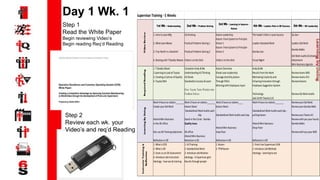

The document outlines a 5-week training program for new area managers to develop their leadership skills in an Operations Excellence (OE) environment. The training focuses on critical middle management roles and translating the company's vision into action. Each week covers a different topic such as problem solving, continuous improvement, and leadership. Trainees are required to complete readings, review videos, and do hands-on learning activities like gemba walks, standardized work audits, and developing their own standardized work. At the end of each week, trainees reflect on their lessons and discuss the material in class. The goal is for managers to truly understand and live the OE approach from the ground up.