Spice Technology Group, Inc. provides a comprehensive overview of Electronic Data Interchange (EDI) and its benefits for retailers, manufacturers, and distributors aiming to modernize their supply chains. The document emphasizes the automation of data exchange, resulting in reduced errors and enhanced operational efficiency across various departments such as merchandising, finance, and supply chain. Additionally, it outlines a roadmap for implementing EDI, highlighting its cost-effectiveness and improved data management capabilities.

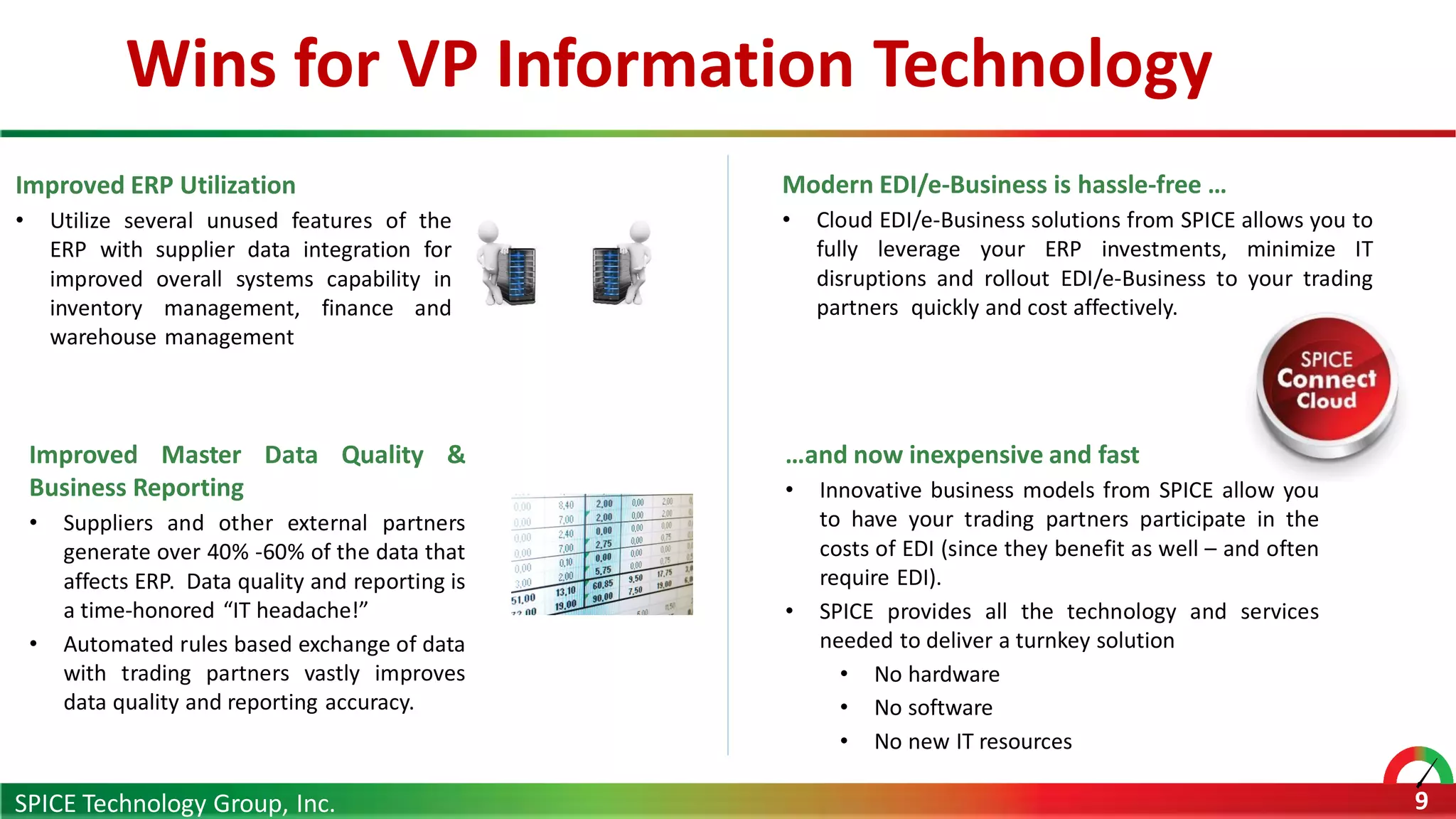

![Developing a Business Case

SPICE Technology Group, Inc. 11

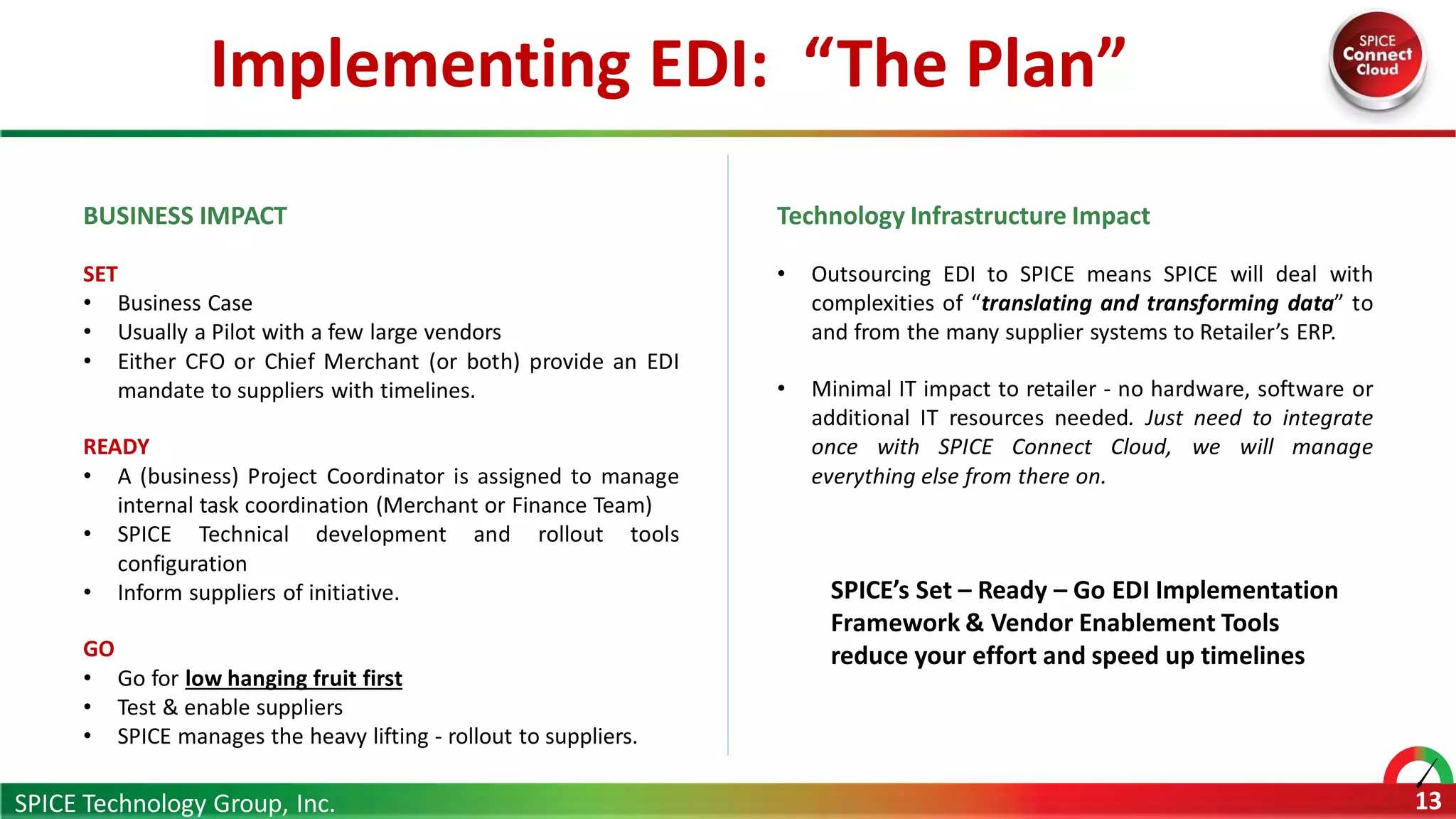

1. Reduced Lead Times

[Inventory/WOS]

2. Reduced FTE

3. Reduced Cost Per Case

4. Increased GMROI

5. Increased Turns

6. Increased Sales

7. Increased Margins

8. Increased Working Capital

9. Improved Franchisee

Experience

Your Business Case](https://image.slidesharecdn.com/buildinga21stcenturyretailsupplychain-thecaseforediinretail-spicetechnologygroup-140310124624-phpapp01/75/Building-a-21st-century-retail-supply-chain-the-case-for-edi-in-retail-spice-technology-group-11-2048.jpg)

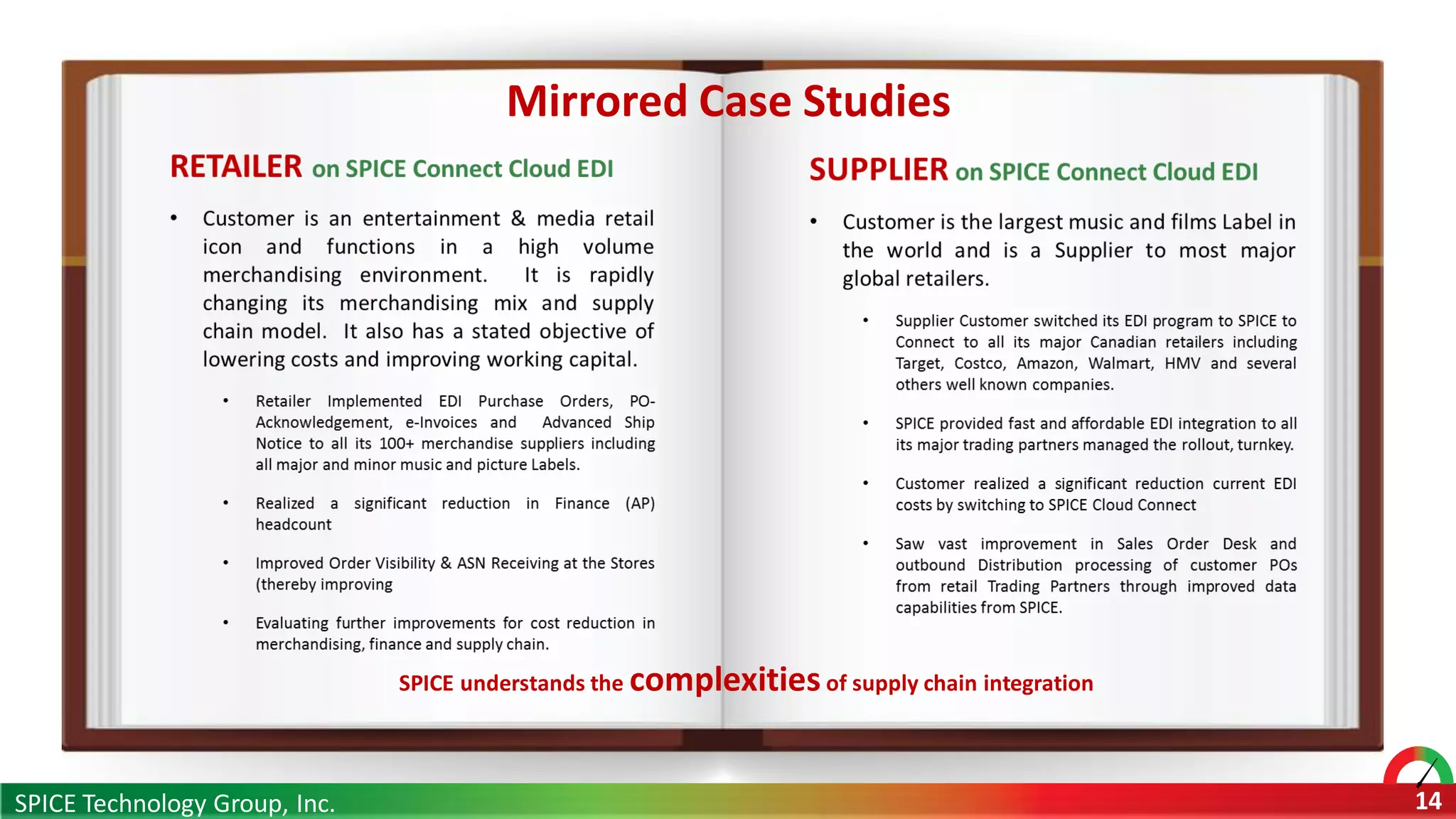

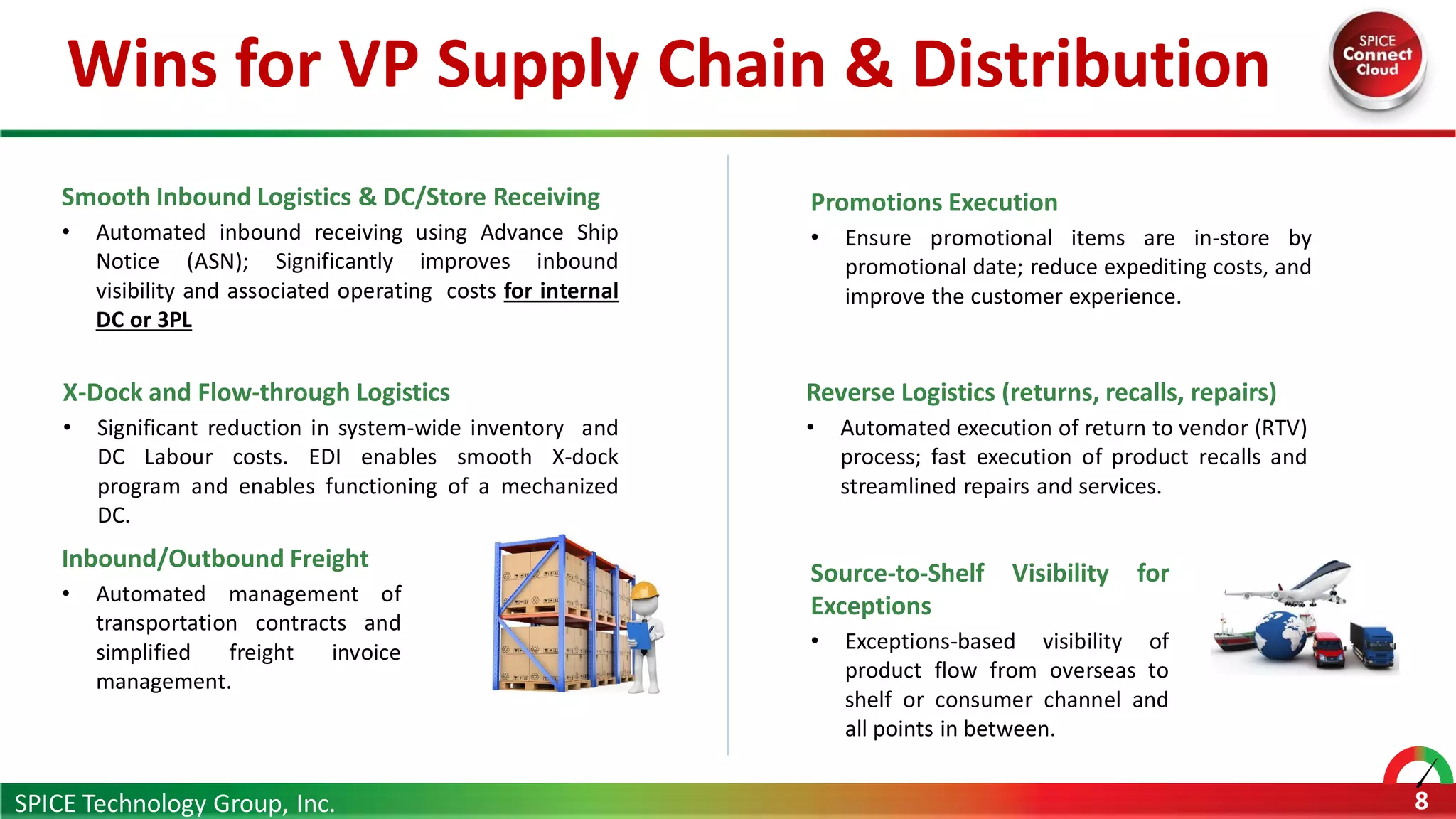

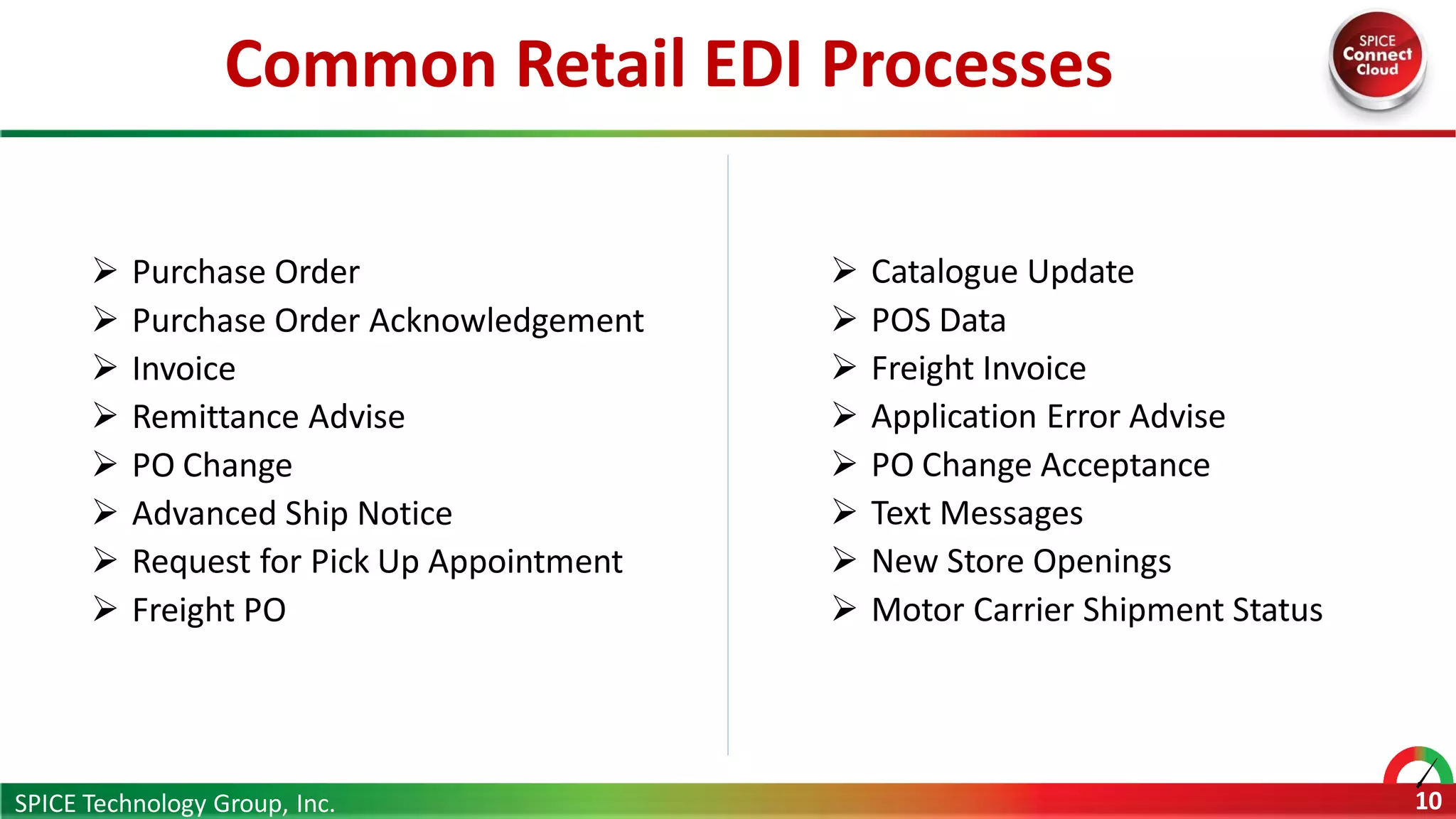

![Building a Roadmap of Benefits

SPICE Technology Group, Inc. 12

An Example of an

EDI/B2B Implementation

Roadmap

Merch. Procure-to-Pay

PO, PO-Ack, ASN, MH-10 label,

Invoice, Vendor Catalogue

Benefits: FTE, DC Labour,

Inventory

CPFR & ERS

POS Data, PO Change, Supplier PO

Change, Change Acceptance, Remittance

Advise [eliminate Invoice]

Benefits: FTE, DC Labour, Inventory

Scan-based Trading

Implement for certain categories

Supplier Score-carding

Benefits: FTE, DC Labour, Inventory

6-12 months

6-12 months

6-12 months

Capture low

hanging fruit](https://image.slidesharecdn.com/buildinga21stcenturyretailsupplychain-thecaseforediinretail-spicetechnologygroup-140310124624-phpapp01/75/Building-a-21st-century-retail-supply-chain-the-case-for-edi-in-retail-spice-technology-group-12-2048.jpg)