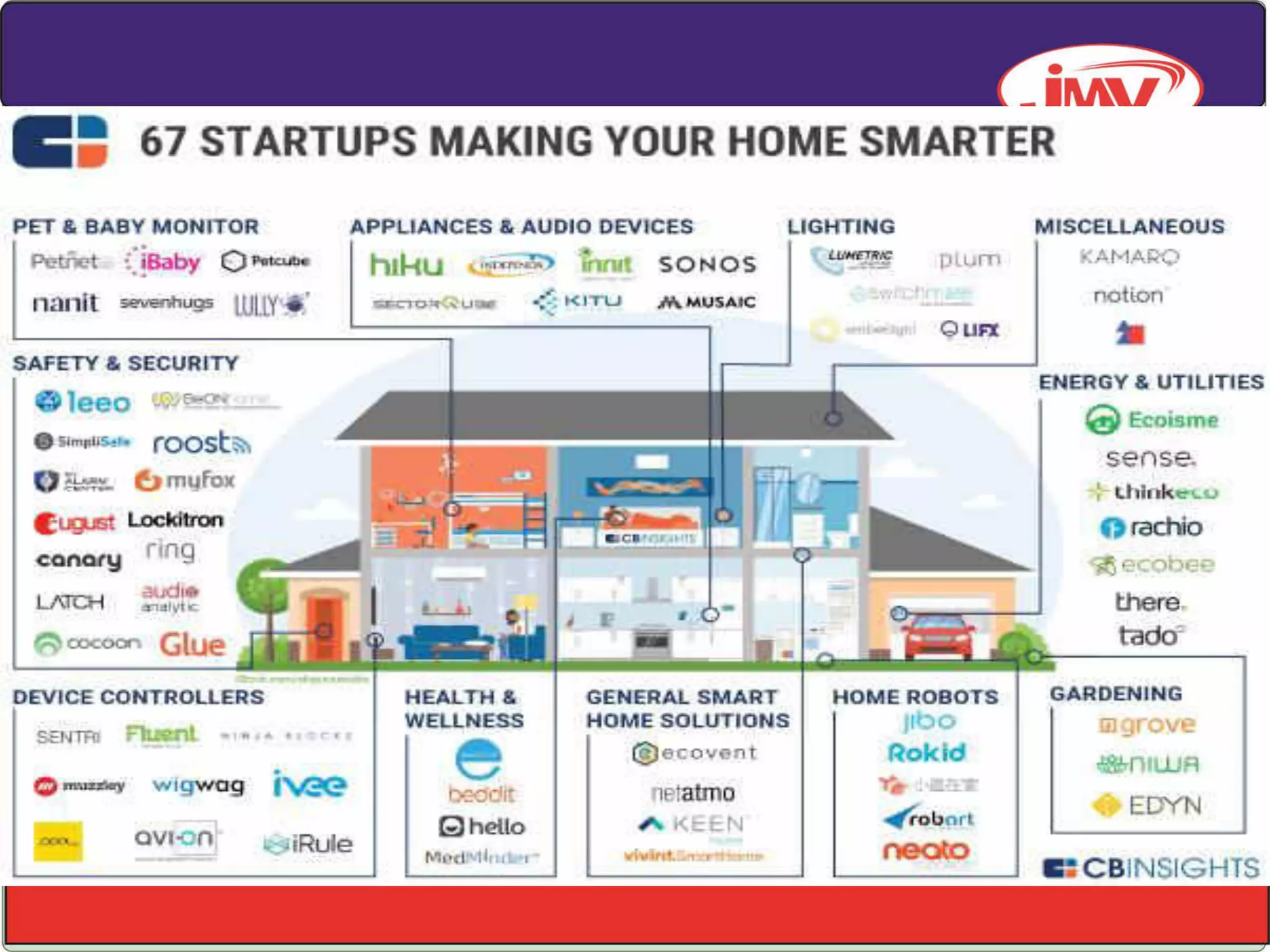

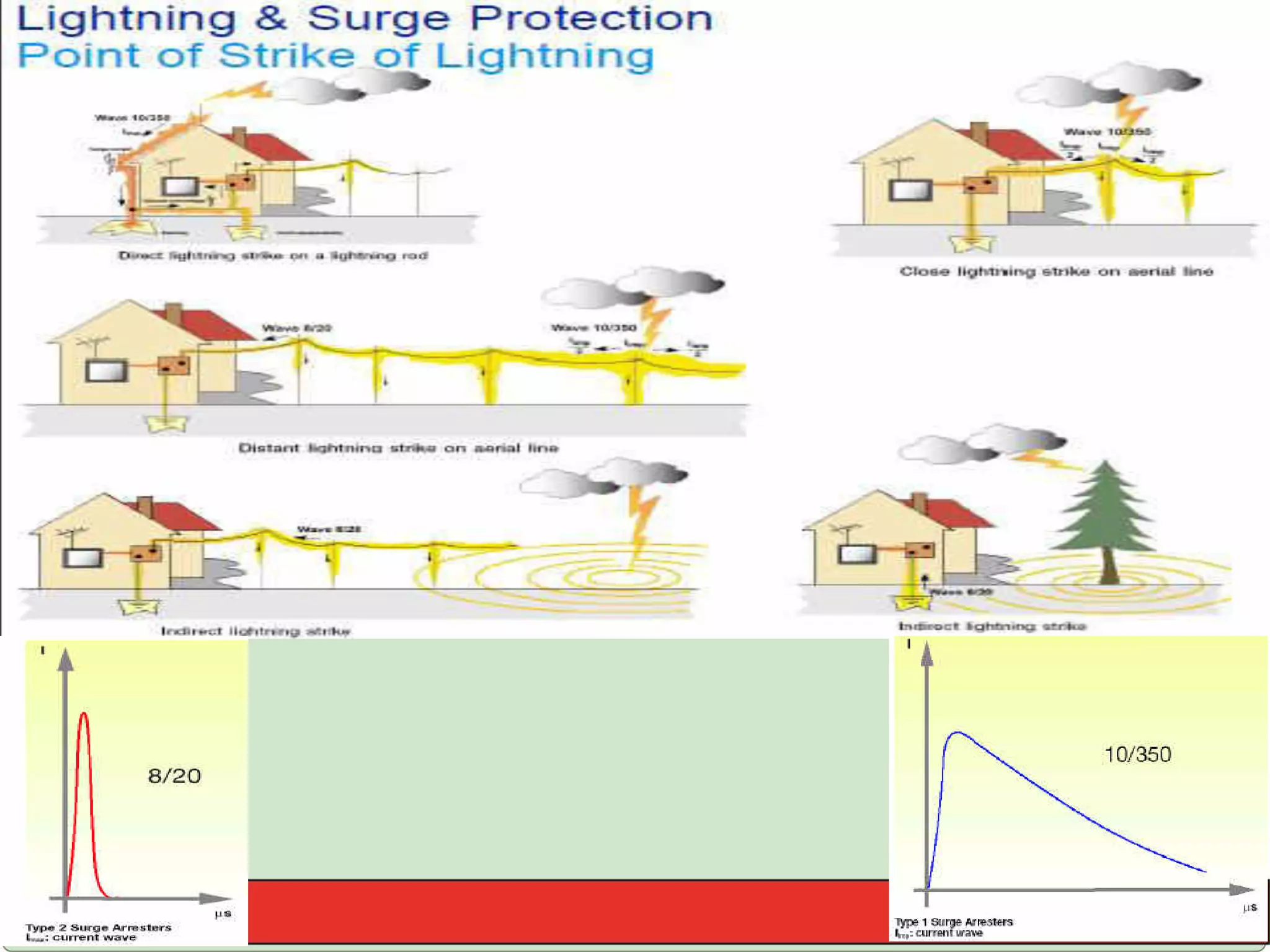

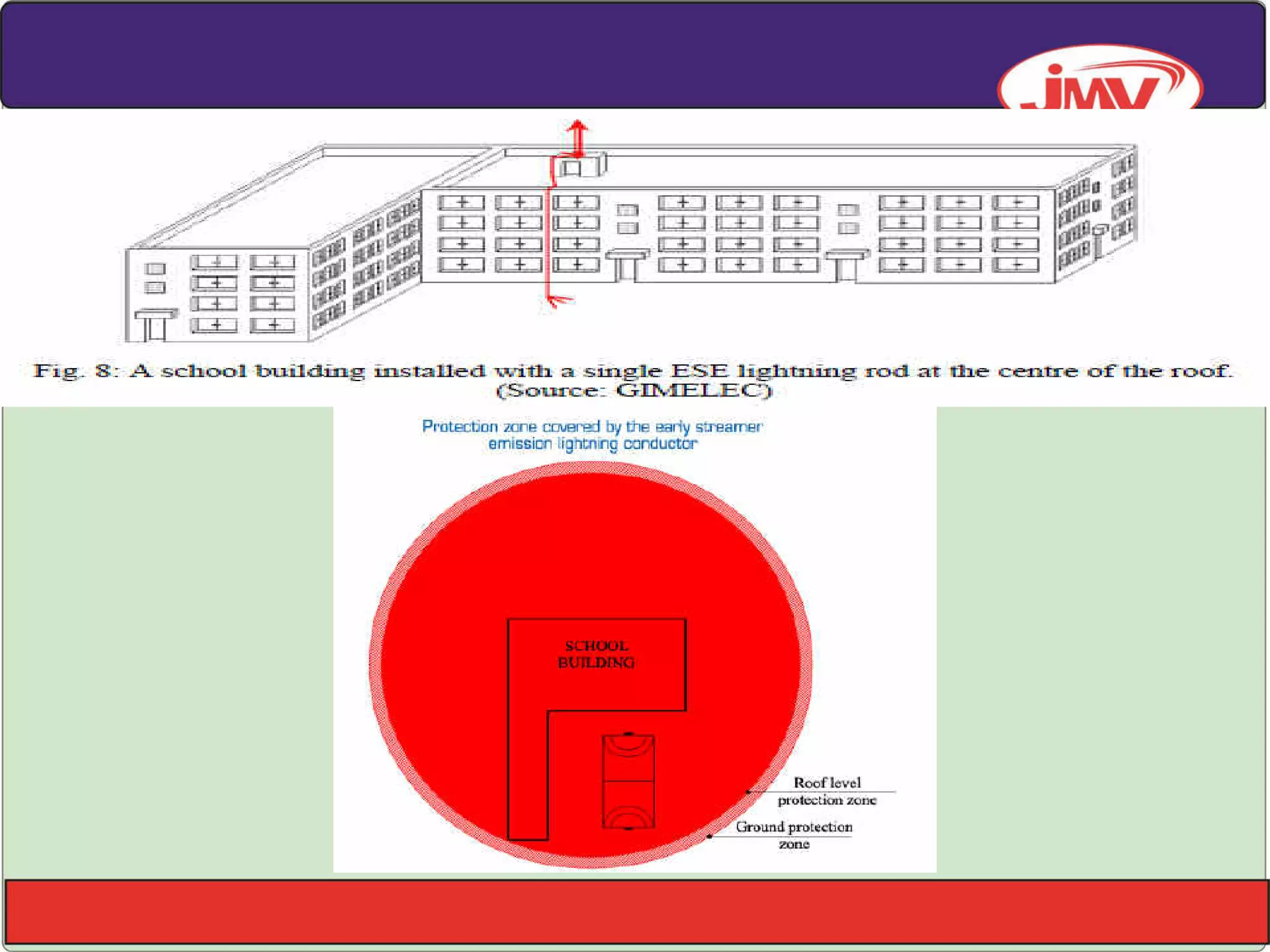

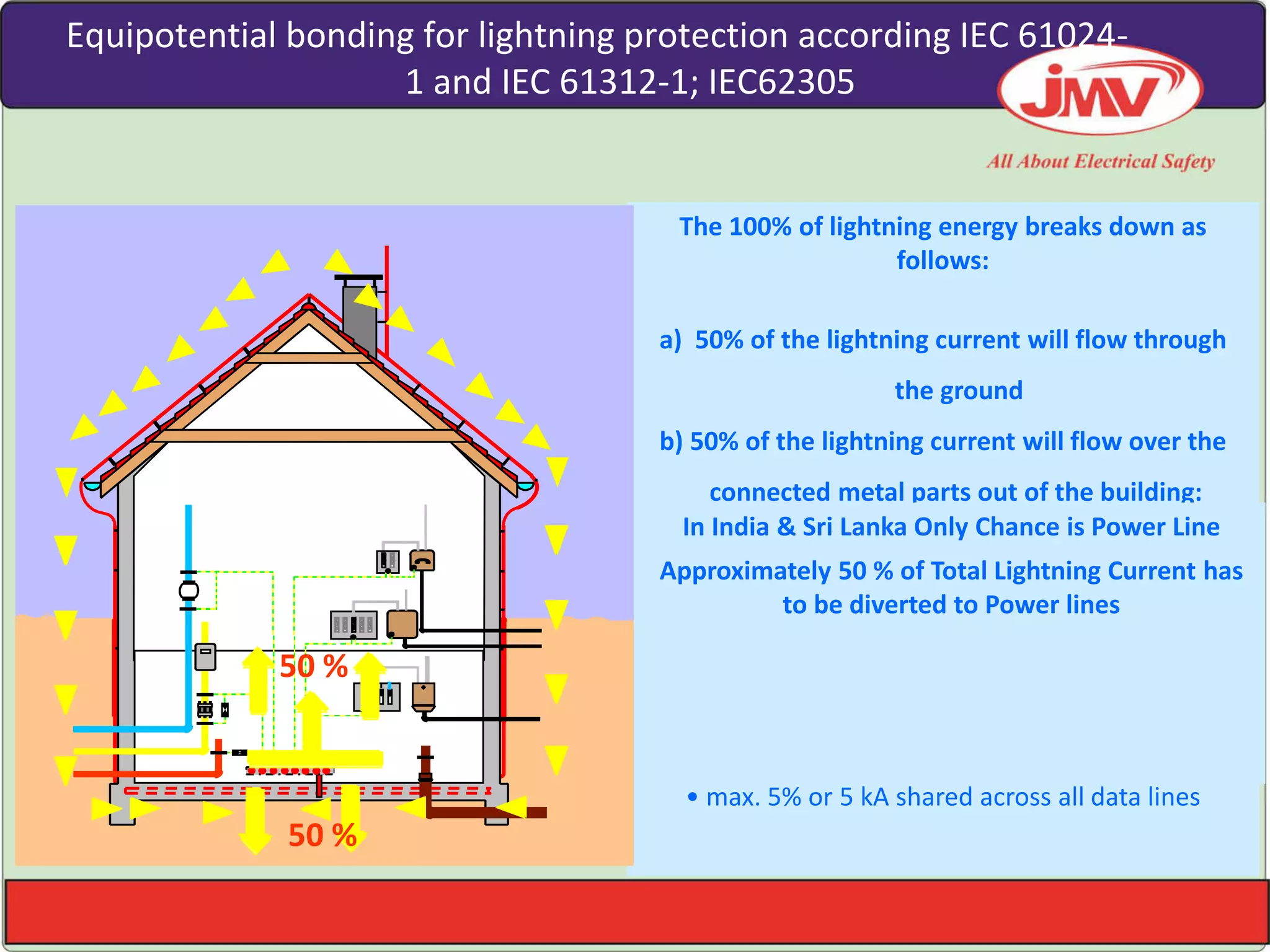

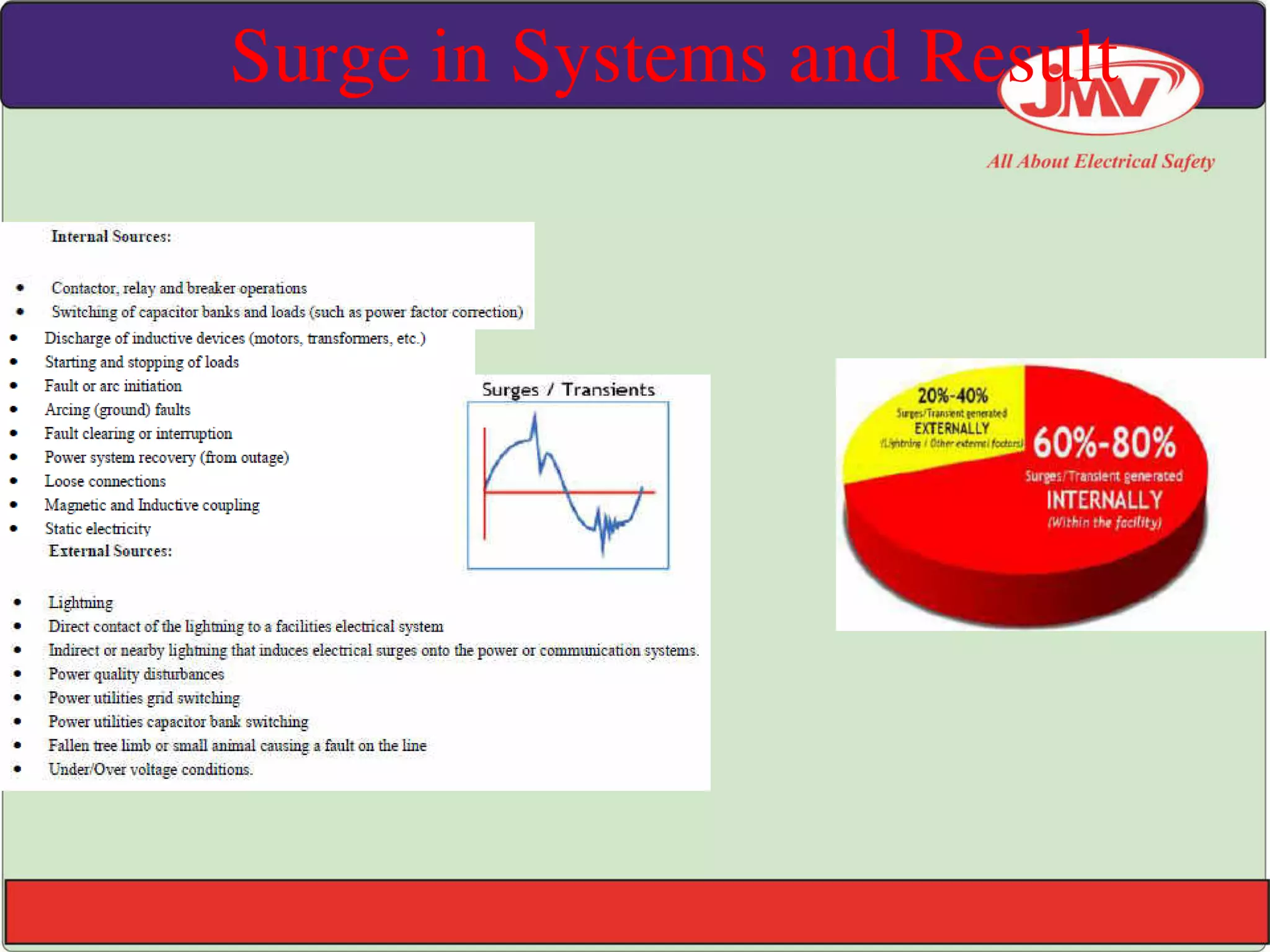

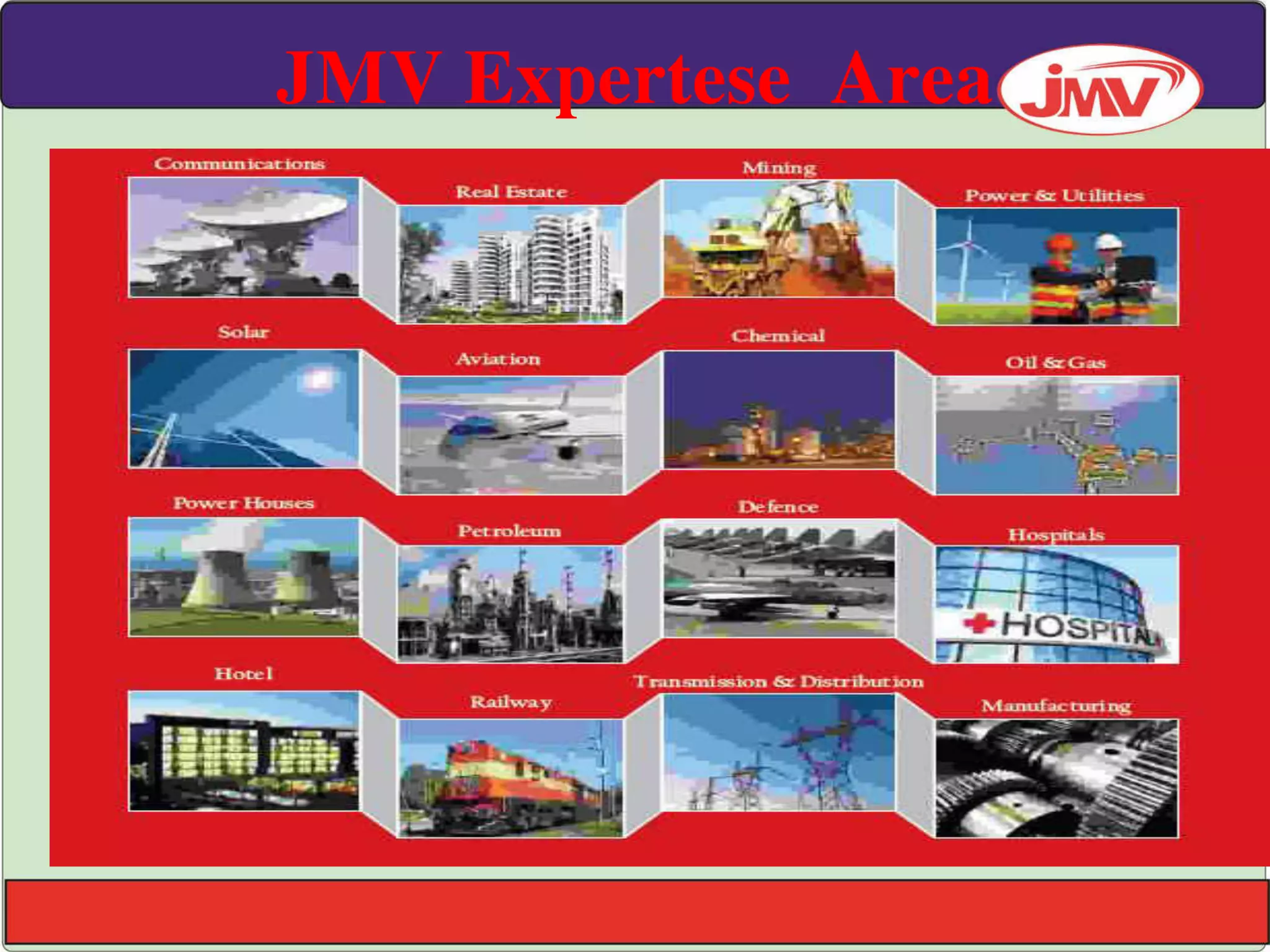

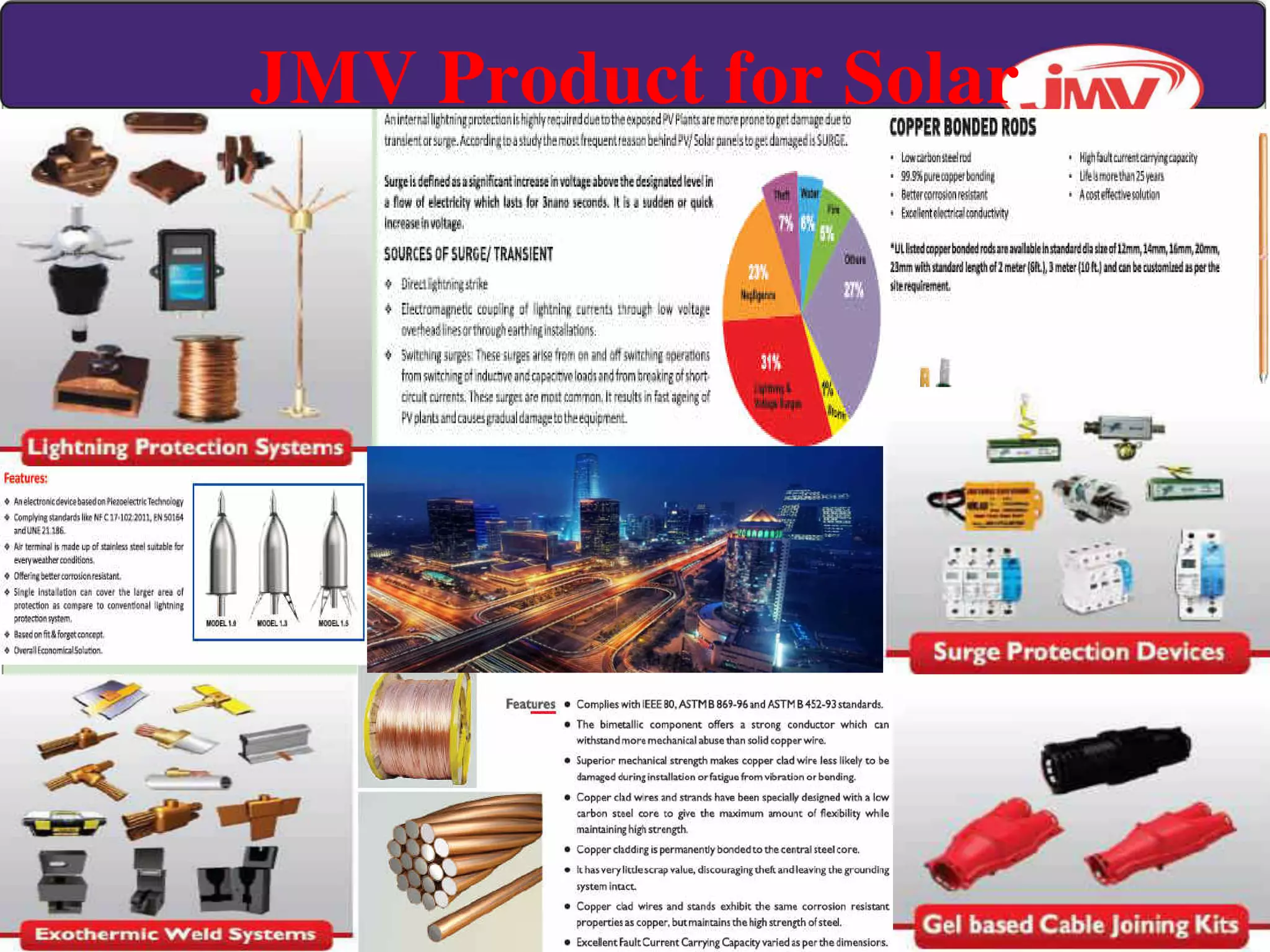

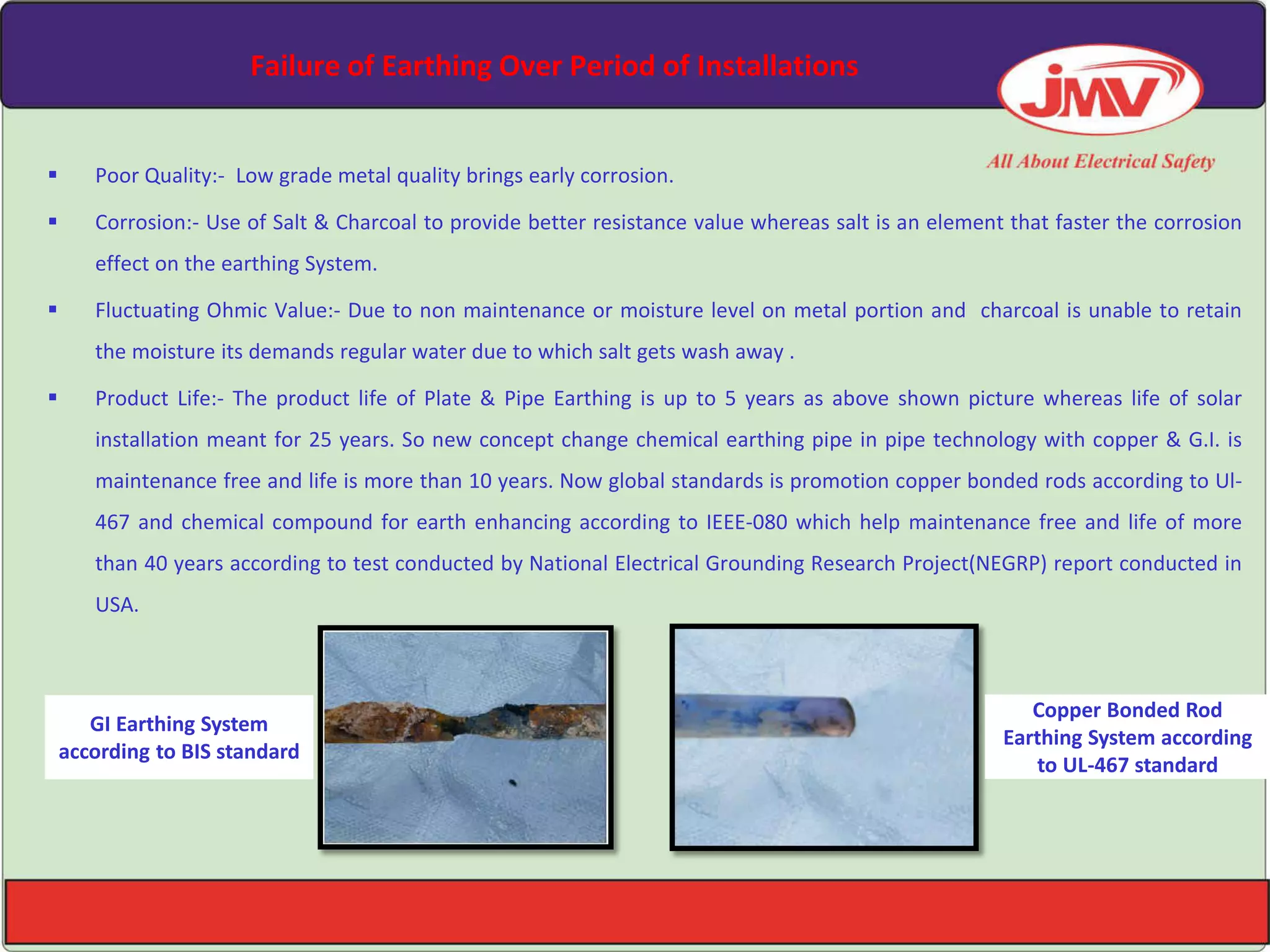

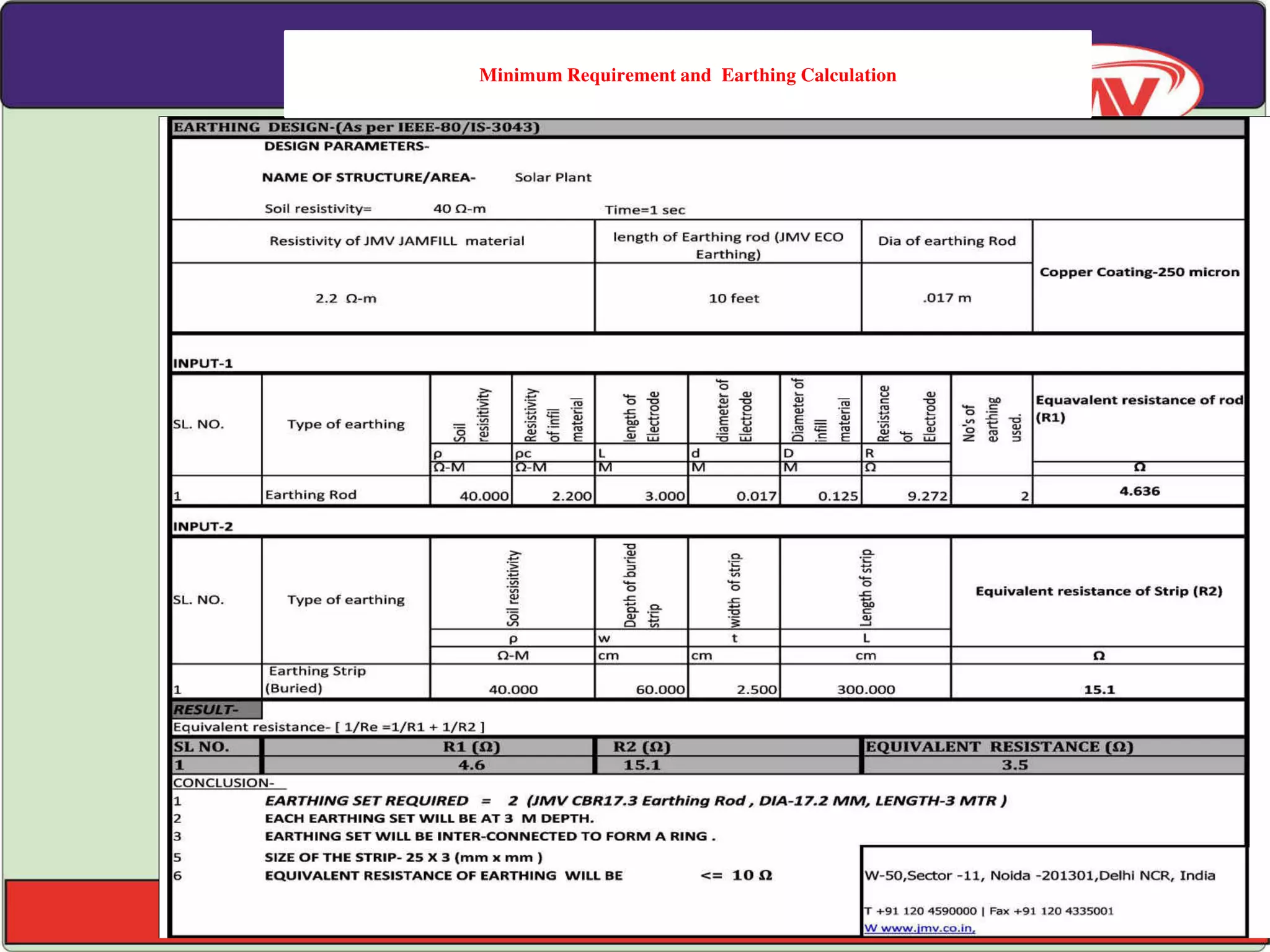

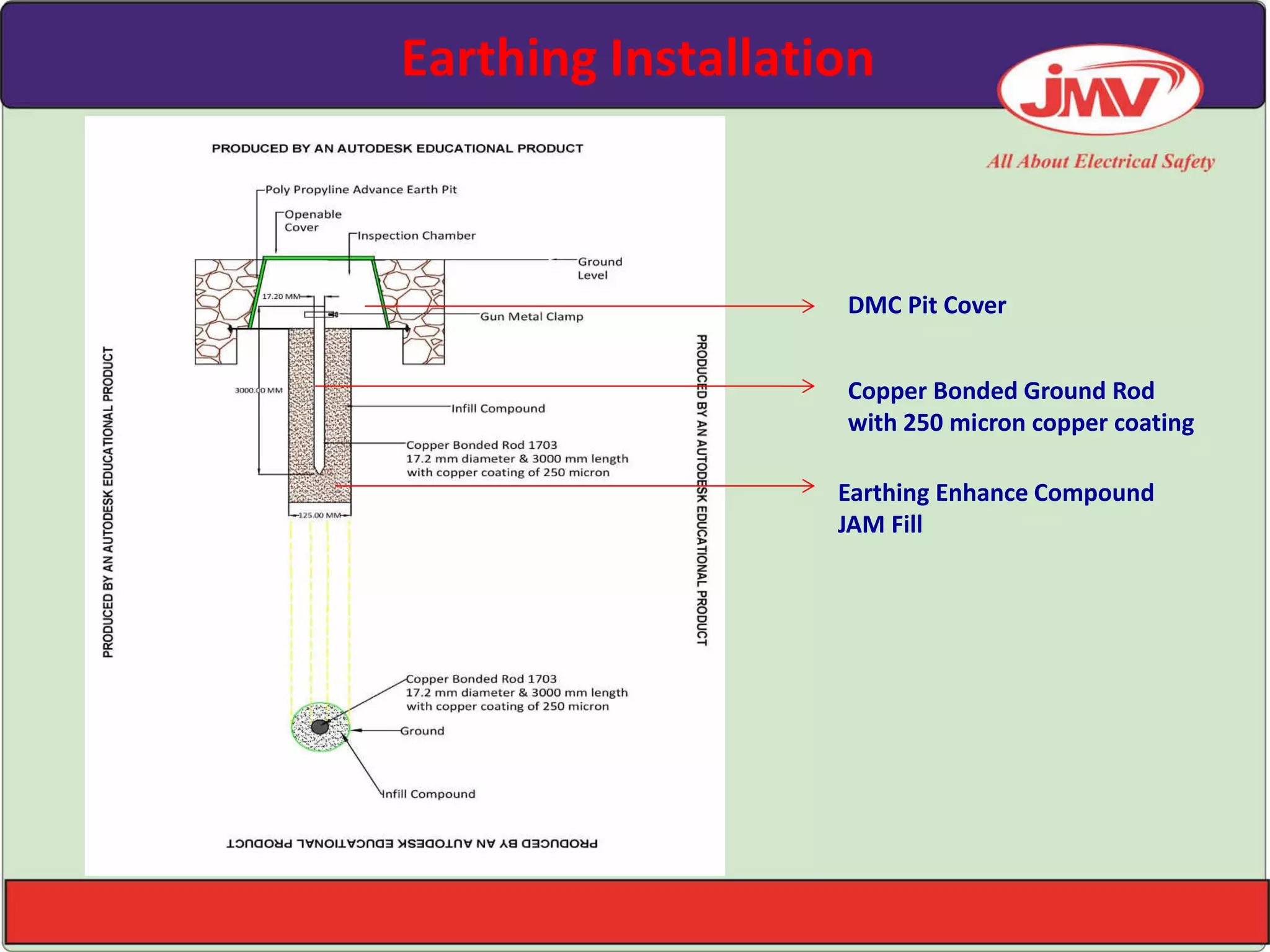

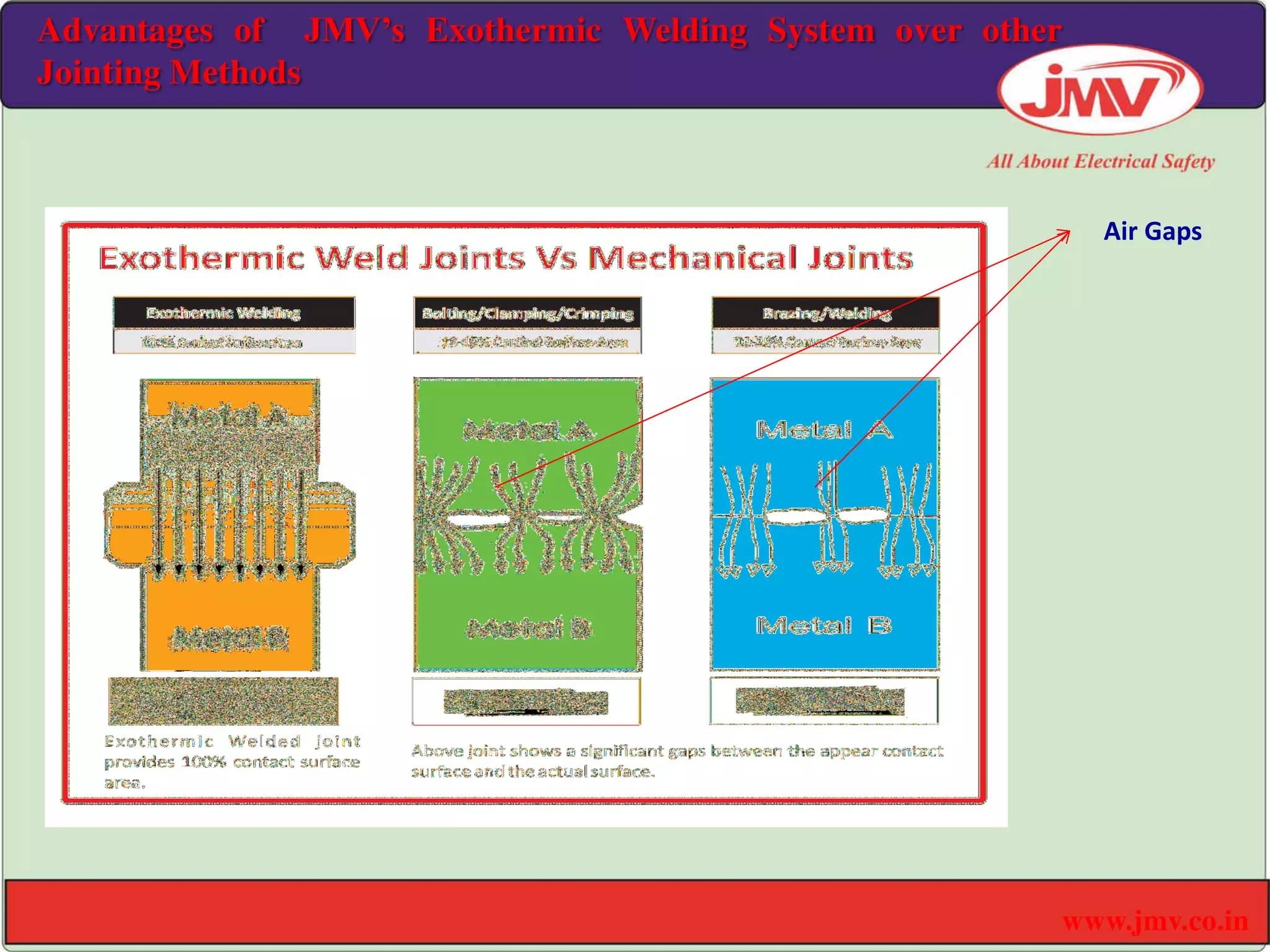

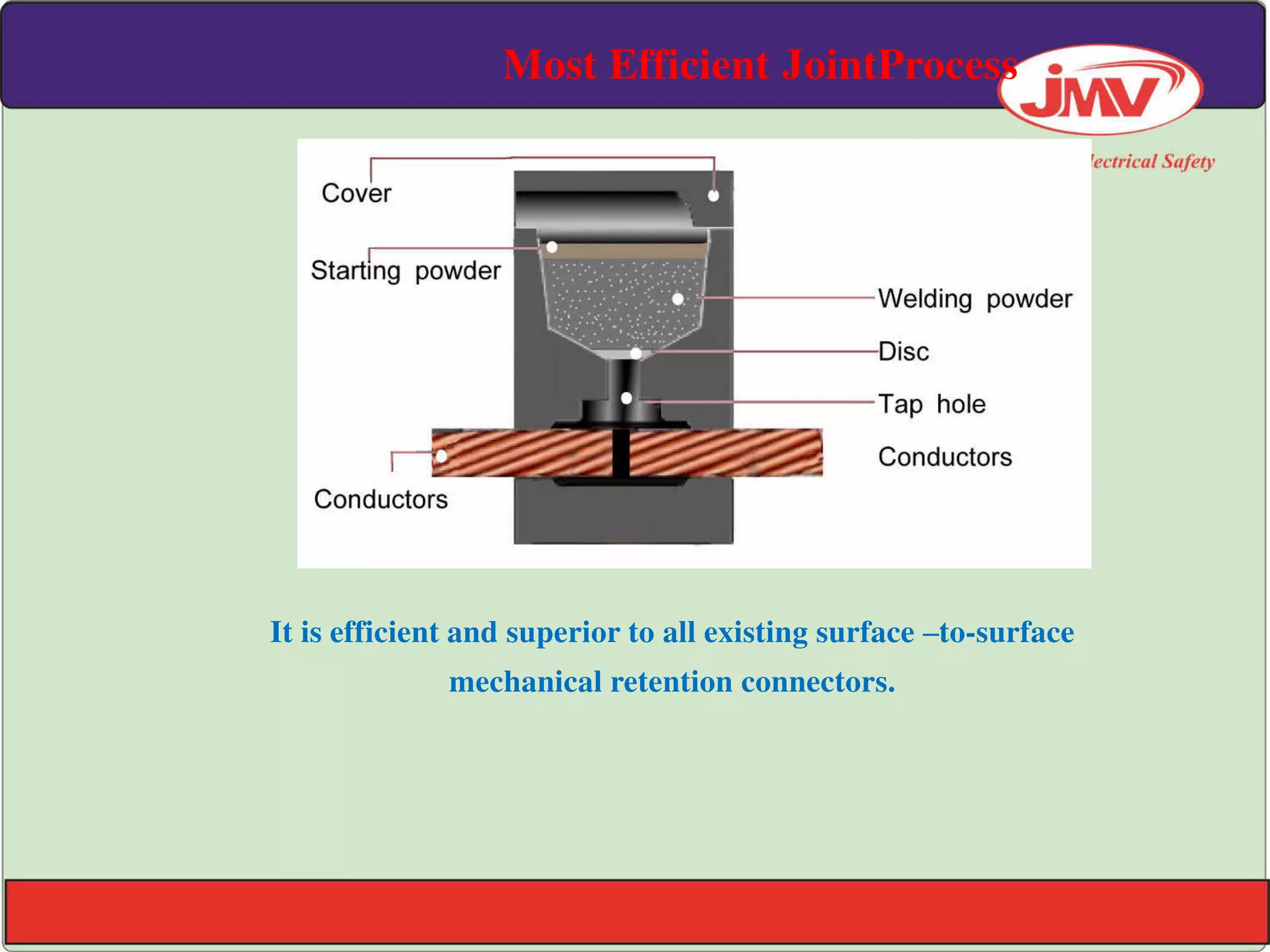

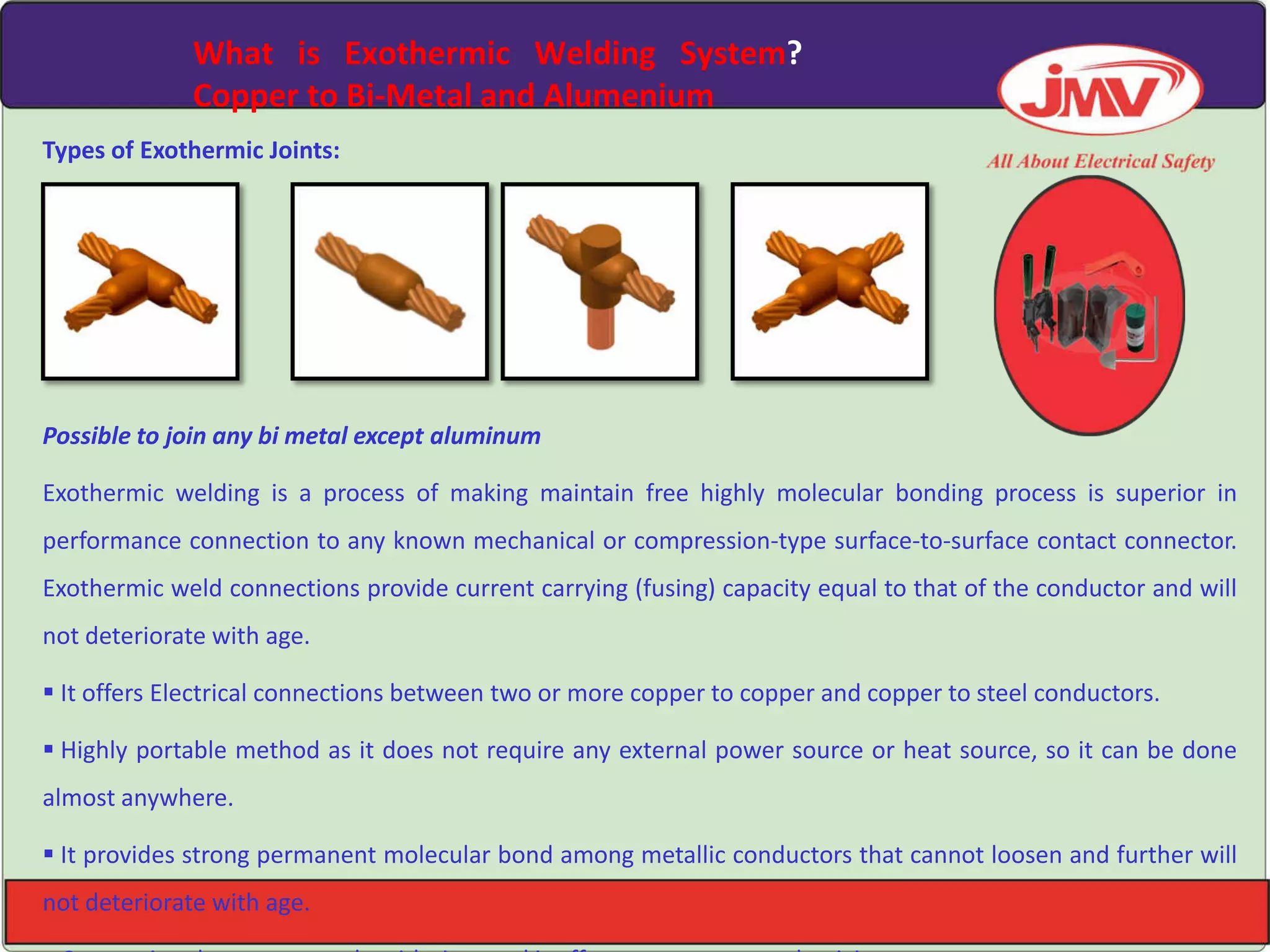

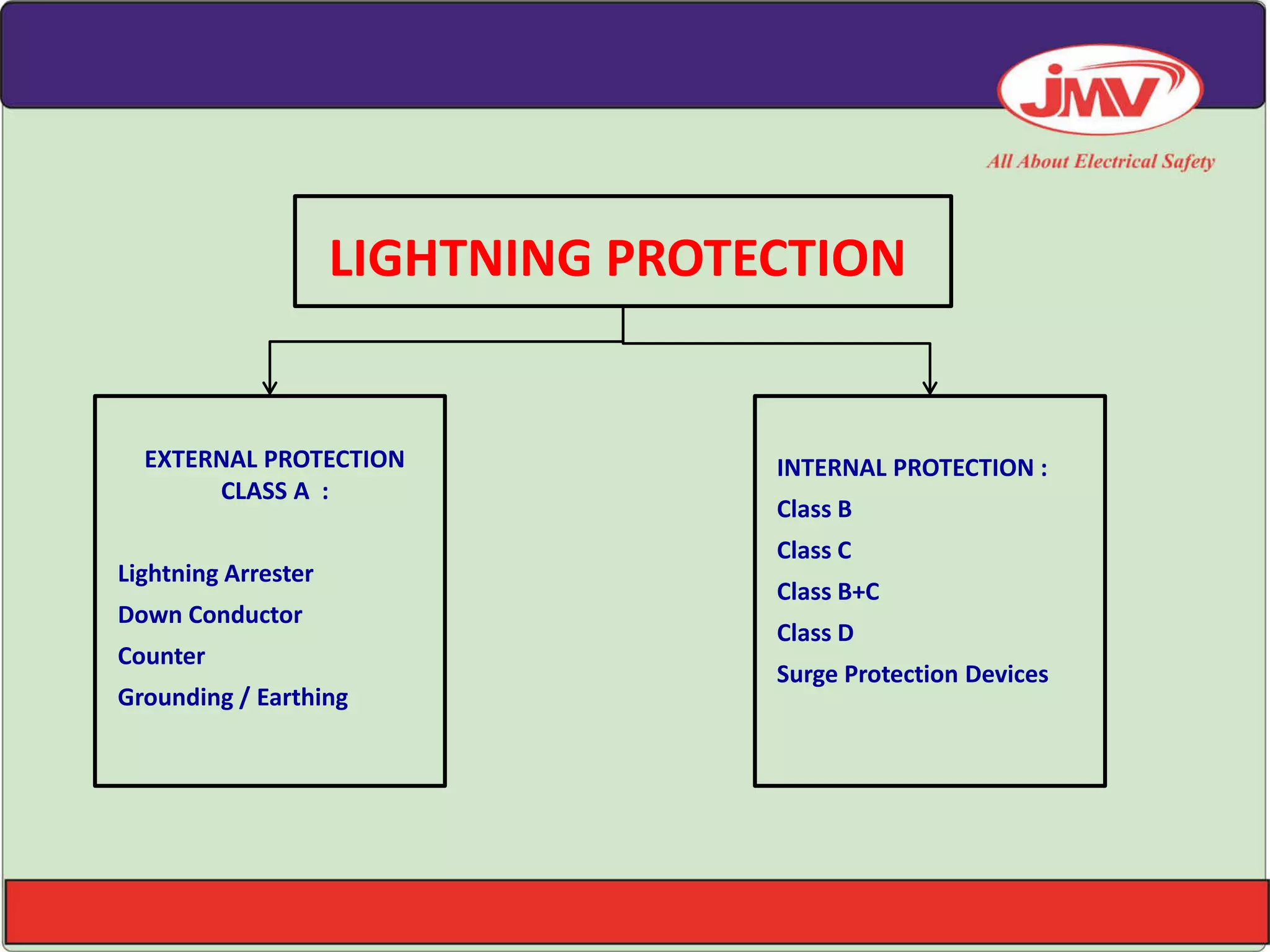

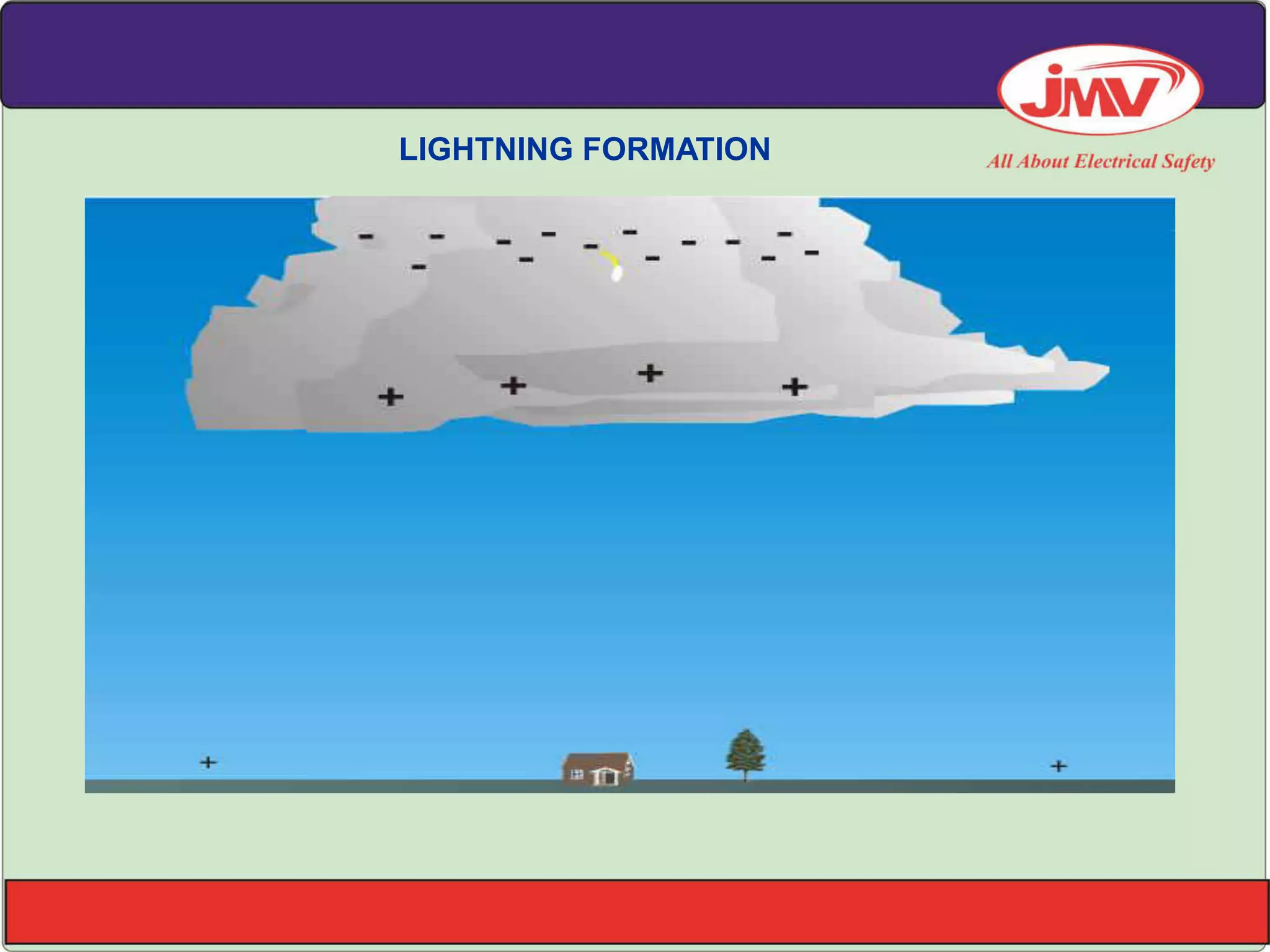

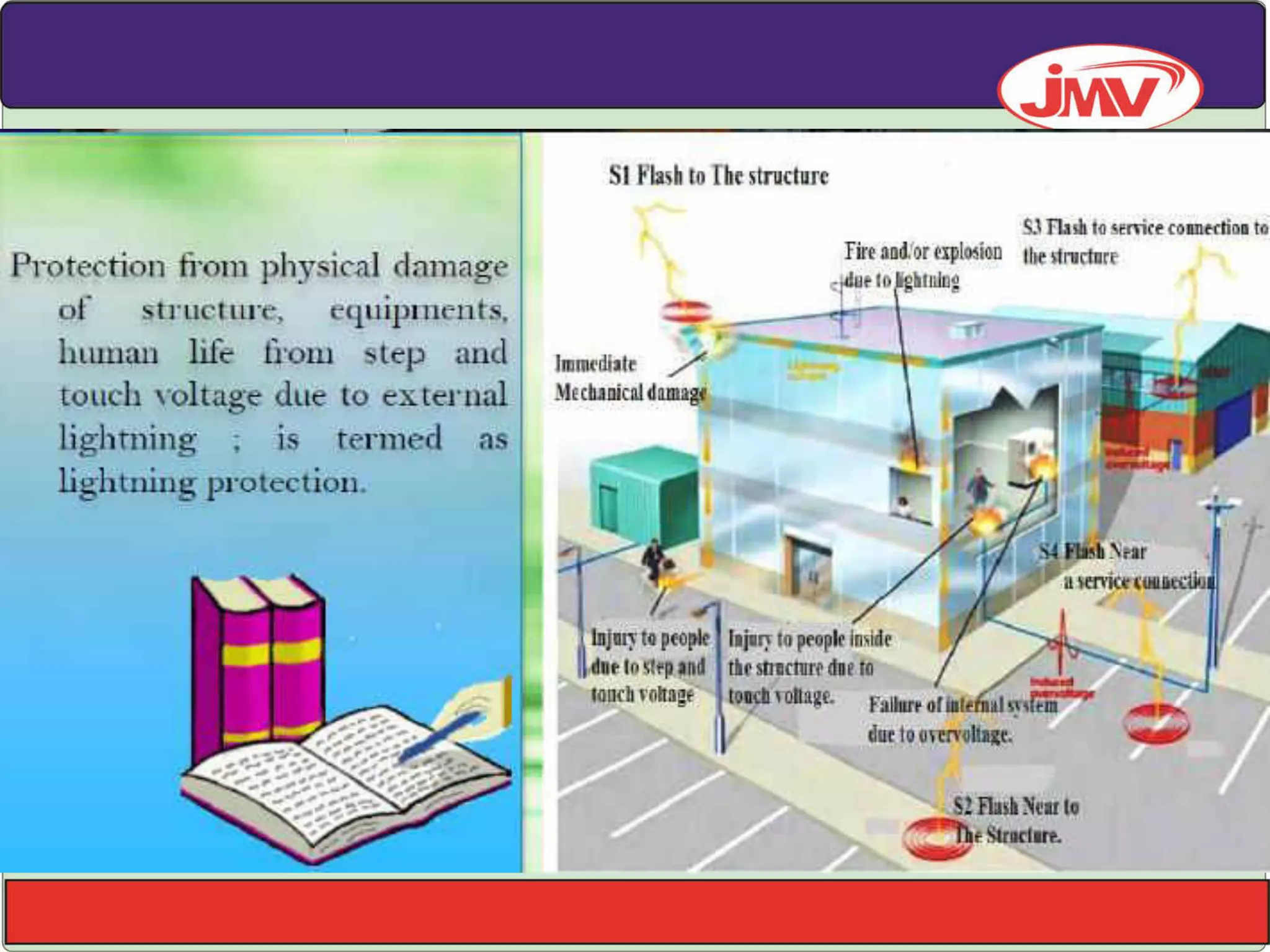

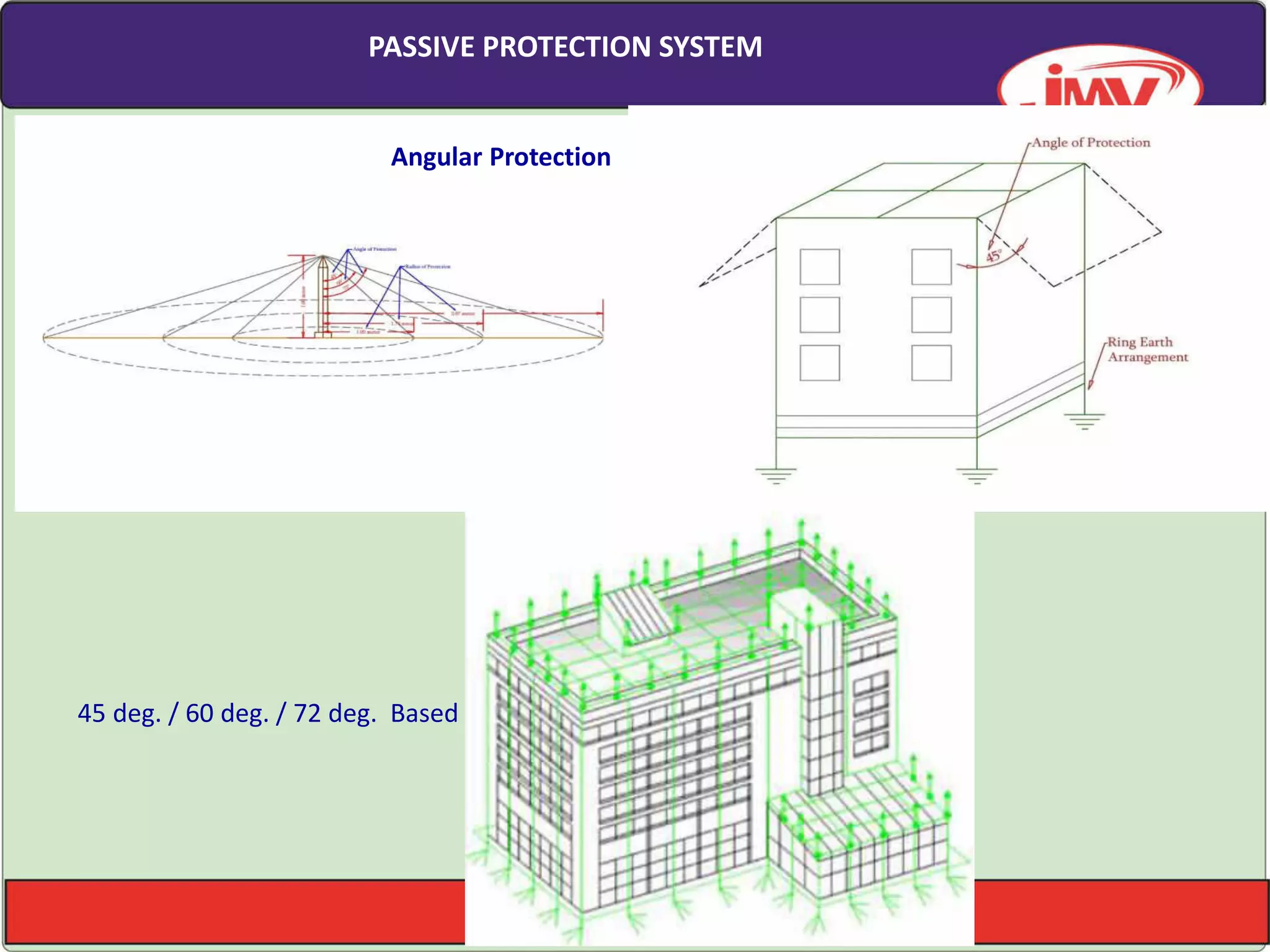

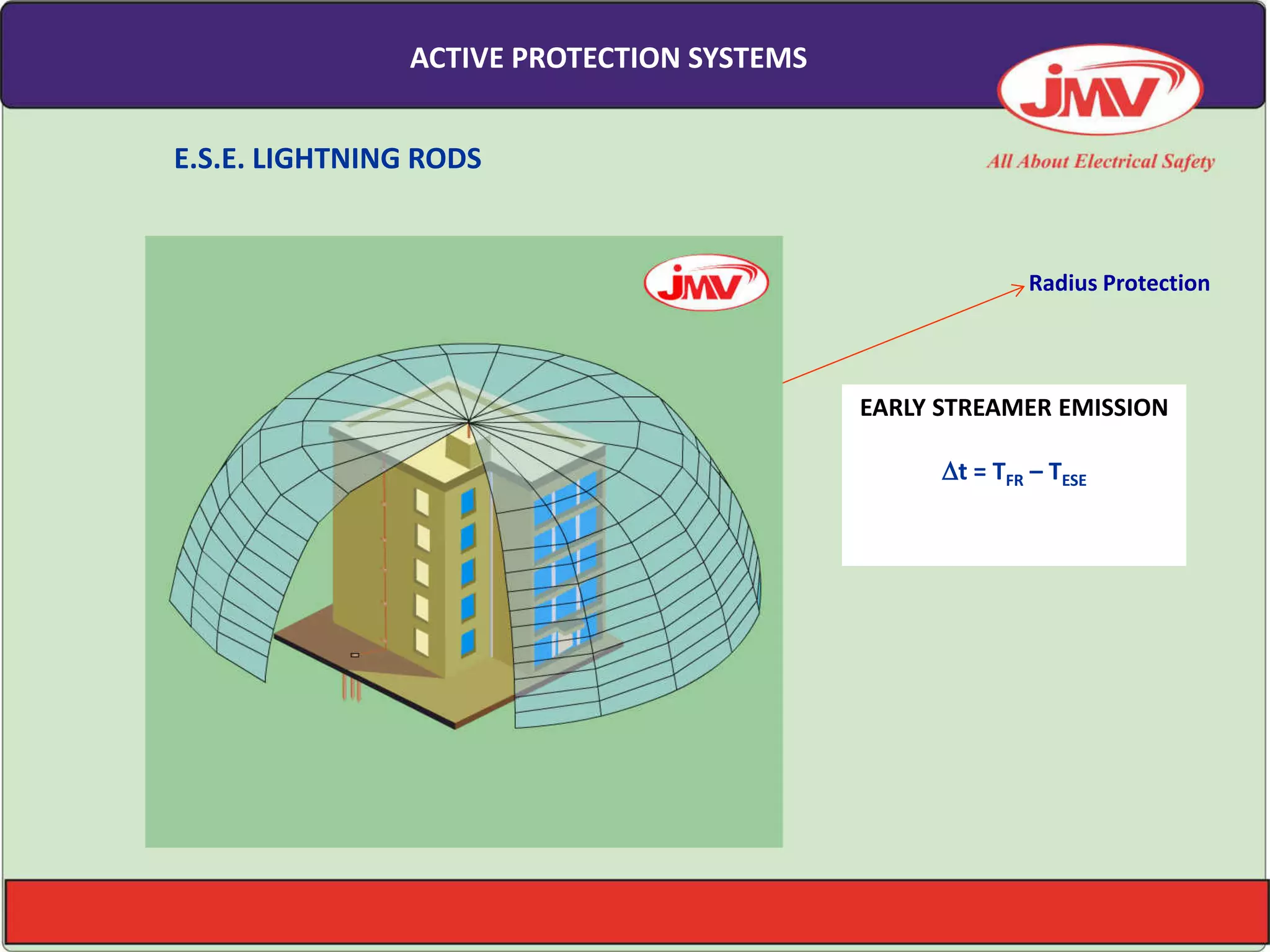

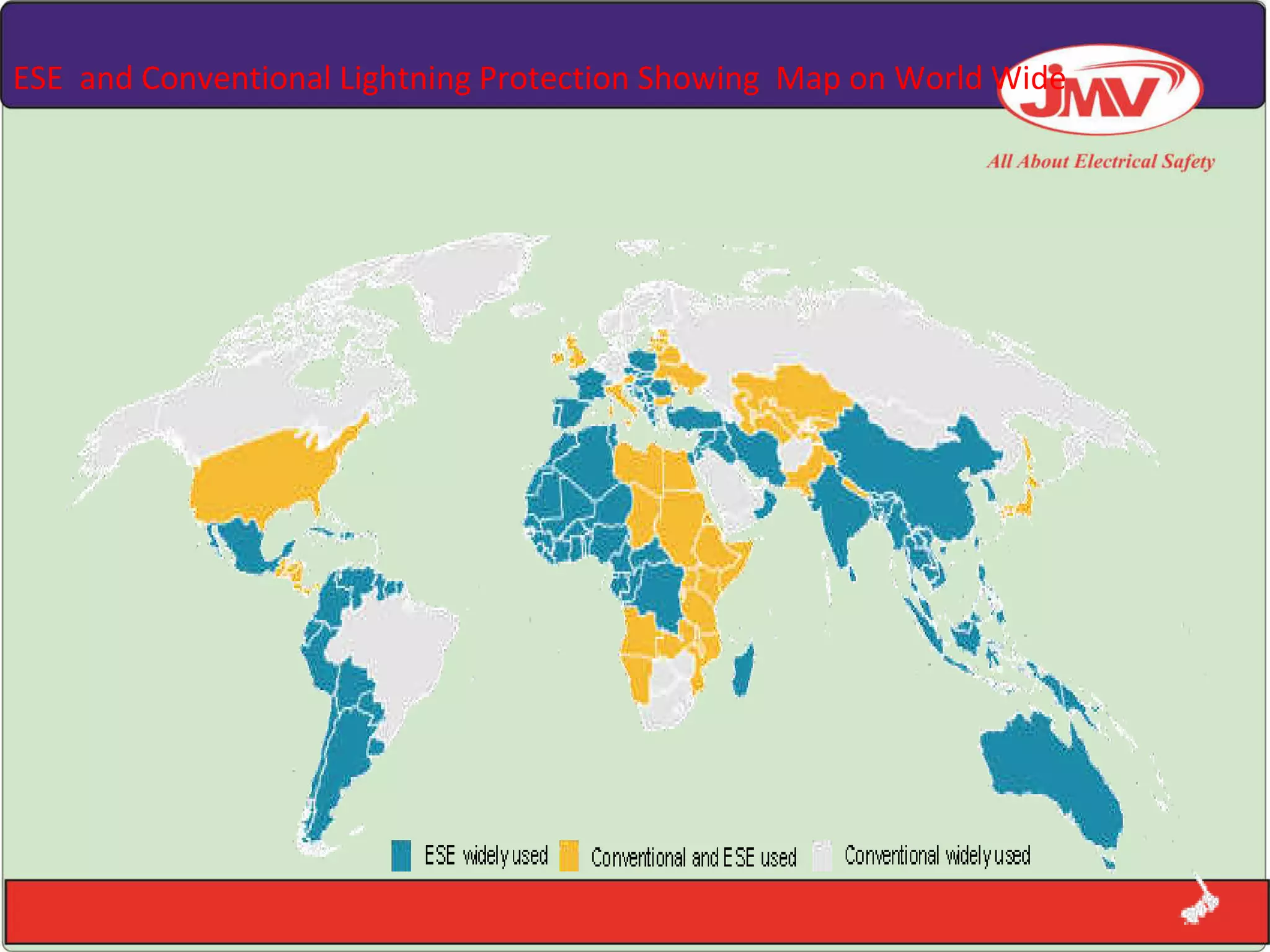

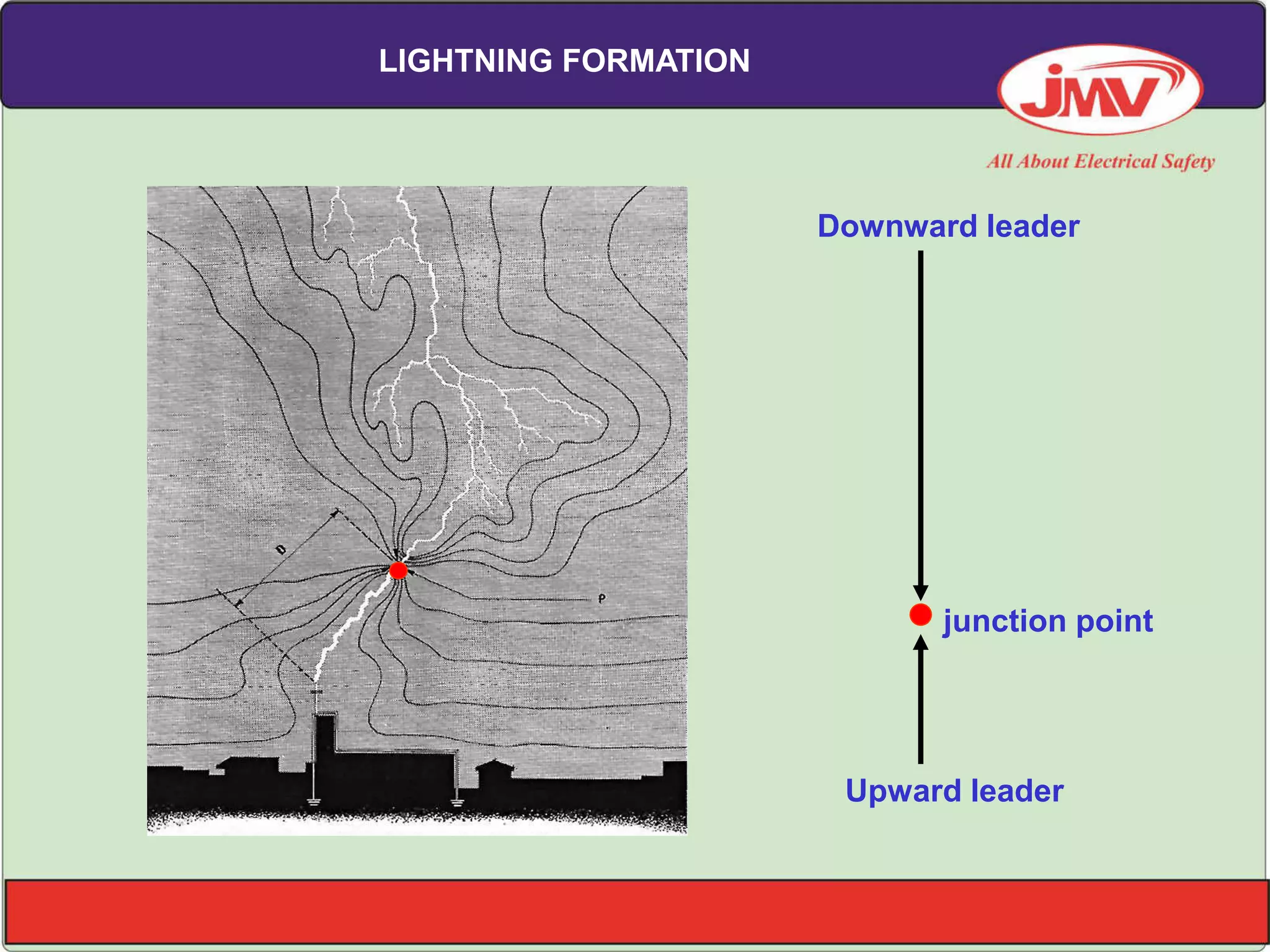

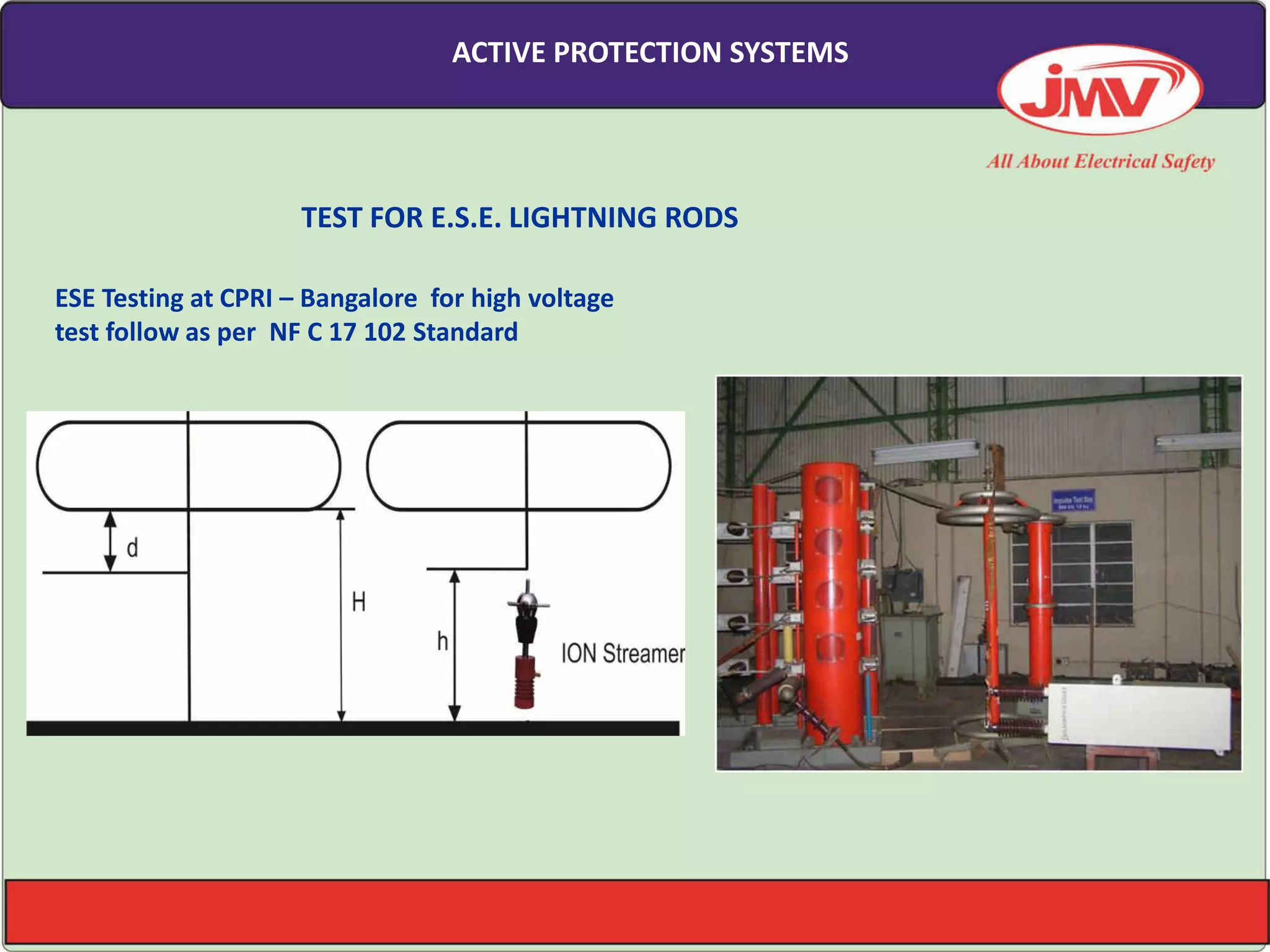

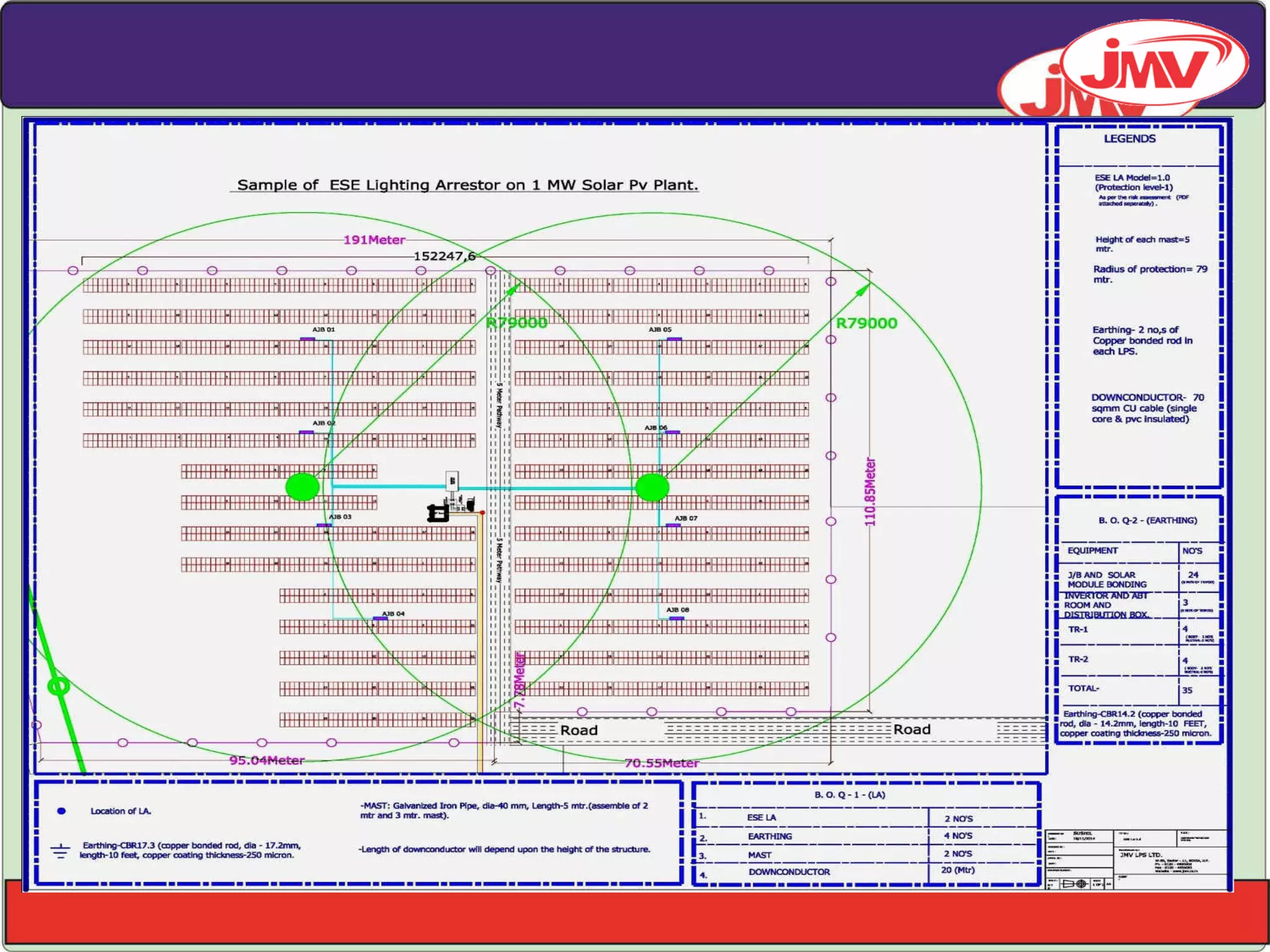

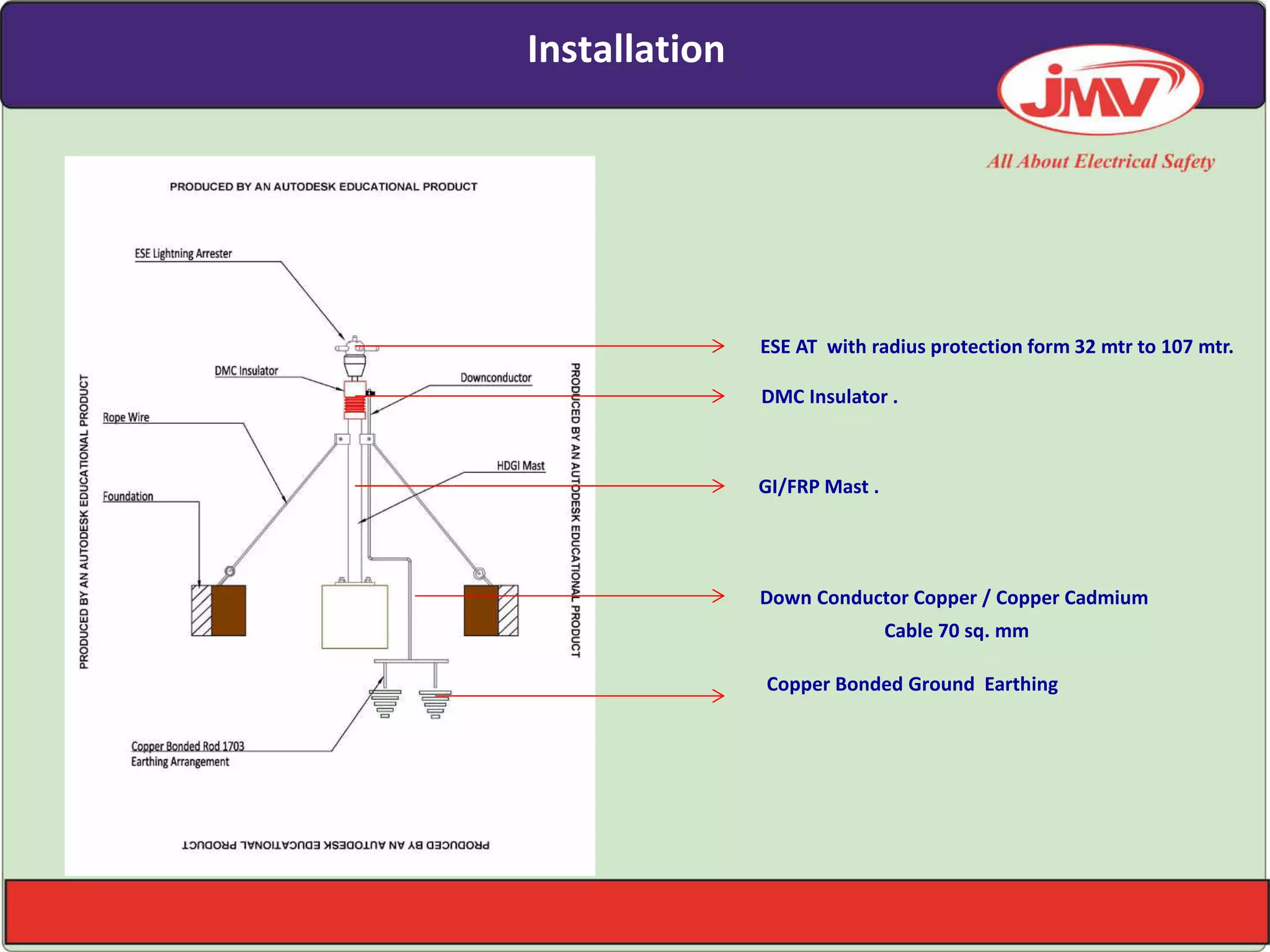

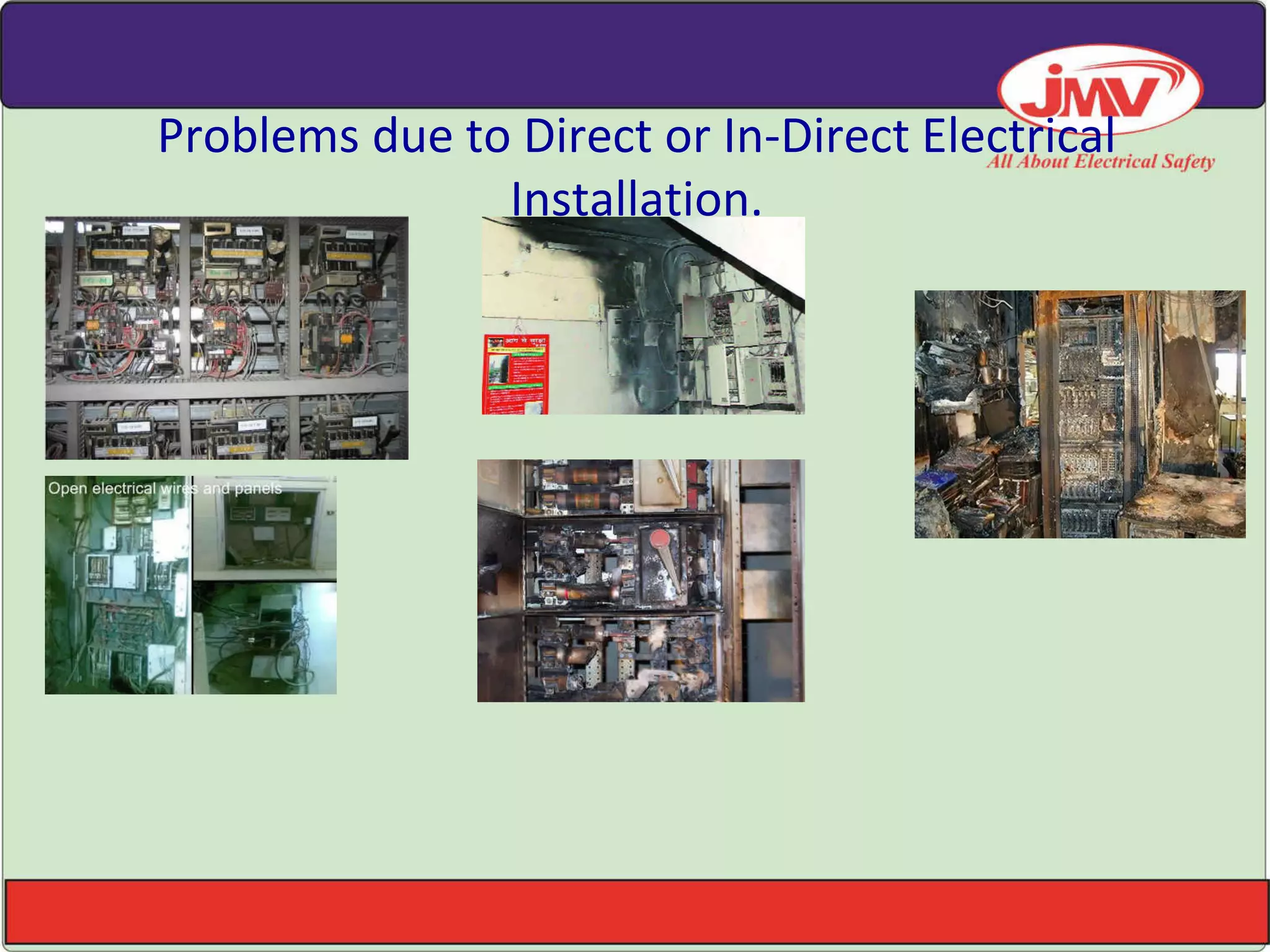

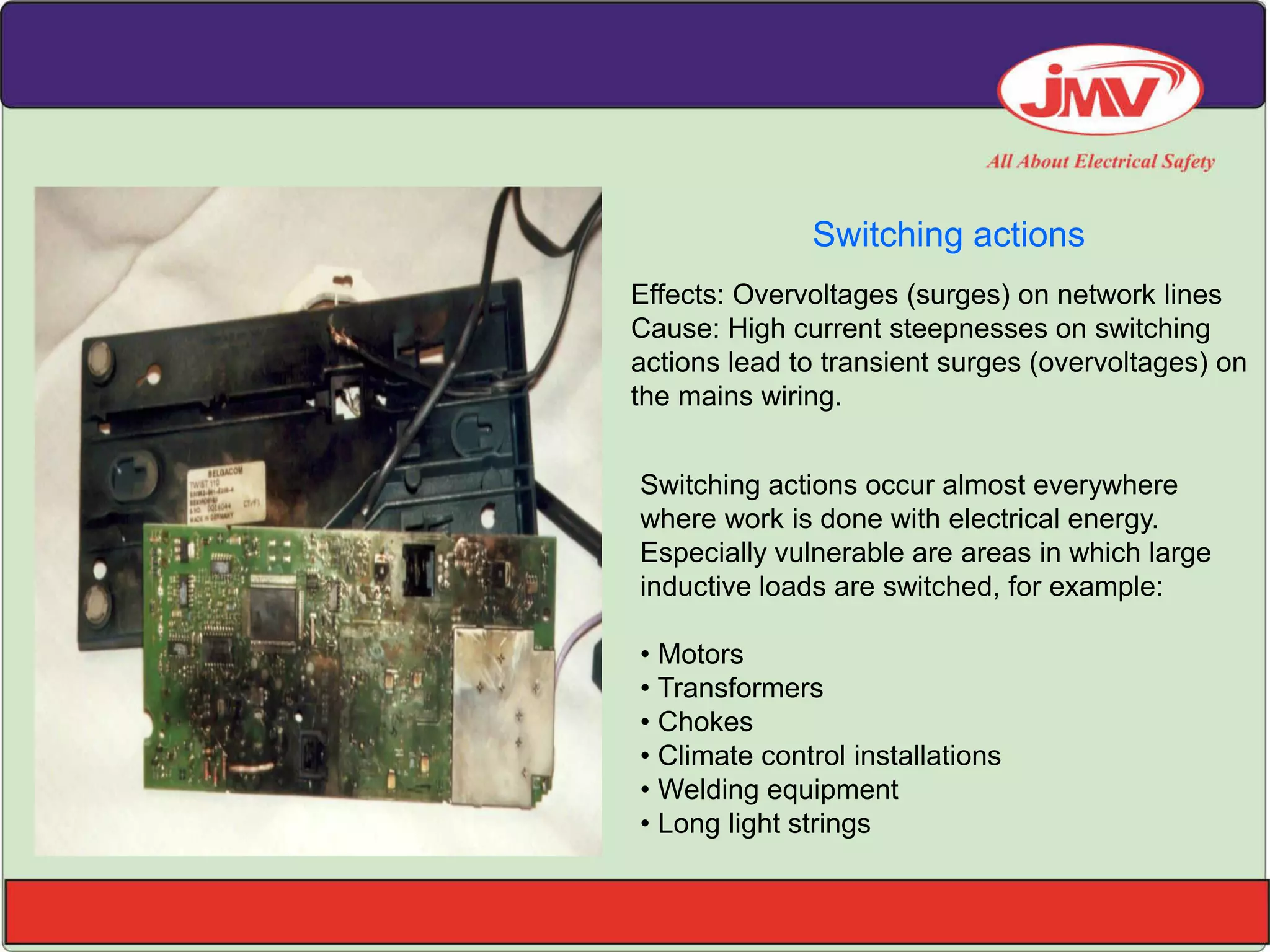

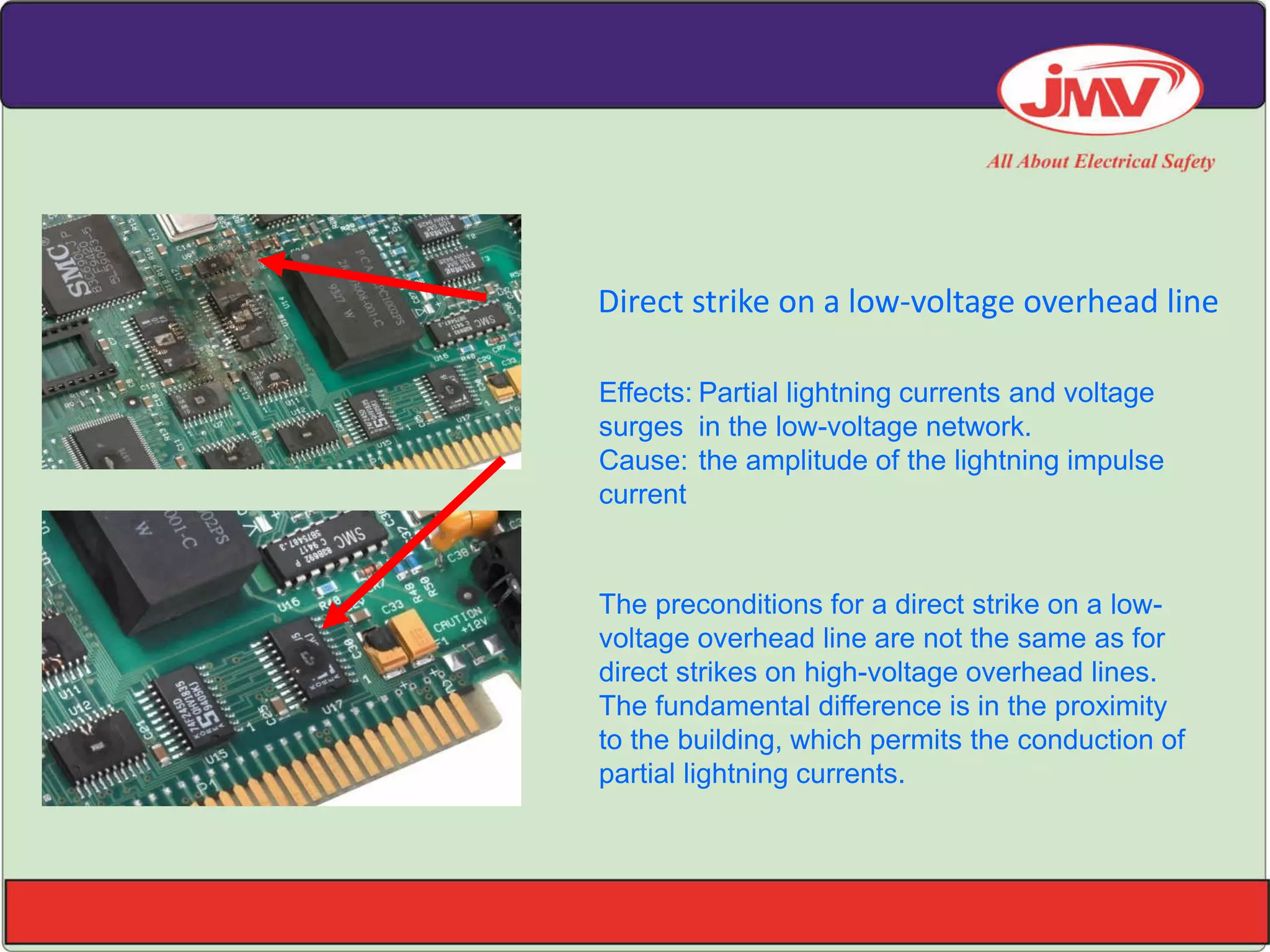

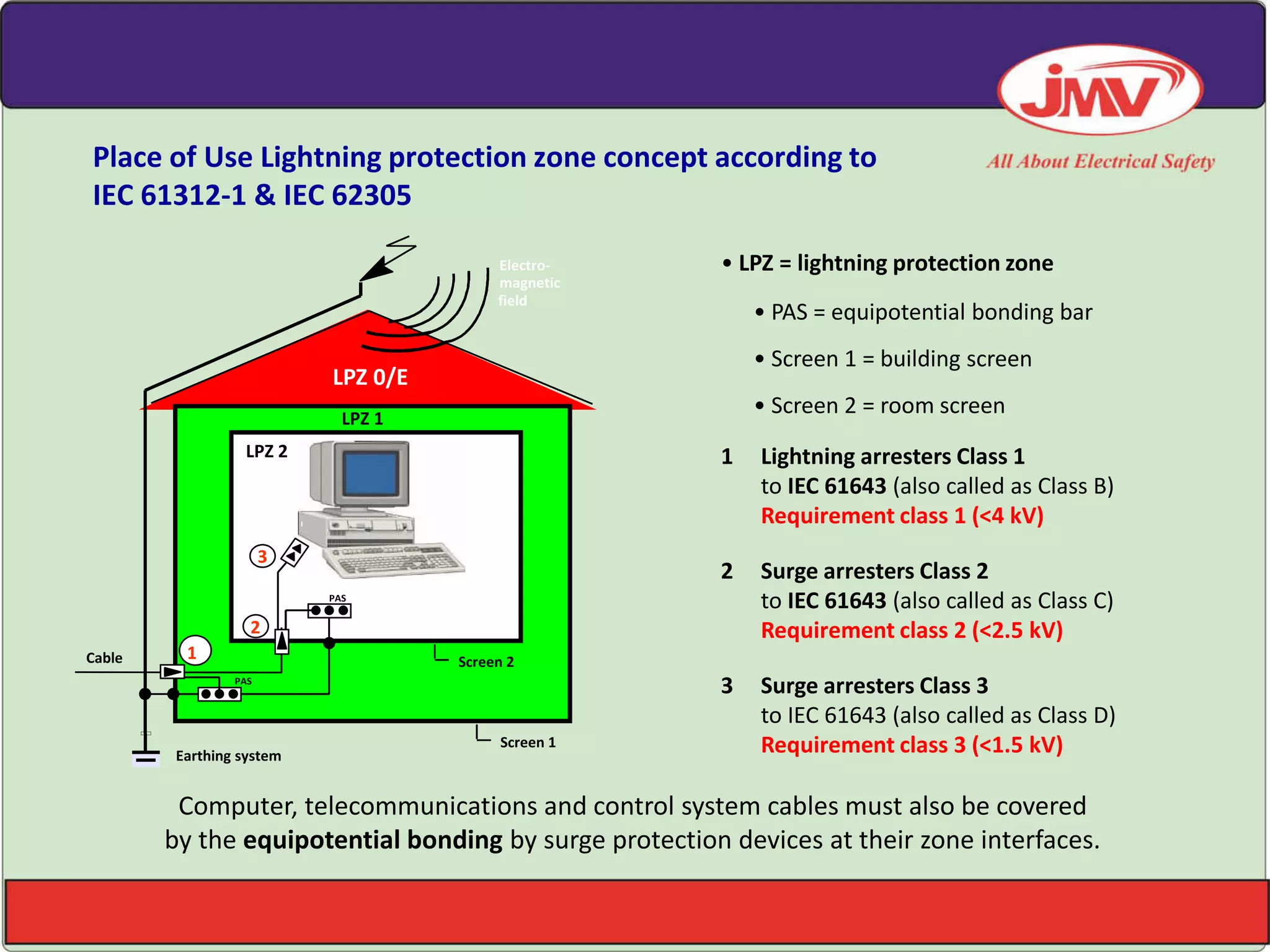

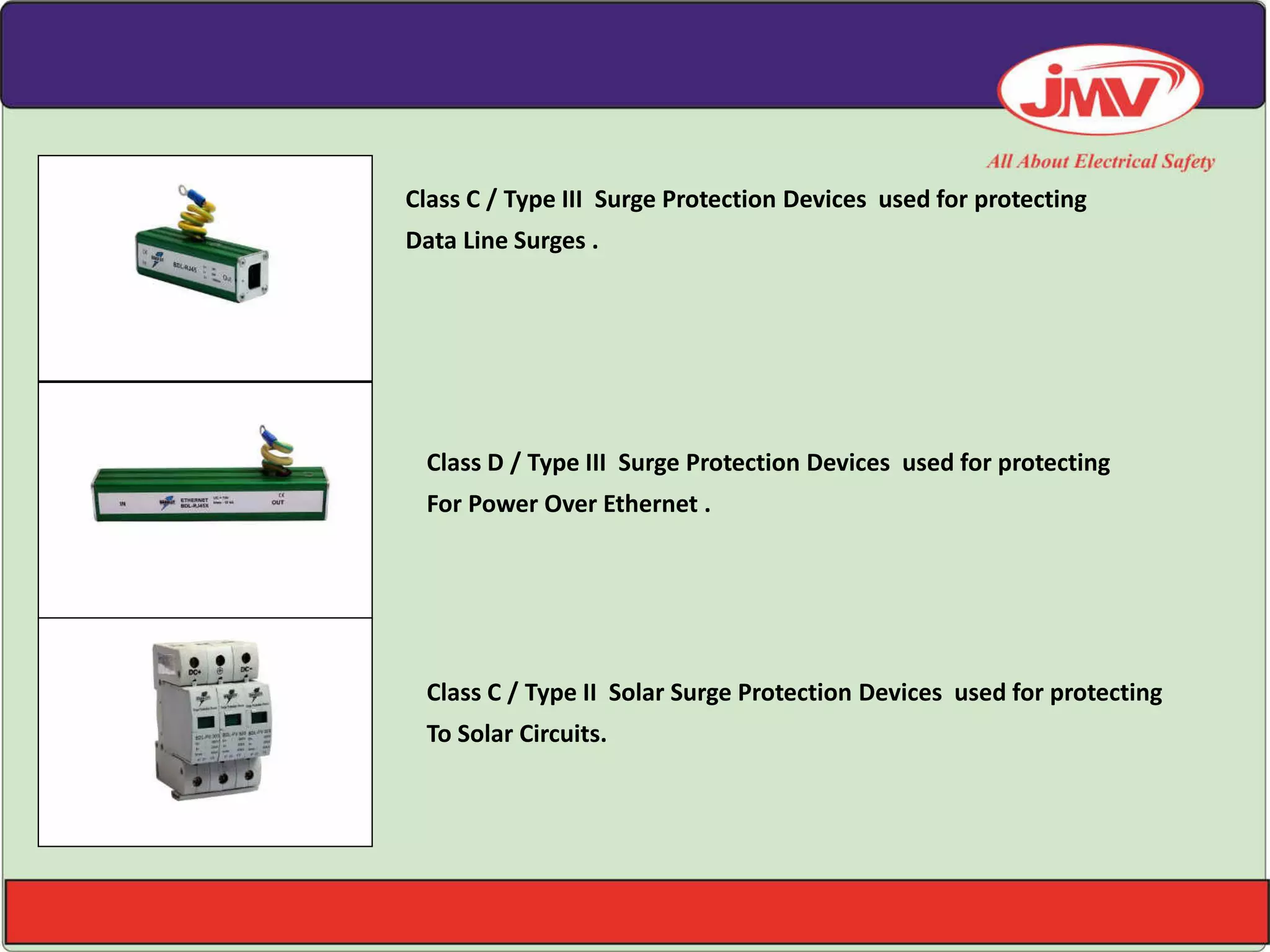

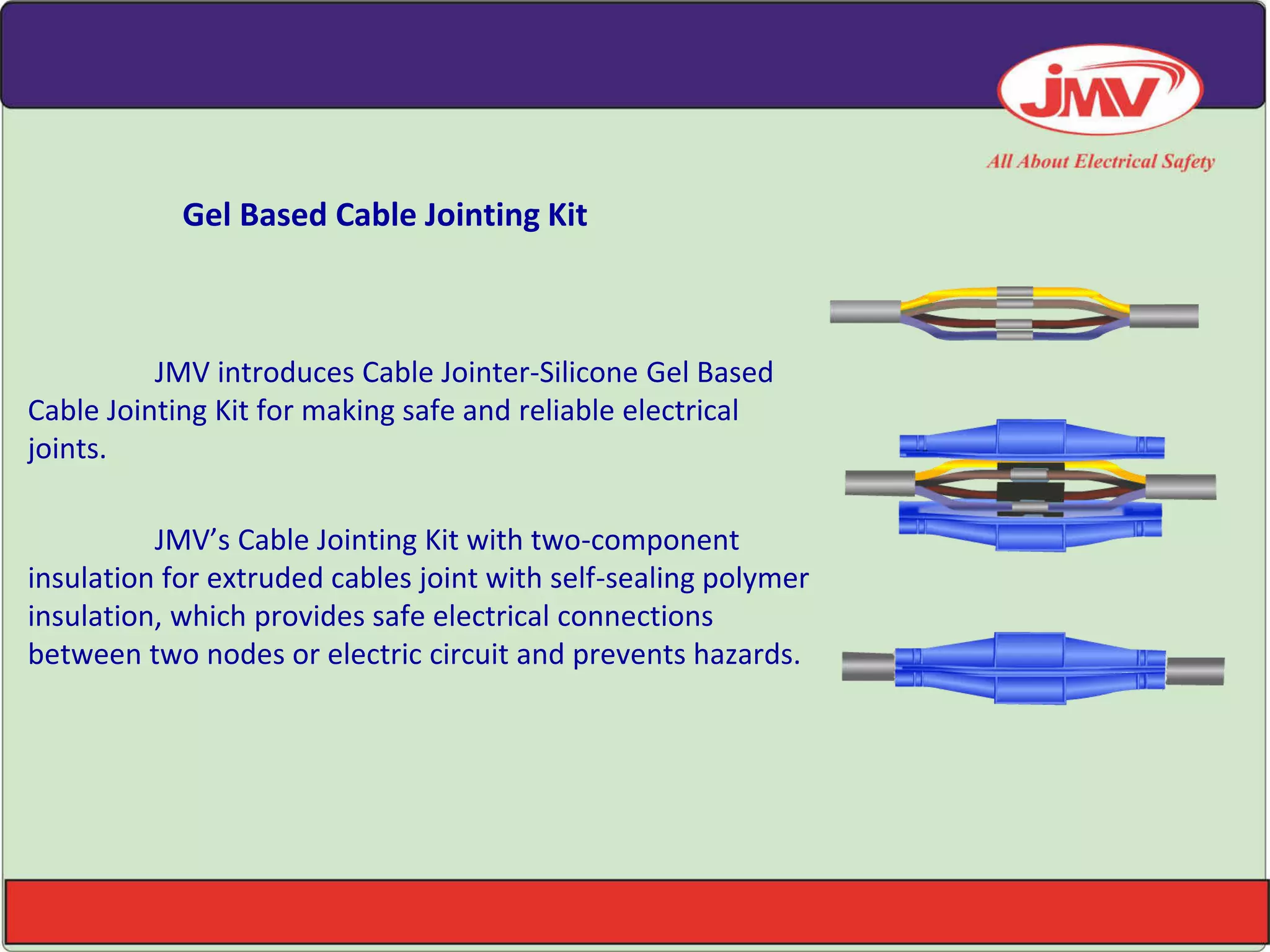

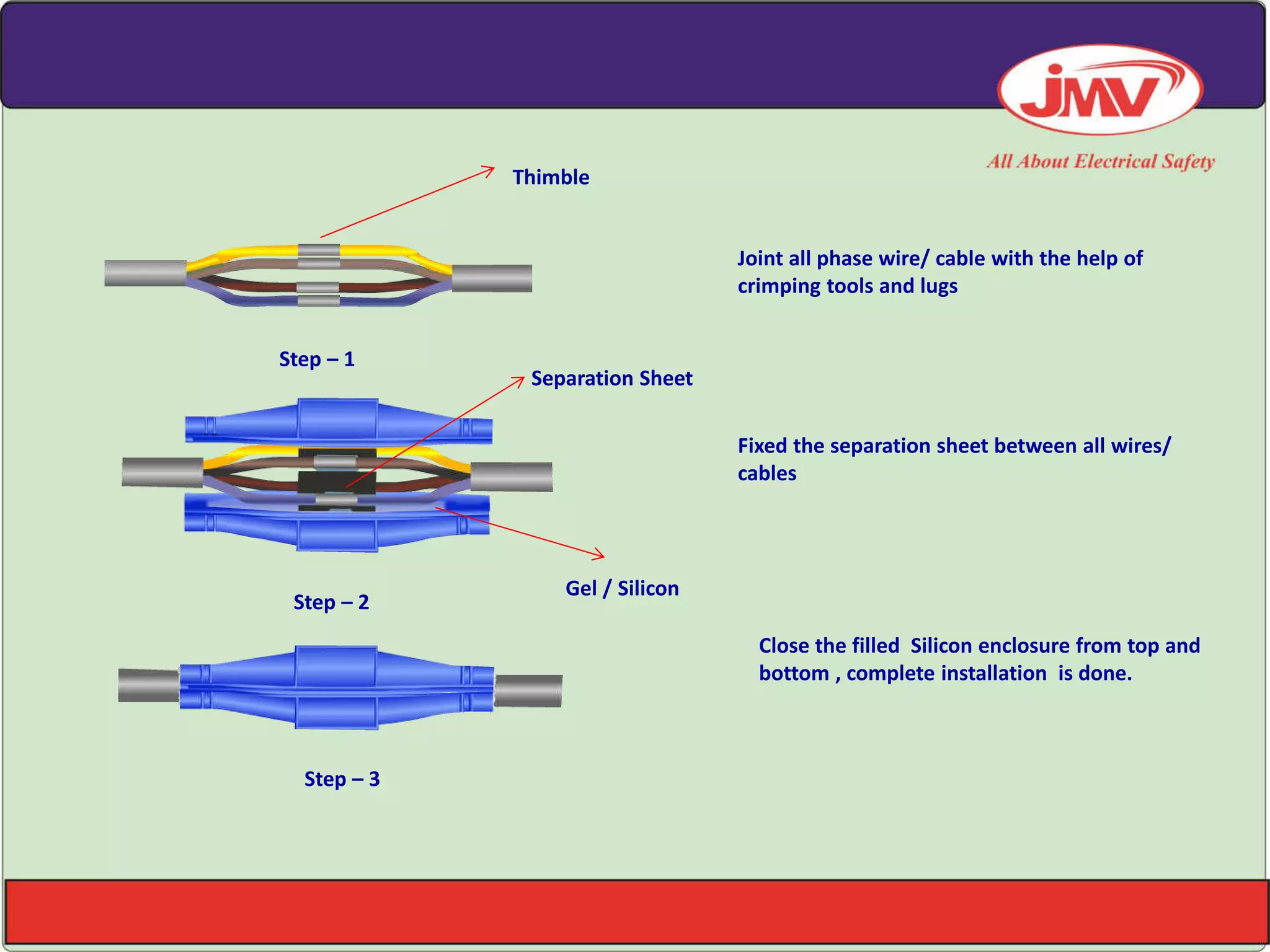

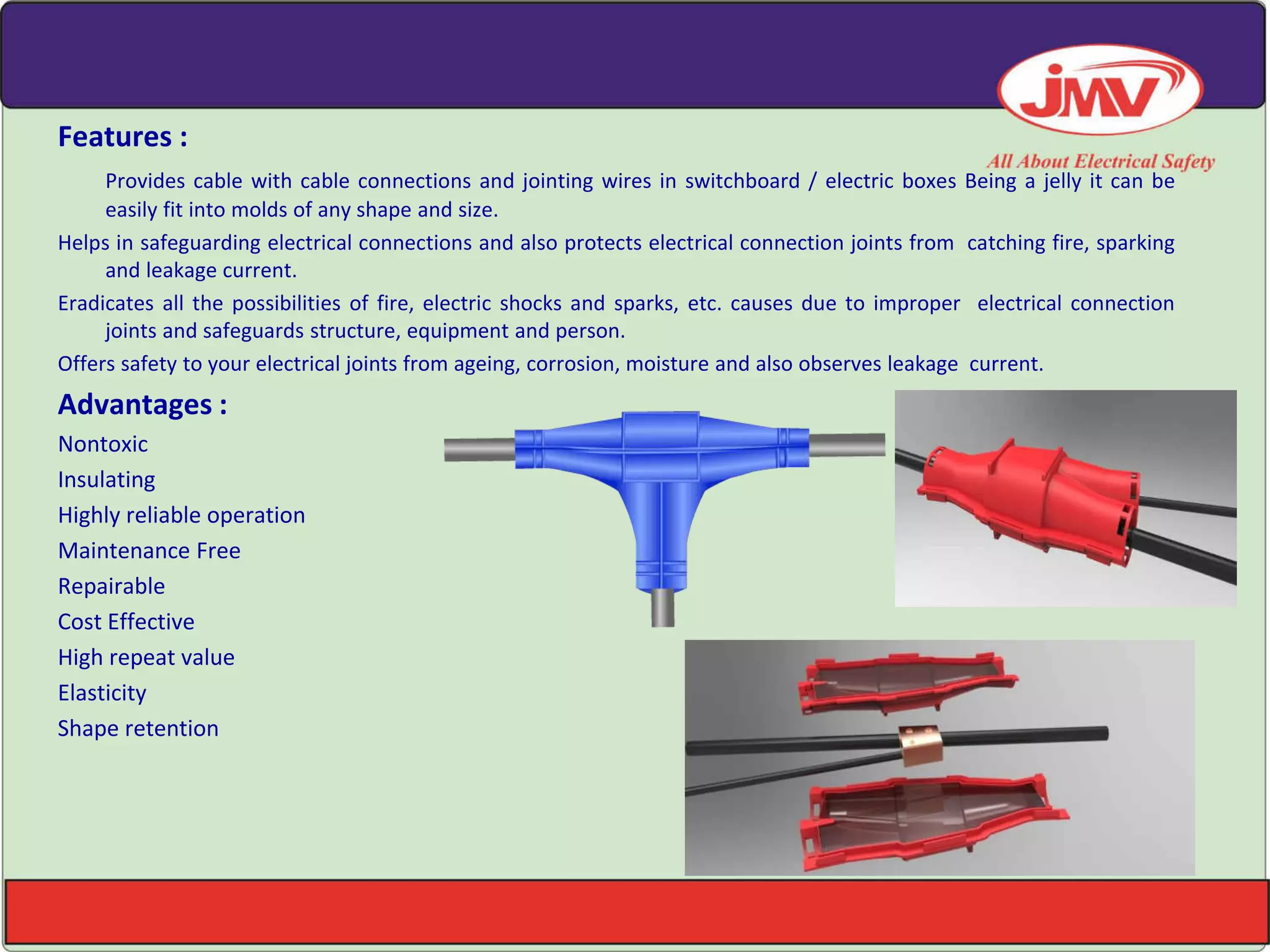

The document provides information on smart hospital projects being undertaken in India. It discusses plans to build multi-specialty hospitals in major cities with modern infrastructure like power grids, building management systems, networking, data management, and patient information systems. It emphasizes the importance of electrical safety in hospitals through practices like maintenance-free earthing, exothermic welding, surge protection, and lightning protection. The presentation promotes JMV LPS Ltd.'s electrical safety products and solutions for smart hospitals and cities like copper-bonded grounding rods, jointing kits, lightning arrestors, and surge protection devices.