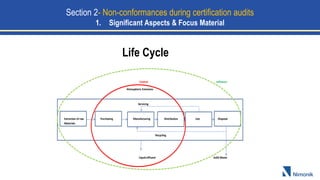

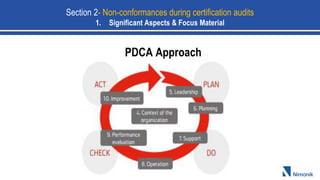

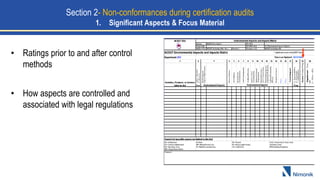

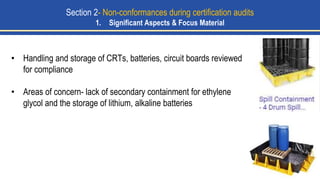

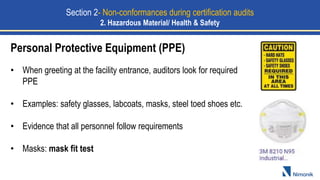

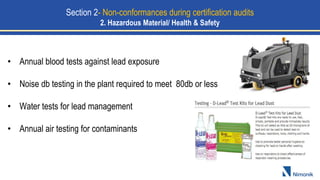

The document discusses the challenges and best practices in electronic recycling, highlighting significant non-conformances during certification audits and operational challenges in North America, especially differences between Canada and the USA. It emphasizes the importance of adapting to trends, addressing legal requirements, and improving supplier relationships in the face of fluctuating markets and evolving technology. Key issues include the handling of hazardous materials, compliance with environmental standards, and future capacity planning for recycling operations.