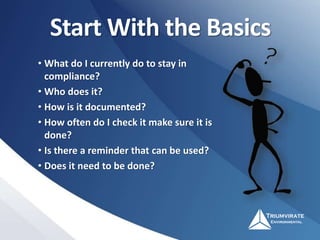

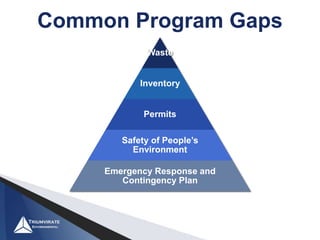

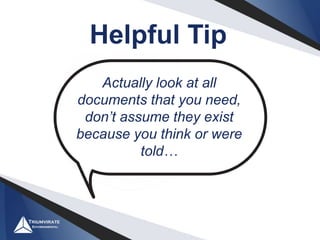

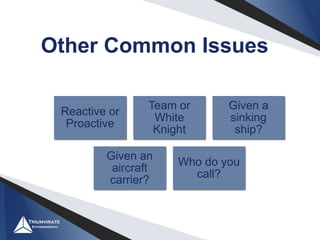

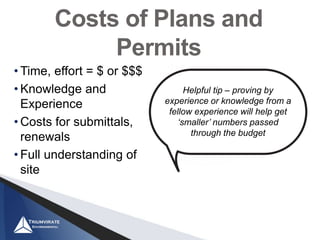

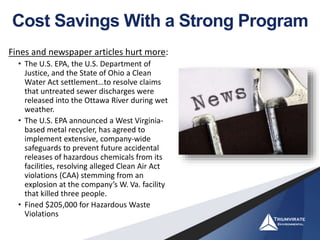

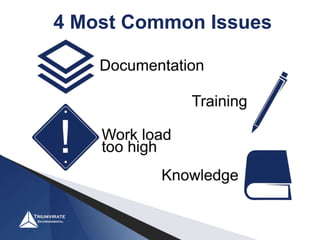

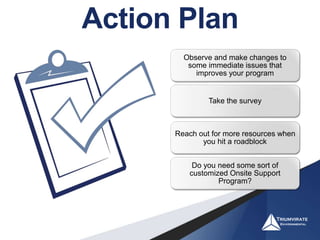

The document discusses gap analysis and improvement tactics for environmental, health, and safety (EH&S) programs. It outlines how an analysis can identify gaps in areas like waste management, inventory, permits, safety, and emergency response. Common issues include lacking or outdated documentation, reactive approaches, and not fully understanding regulatory requirements. The analysis also considers budget impacts and provides immediate tactics to address issues. Case studies demonstrate how onsite support programs can help organizations improve compliance, prepare for inspections, and benefit from ongoing review and updates to procedures.