1) Conducting internal audits and preparing for regulatory inspections can help minimize violations and penalties. It is important to form an inspection preparedness committee and have relevant documentation organized.

2) During an inspection, the committee will coordinate schedules and daily debriefings. Facility program managers will provide documents and answer questions. Escorts will introduce inspectors and monitor interviews.

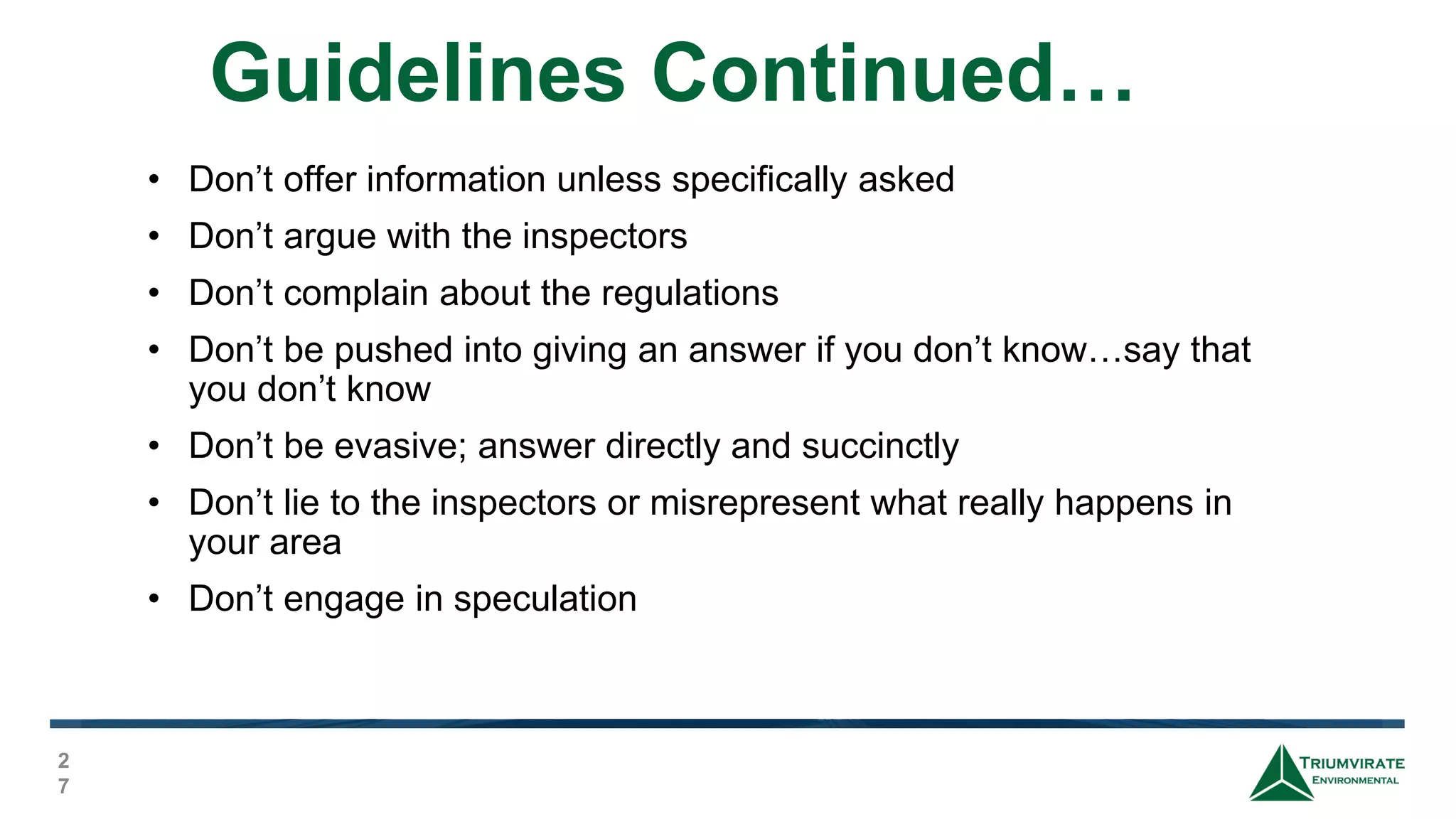

3) It is important to communicate openly yet tactfully during inspections. Inspectors should be accompanied, questions should be answered directly without speculation, and potential issues should be addressed promptly.