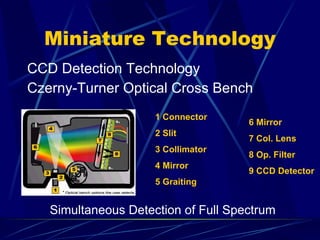

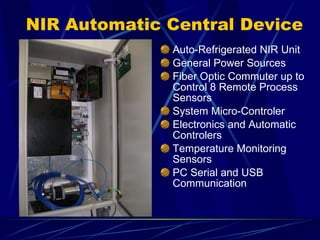

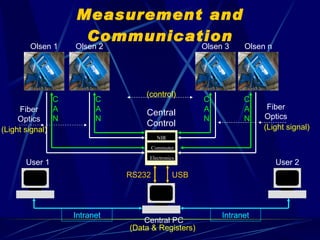

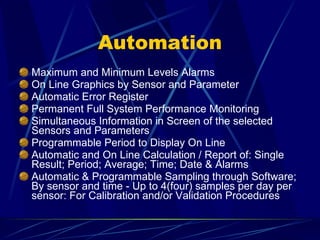

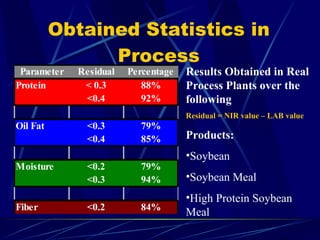

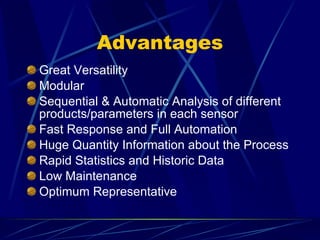

This document summarizes an online spectroscopy control system that uses fiber optic sensors for non-invasive measurement of liquids and solids. The system uses miniature CCD detection technology and no-moving optics for stable, chemical-free operation. It features customizable software, remote internet/intranet access, and the ability to automatically monitor and control up to 8 sensors simultaneously for fast, versatile analysis of industrial processes.