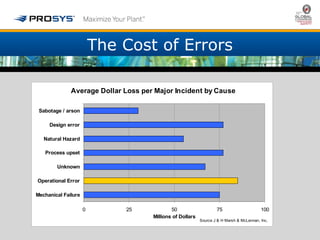

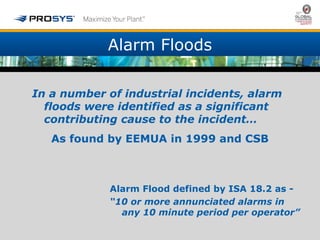

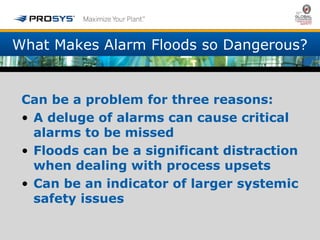

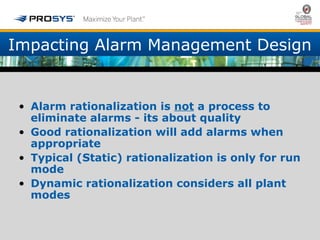

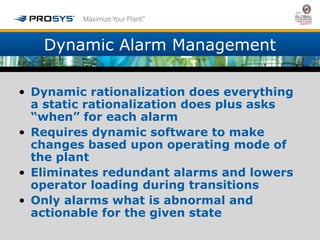

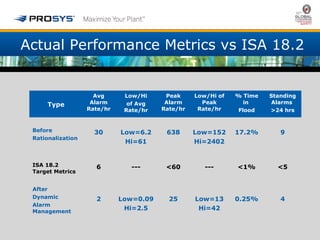

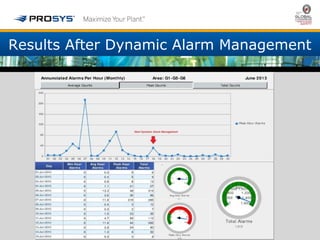

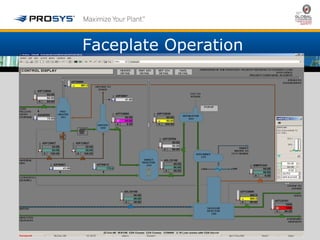

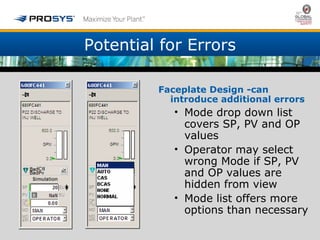

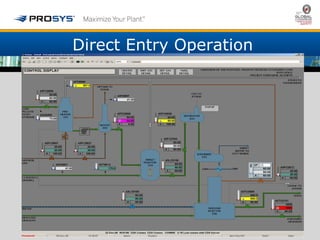

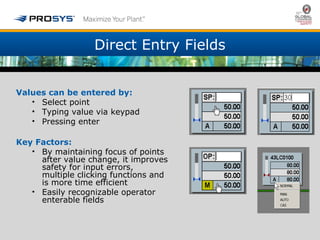

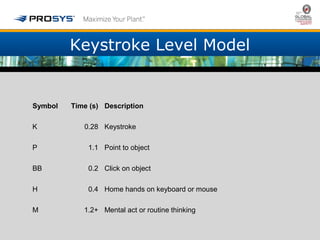

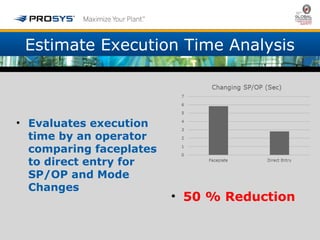

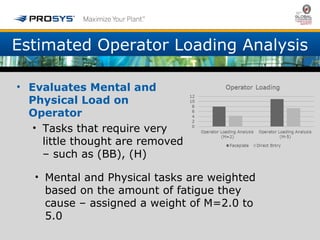

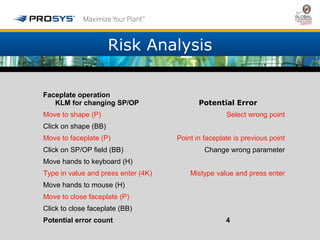

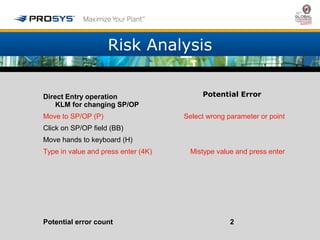

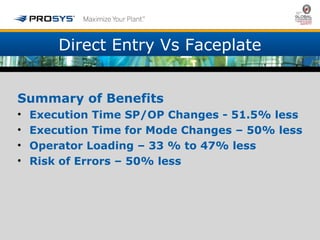

Operator errors are a major cause of industrial incidents and cost billions per year. Poor alarm management and operator interface designs can set operators up to make errors. Alarm floods overwhelm operators and dynamic alarm management that accounts for different plant states can reduce alarm rates and time in flood. Faceplates with drop-down menus and multiple open windows increase error risk but direct entry of values into clearly labeled fields reduces errors by 50% while also lowering operator workload and execution times for tasks by over 50%. Redesigning alarm and control systems can help prevent predictable and preventable operator errors.