Embed presentation

Download to read offline

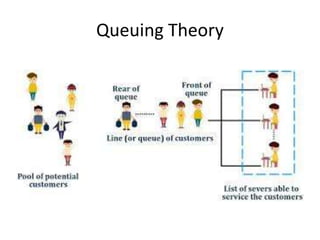

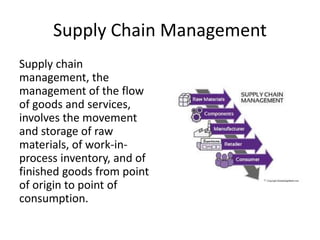

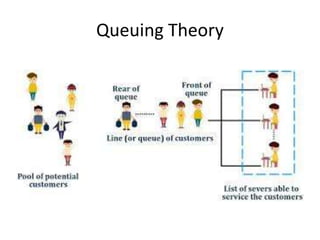

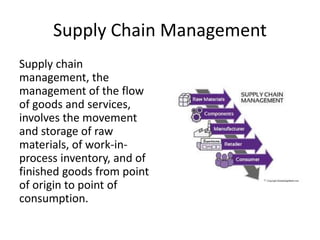

The document covers key elements of operations management, focusing on process improvement, productivity enhancement, and inventory management. It includes discussions on manufacturing strategies, queuing theory, and quality management practices like Six Sigma and ISO certifications. Additionally, it highlights the importance of project management and supply chain management in efficiently managing the flow of goods and services.