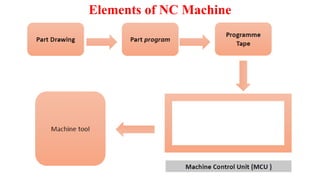

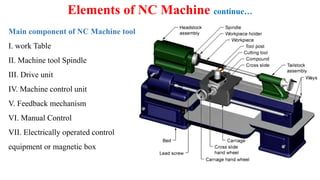

Numerically controlled (NC) machine tools are controlled by programmed instructions rather than a human operator. The NC program contains a set of instructions that control machine functions like spindle speed, tool positioning, and feed rate. Key components of an NC machine include the part program, program tape, machine control unit, machine tool, and feedback mechanism. The MCU reads and interprets the part program to automate the machine tool's motions and functions. NC machines enable high accuracy, reduced setup times, and increased productivity compared to conventional machine tools.