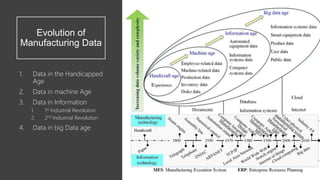

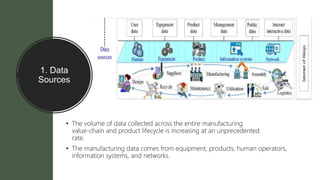

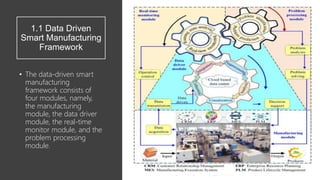

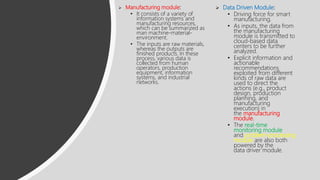

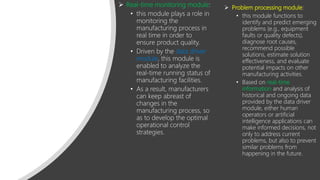

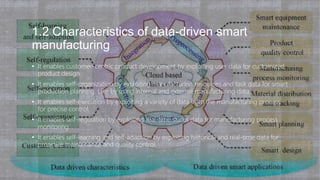

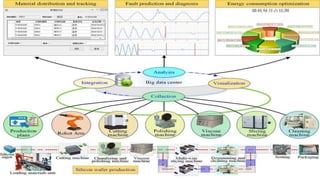

This document discusses the impact of advanced technologies on smart manufacturing, particularly highlighting the role of big data throughout the manufacturing data lifecycle. It outlines the process of transforming data collected from various sources into actionable intelligence to improve efficiency and quality in manufacturing operations. Additionally, it presents a framework for data-driven smart manufacturing, along with promising applications and areas for future development.