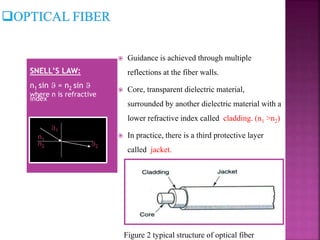

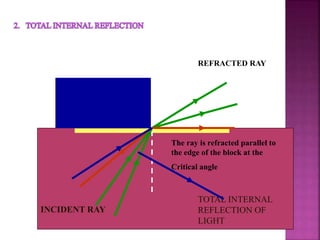

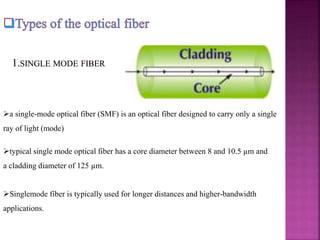

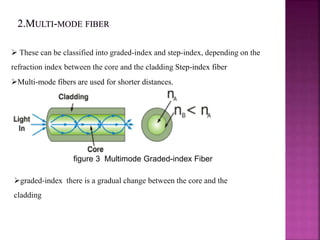

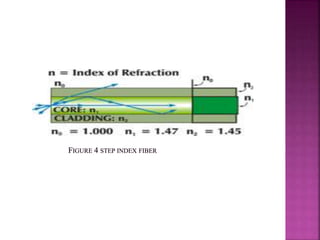

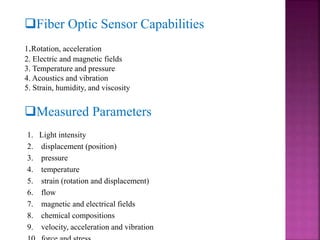

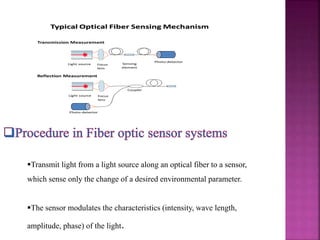

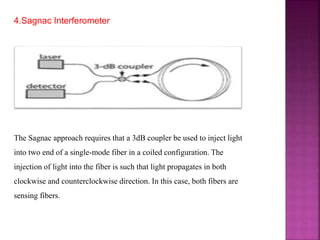

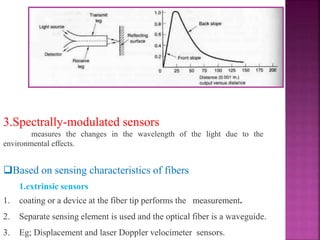

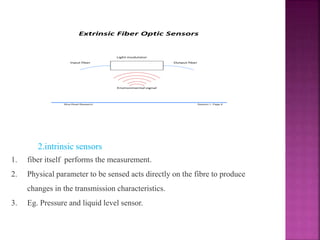

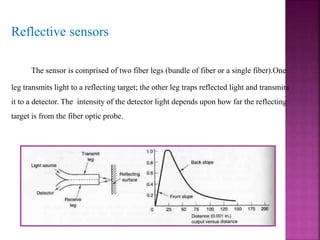

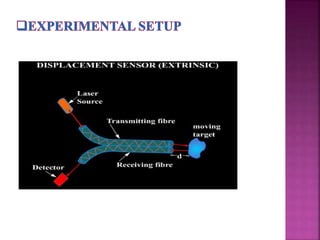

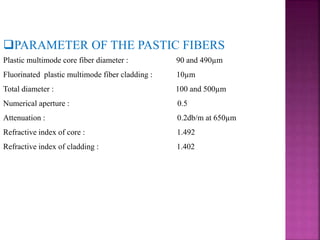

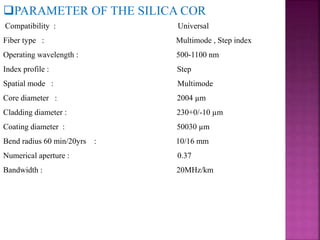

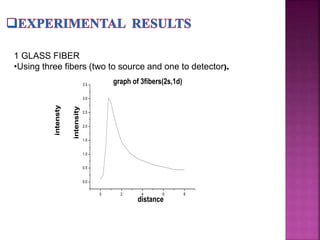

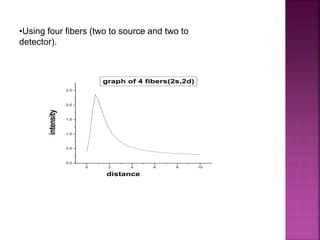

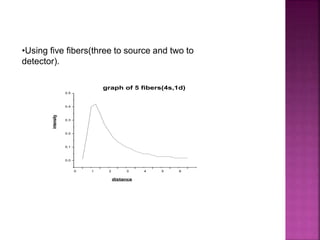

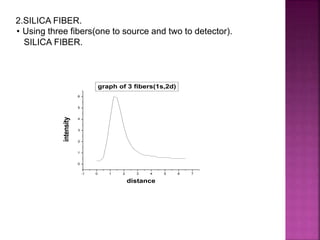

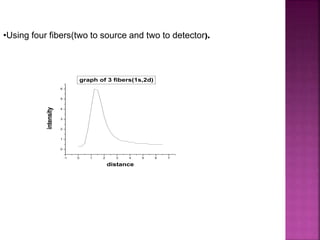

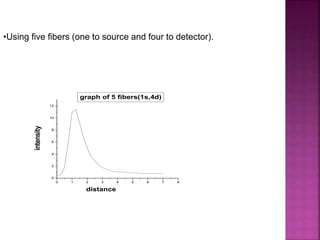

This document discusses optical fibers and fiber optic sensors. It begins with an introduction to optical fibers, including their principles, types, advantages and disadvantages. It then discusses fiber optic sensors, including their components, classifications, and uses. It focuses on displacement sensors, explaining their principles, experimental setup, results and applications. Displacement sensors can be designed using glass or plastic optical fibers with different numbers of fibers, and their sensitivity depends on the fiber material and number of fibers used.