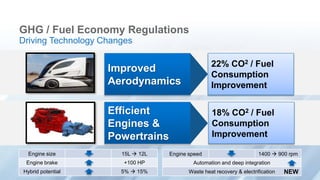

The document discusses Paul Menig's career leading technology development teams in various industries including medical equipment, aerospace, industrial automation, and trucking. It notes that he currently leads Future Truck efforts at Tech-I-M and is involved in activities regarding future fuel economy regulations and truck partnerships.

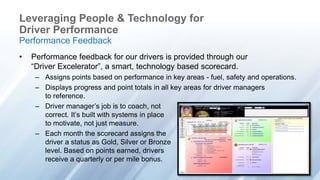

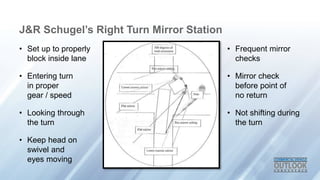

The next section discusses various technologies being used or considered for use in trucking, including driving simulators, onboard cameras, handheld devices, fleet management systems, collision mitigation radar, and automated transmissions.

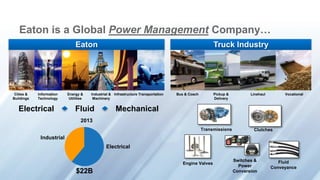

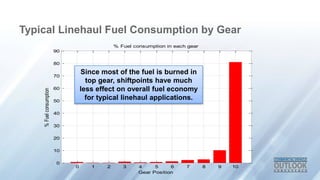

The final section introduces Gerard DeVito, who assumed responsibility for Eaton's global heavy duty automated transmission development. It notes his 28 years of experience at Eaton in various engineering, planning, strategy, and