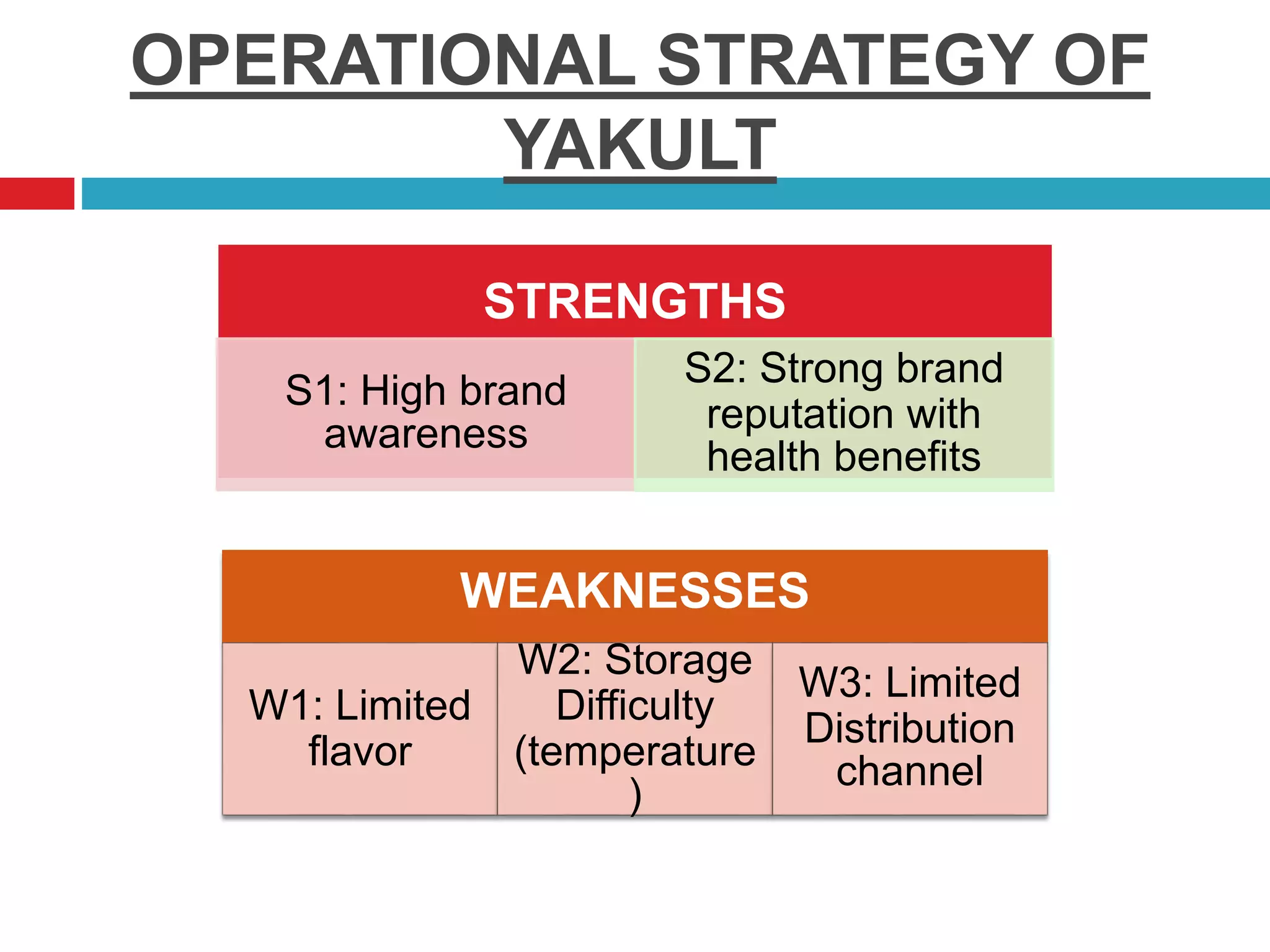

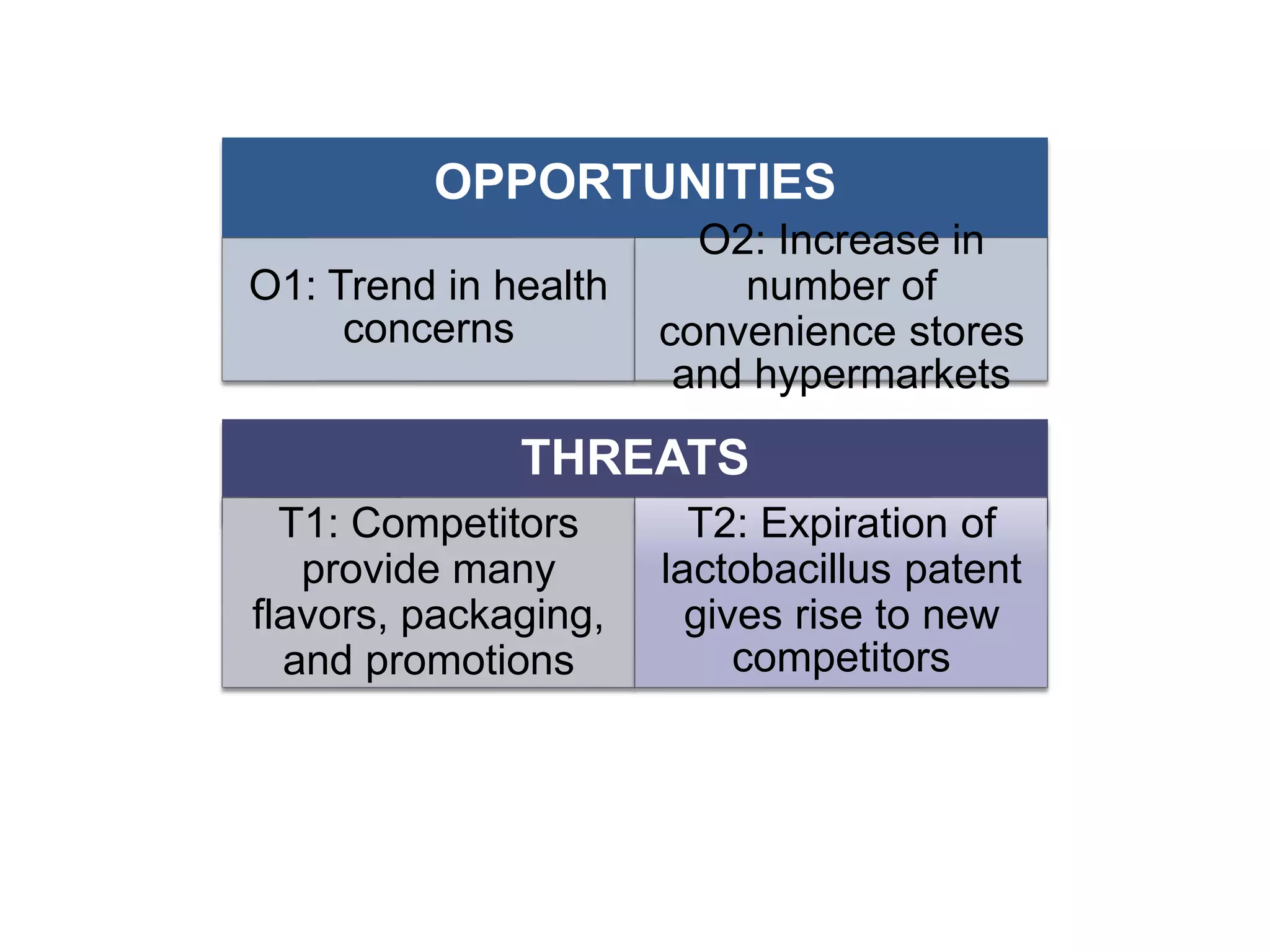

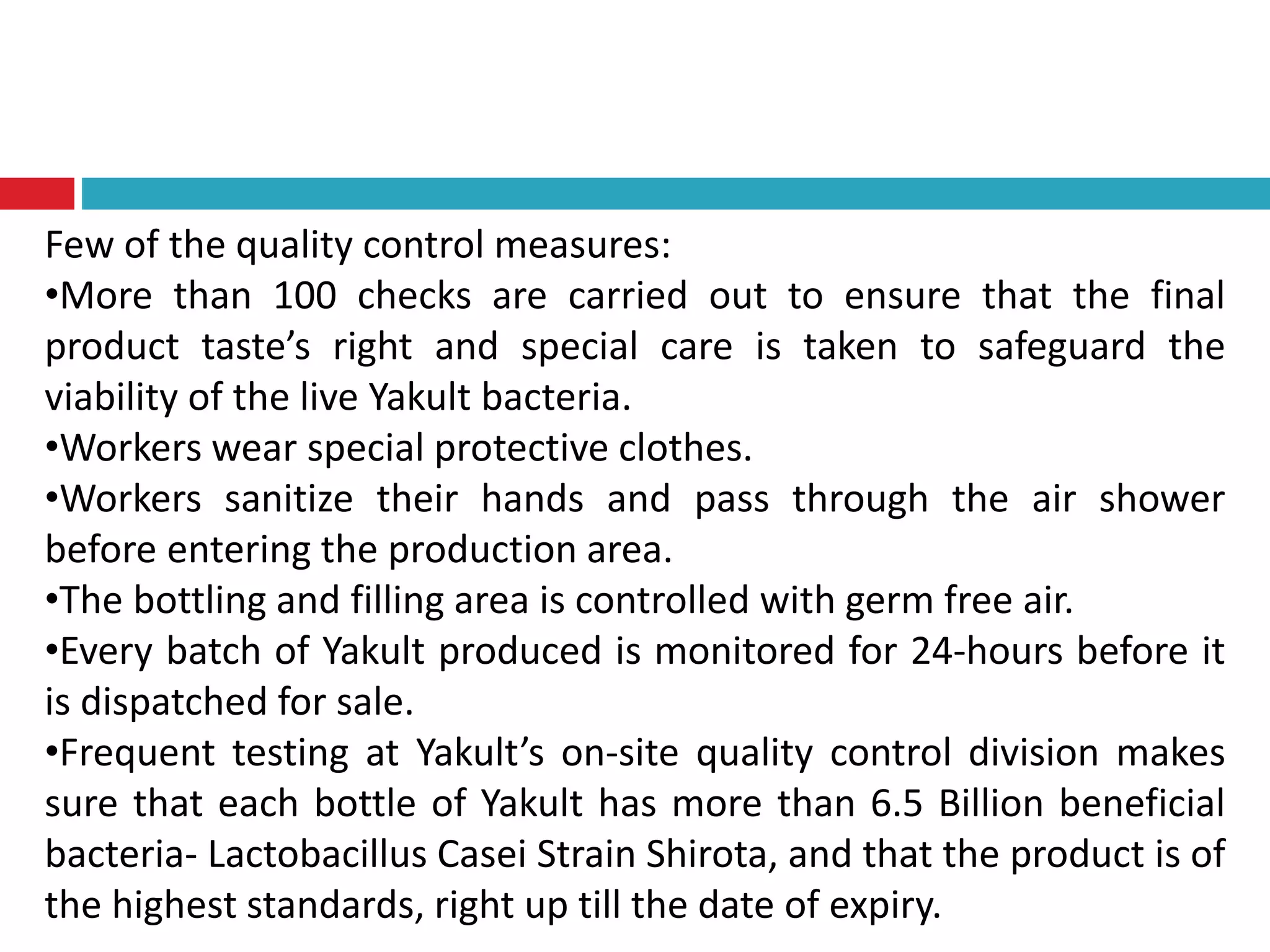

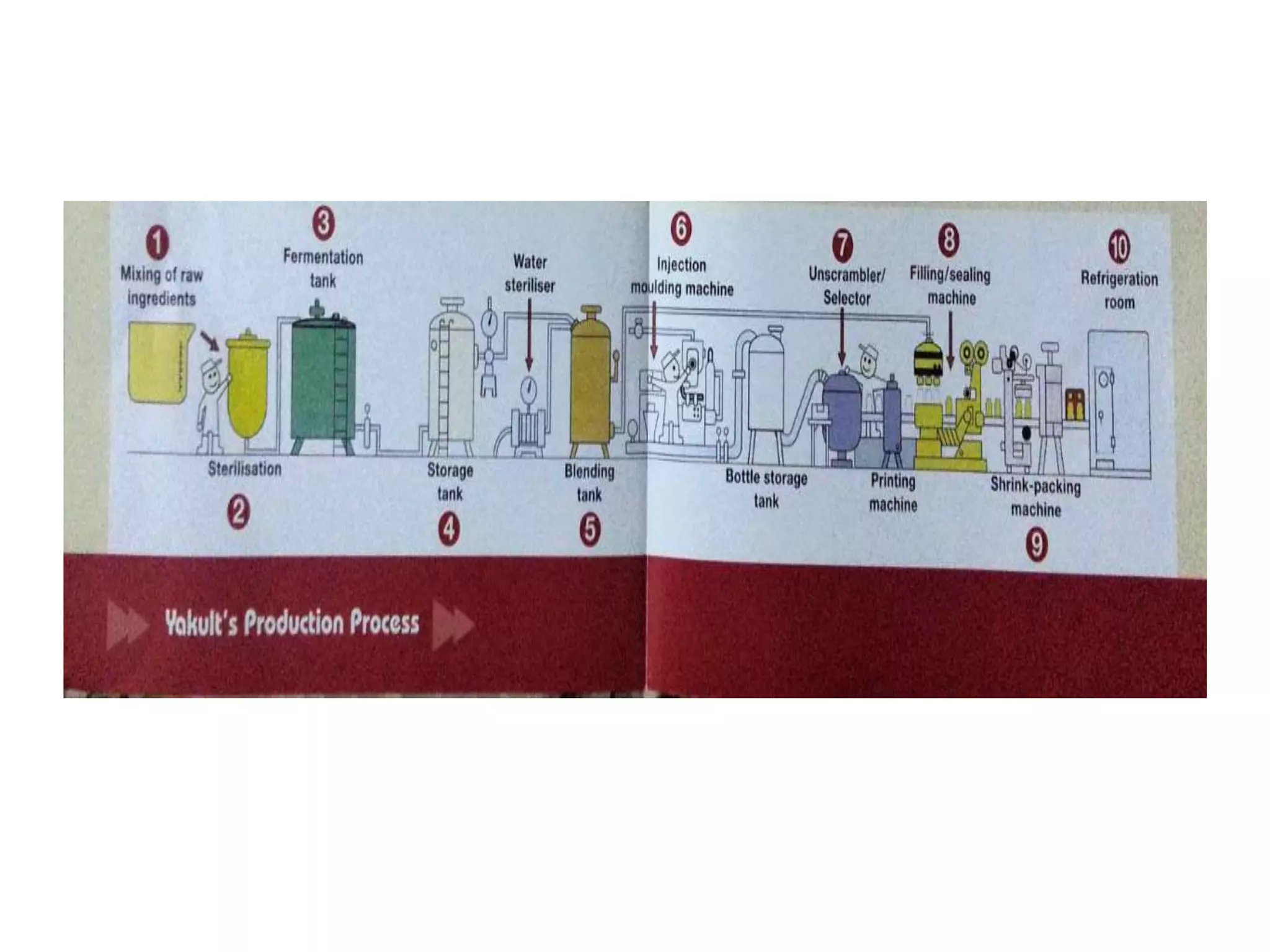

This document summarizes Yakult Danone India, a joint venture between Yakult Honsha of Japan and Groupe Danone of France formed in 2005. It manufactures and sells probiotic products in India, launching the probiotic drink Yakult in 2007 which is now available in several major Indian cities. The company aims to build awareness of probiotics and contribute to public health. Key aspects covered include quality control measures to ensure product safety and viability of live bacteria cultures in Yakult.