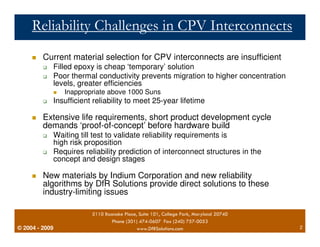

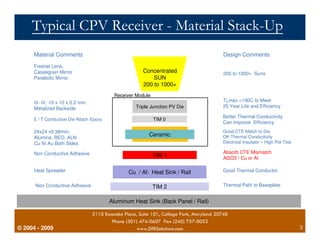

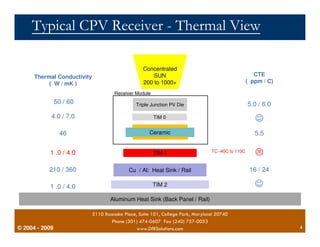

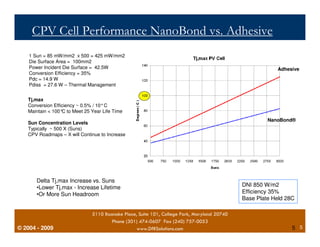

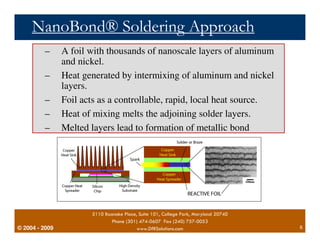

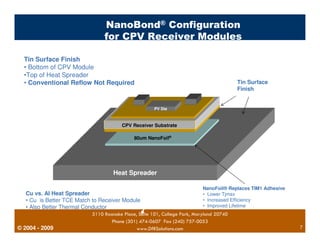

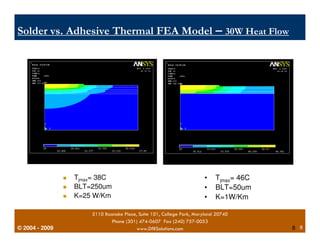

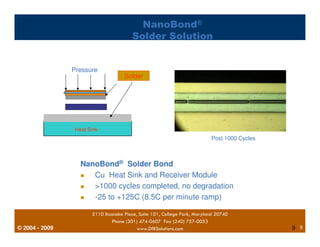

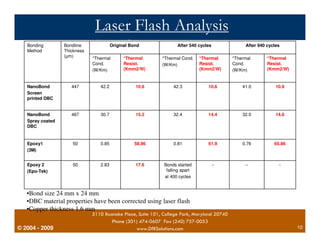

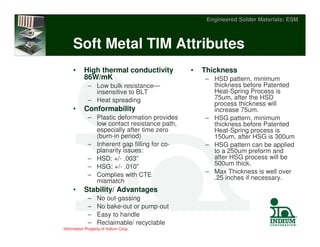

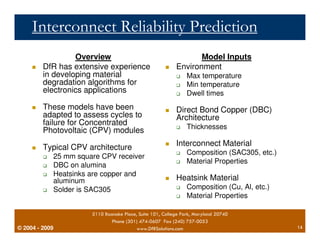

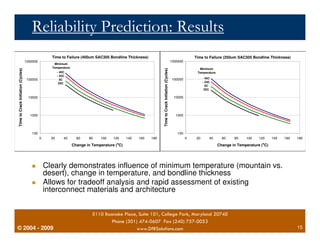

The document discusses challenges with the reliability of interconnect structures in concentrated photovoltaics (CPV) and presents solutions from DfR Solutions and Indium Corporation. Current epoxy materials used in CPV interconnects have poor thermal conductivity and insufficient reliability. DfR and Indium provide new materials like NanoBond solder and Heat Spring solder that improve thermal conductivity and exceed the reliability needs of 25-year lifetimes for CPV modules. DfR also developed reliability prediction algorithms to assess the cycles to failure of CPV module interconnects based on materials and operating conditions.