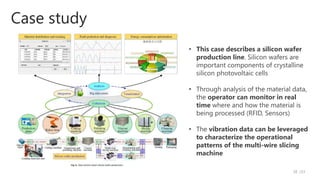

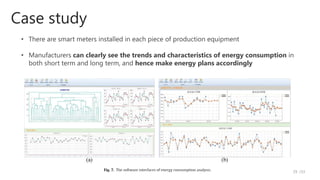

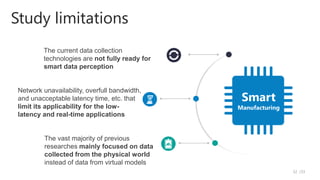

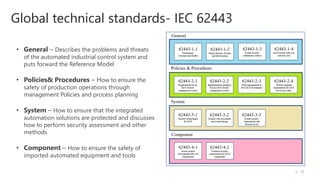

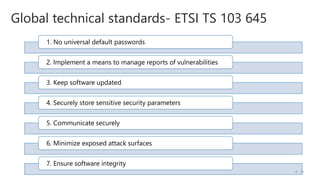

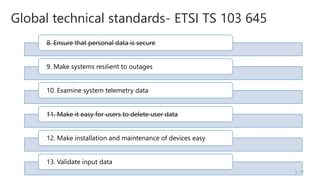

The document discusses the evolution and significance of data in smart manufacturing, highlighting the role of IoT, AI, and cloud computing in enhancing manufacturing processes. It outlines the data lifecycle in manufacturing, applications of data-driven strategies, and a case study on silicon wafer production, emphasizing real-time monitoring and quality control. Additionally, it addresses security challenges and global technical standards necessary for secure smart manufacturing systems.