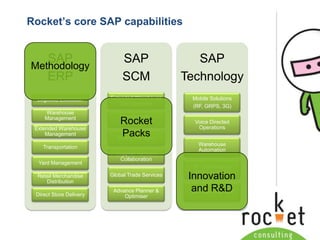

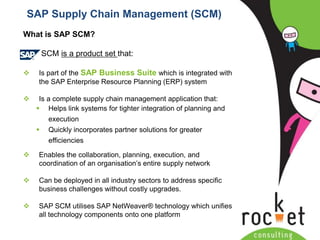

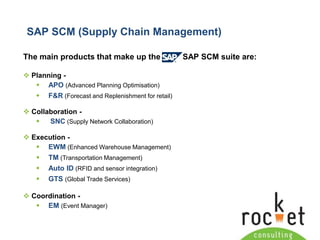

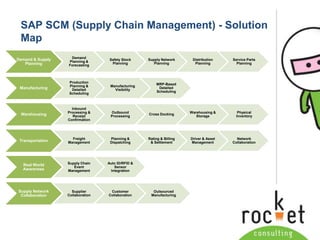

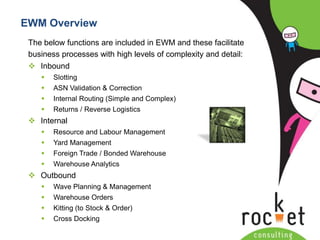

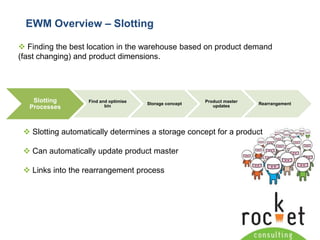

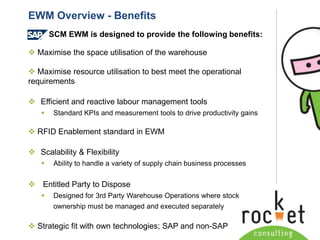

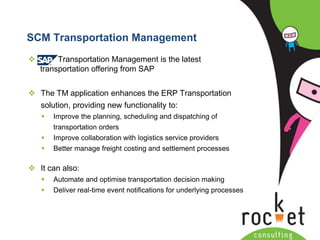

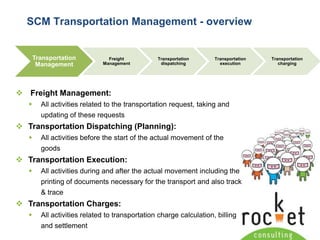

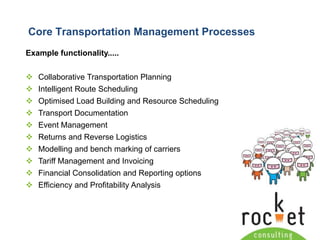

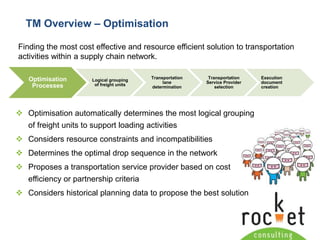

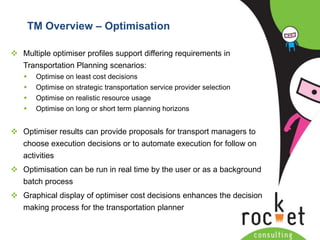

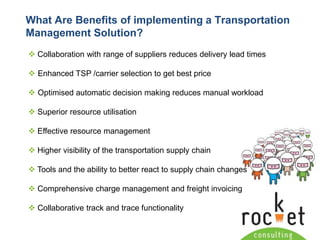

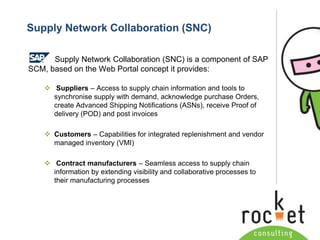

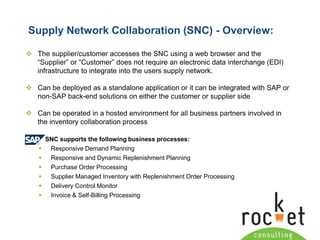

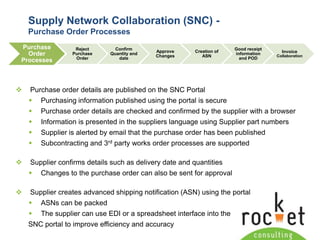

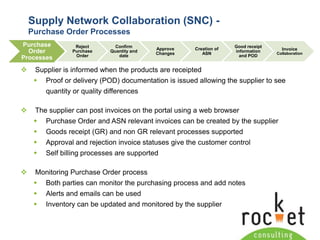

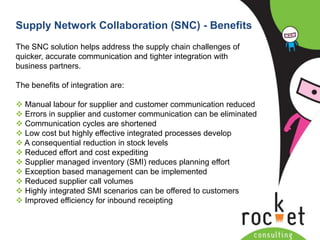

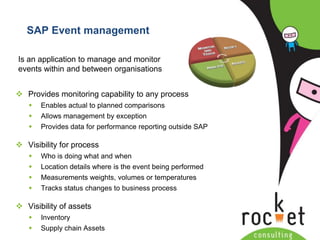

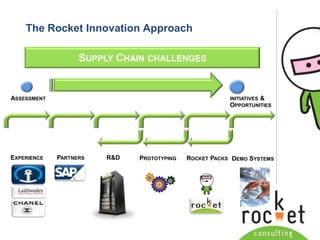

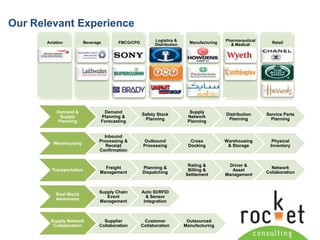

The document outlines Rocket Consulting's mission to enhance operational excellence in supply chains through SAP's integrated supply chain management solutions. It addresses significant supply chain challenges faced by businesses today, such as global competition, rising costs, and demand for better communication and integration among supply chain partners. Key SAP SCM components discussed include enhanced warehouse management, transportation management, and supply network collaboration, aimed at optimizing processes and increasing efficiency.