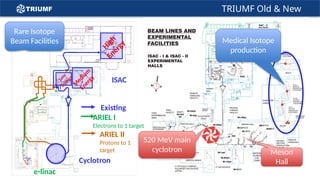

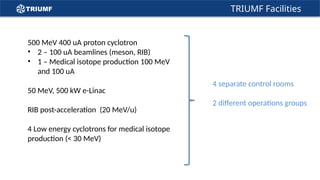

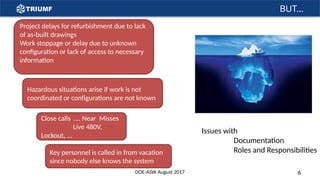

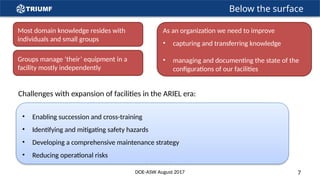

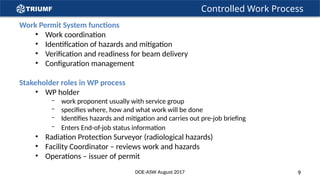

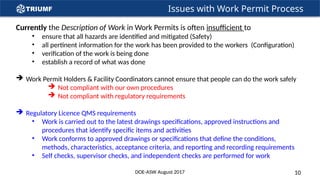

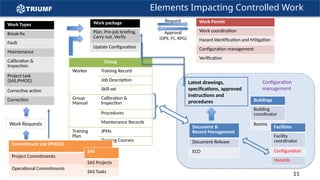

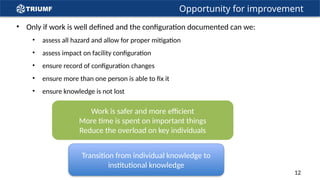

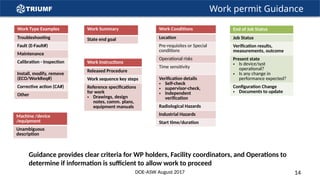

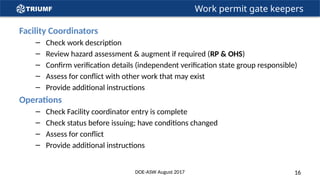

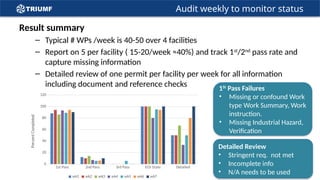

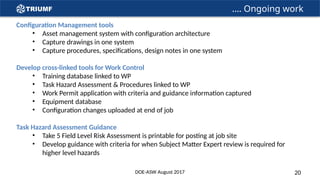

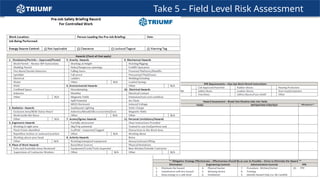

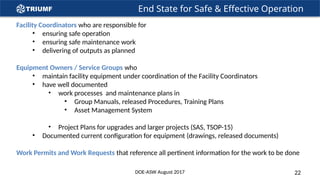

The document discusses the improvements made at TRIUMF, Canada’s national laboratory for particle and nuclear physics, focusing on enhancing the rigor and discipline of its controlled work processes. It highlights the need for better documentation, knowledge transfer, and configuration management to reduce risks and improve safety measures, detailing specific challenges and solutions through revised work permit guidelines and training adjustments. The continuous improvement efforts have led to a more efficient and safer work environment, emphasizing the importance of doing work correctly and safely over merely completing tasks quickly.