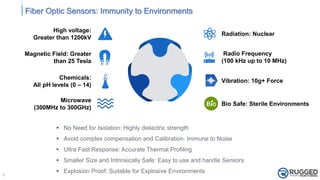

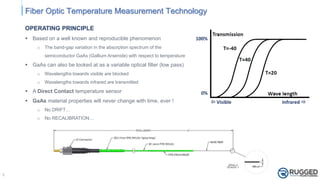

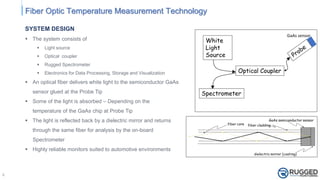

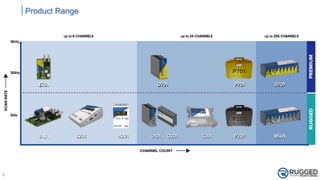

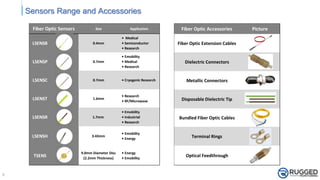

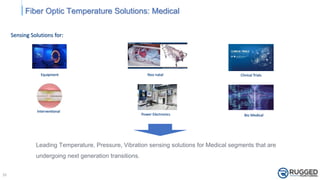

Rugged Monitoring designs, manufactures, and commercializes rugged fiber optic temperature sensors and monitors for various applications including laboratories, utilities, industrial processes, medical, and OEM uses. It aims to be the leading provider of fiber optic-based sensing solutions through offering reliable, high-performance, precise, and customizable sensors and monitoring solutions. The company's products include fiber optic sensors, monitors, accessories, and software.