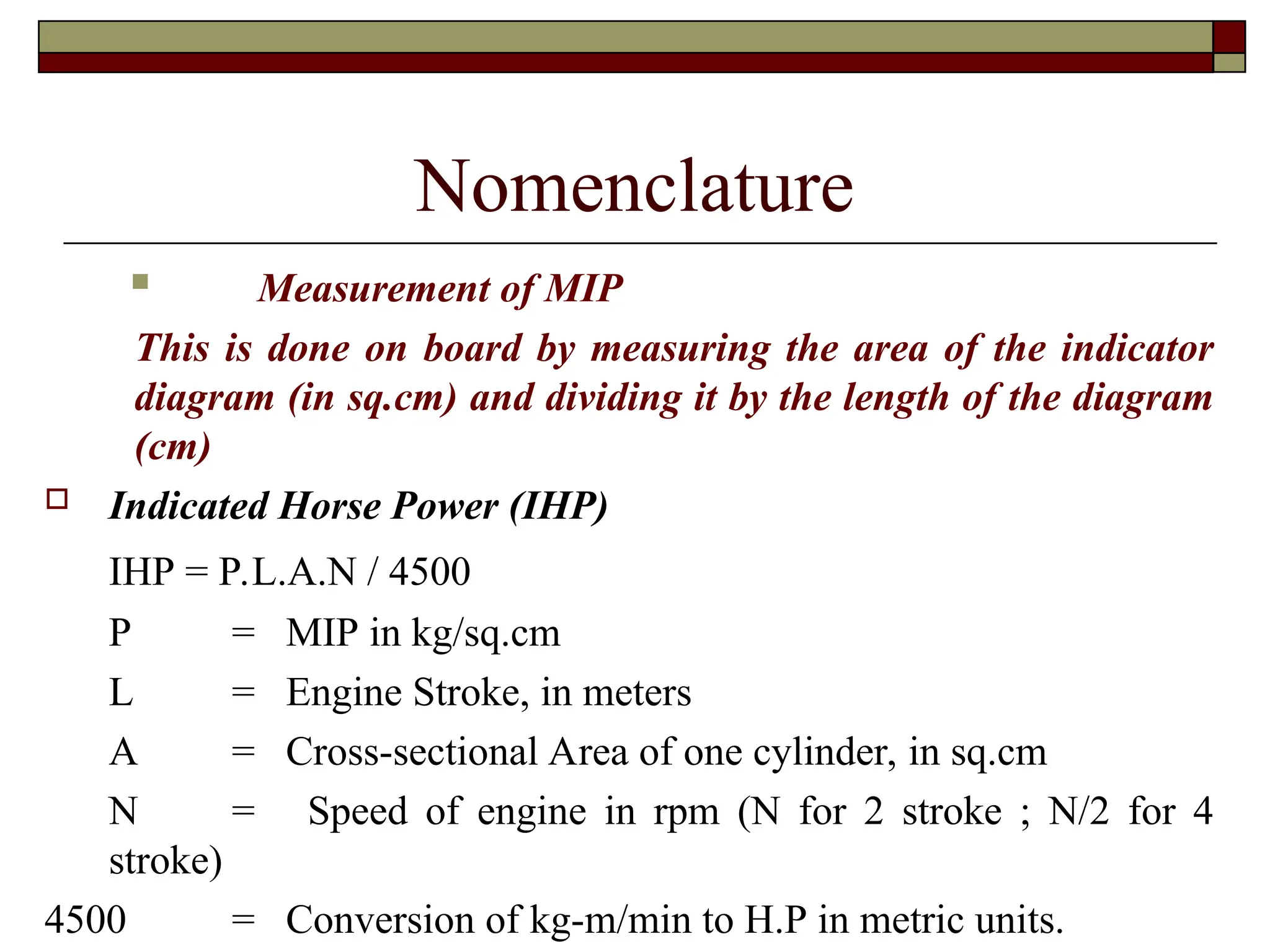

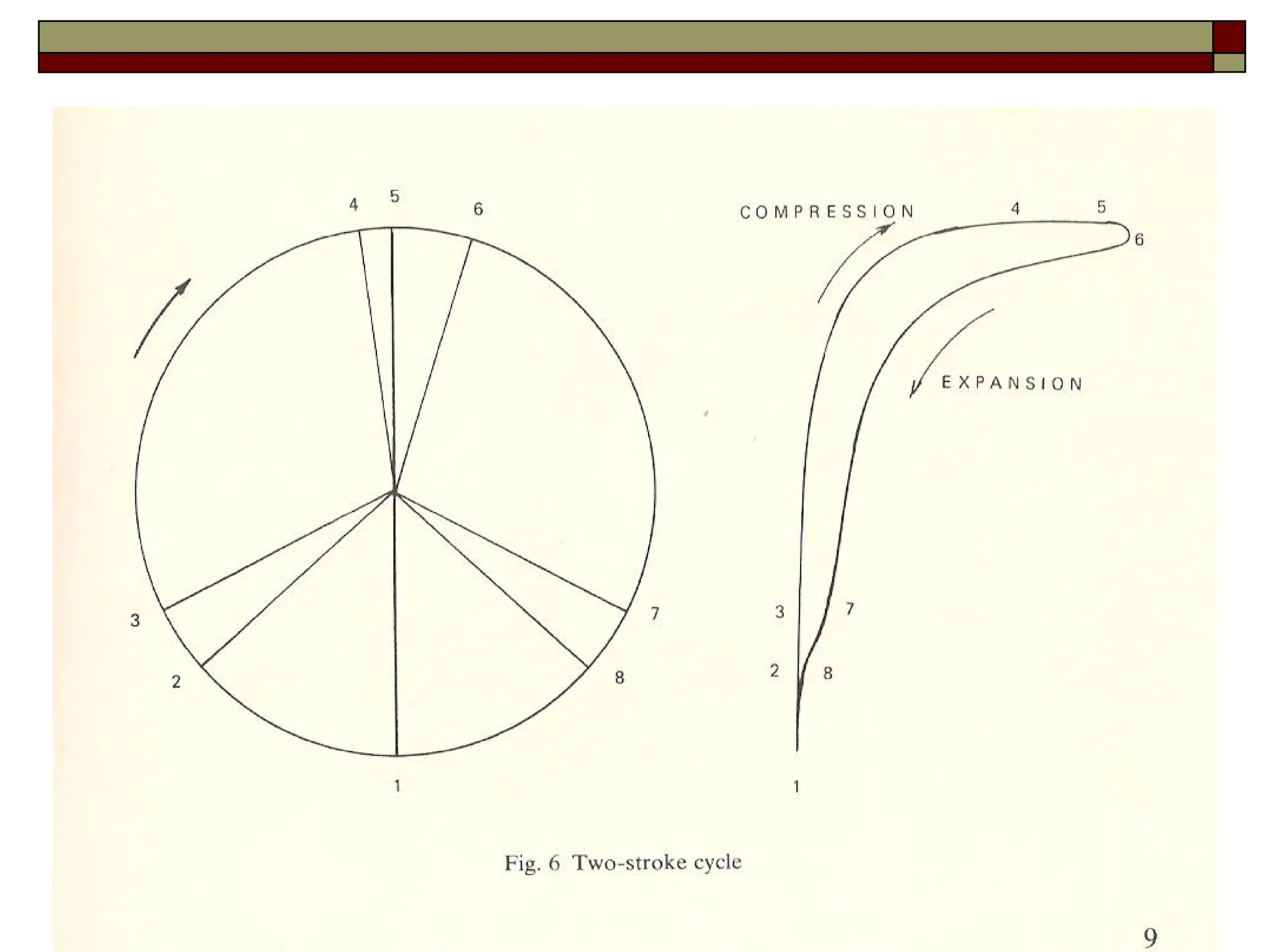

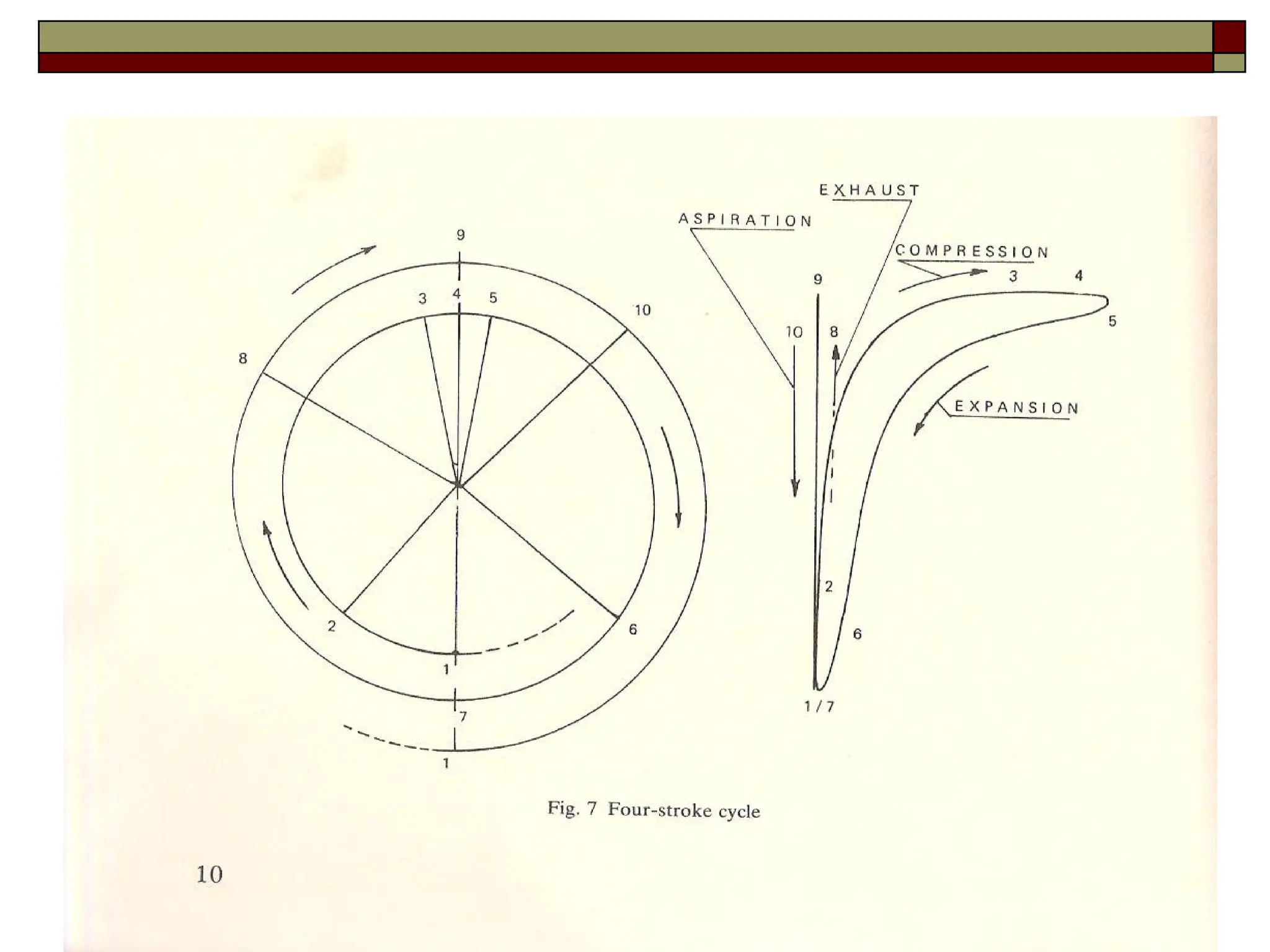

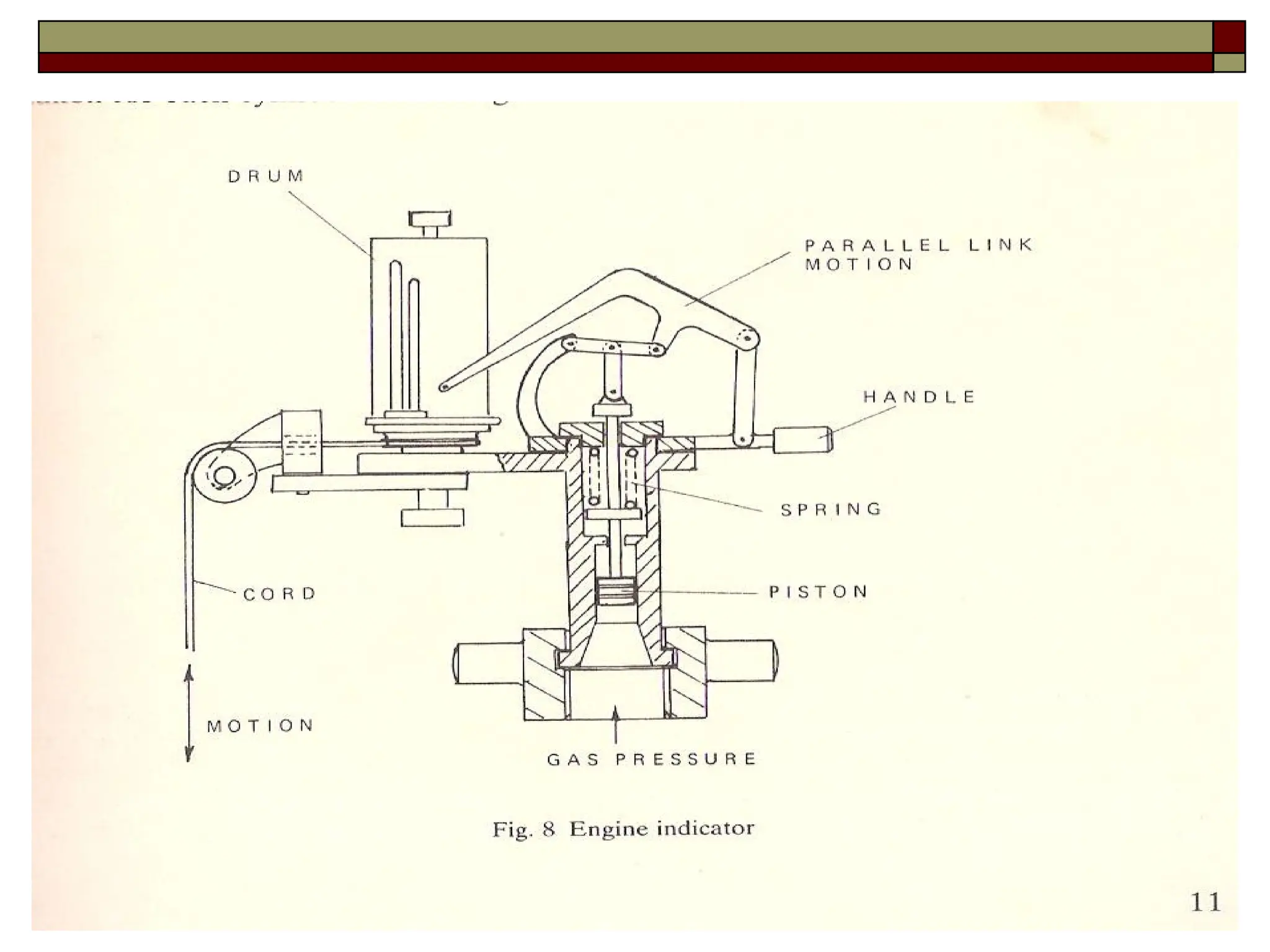

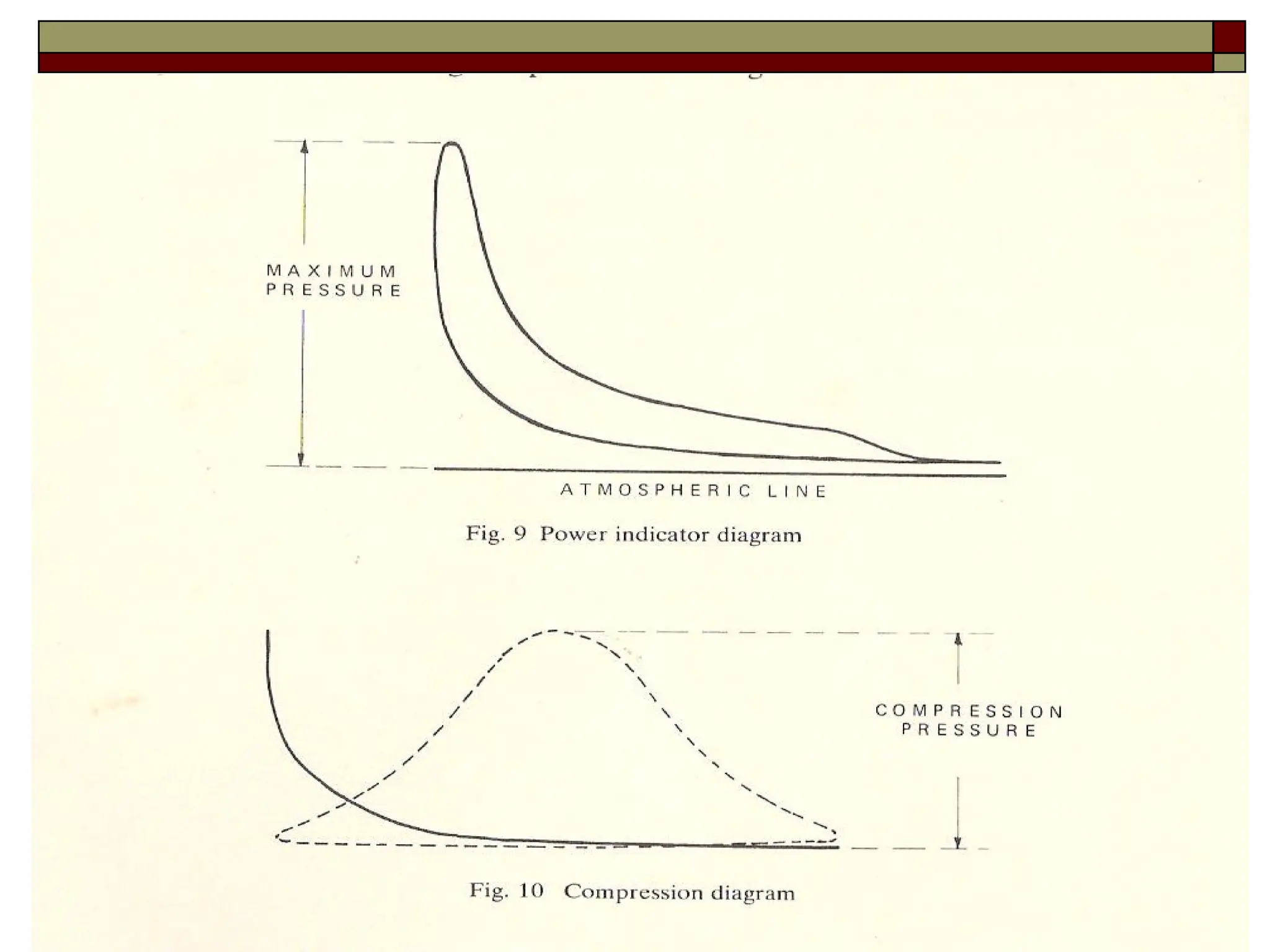

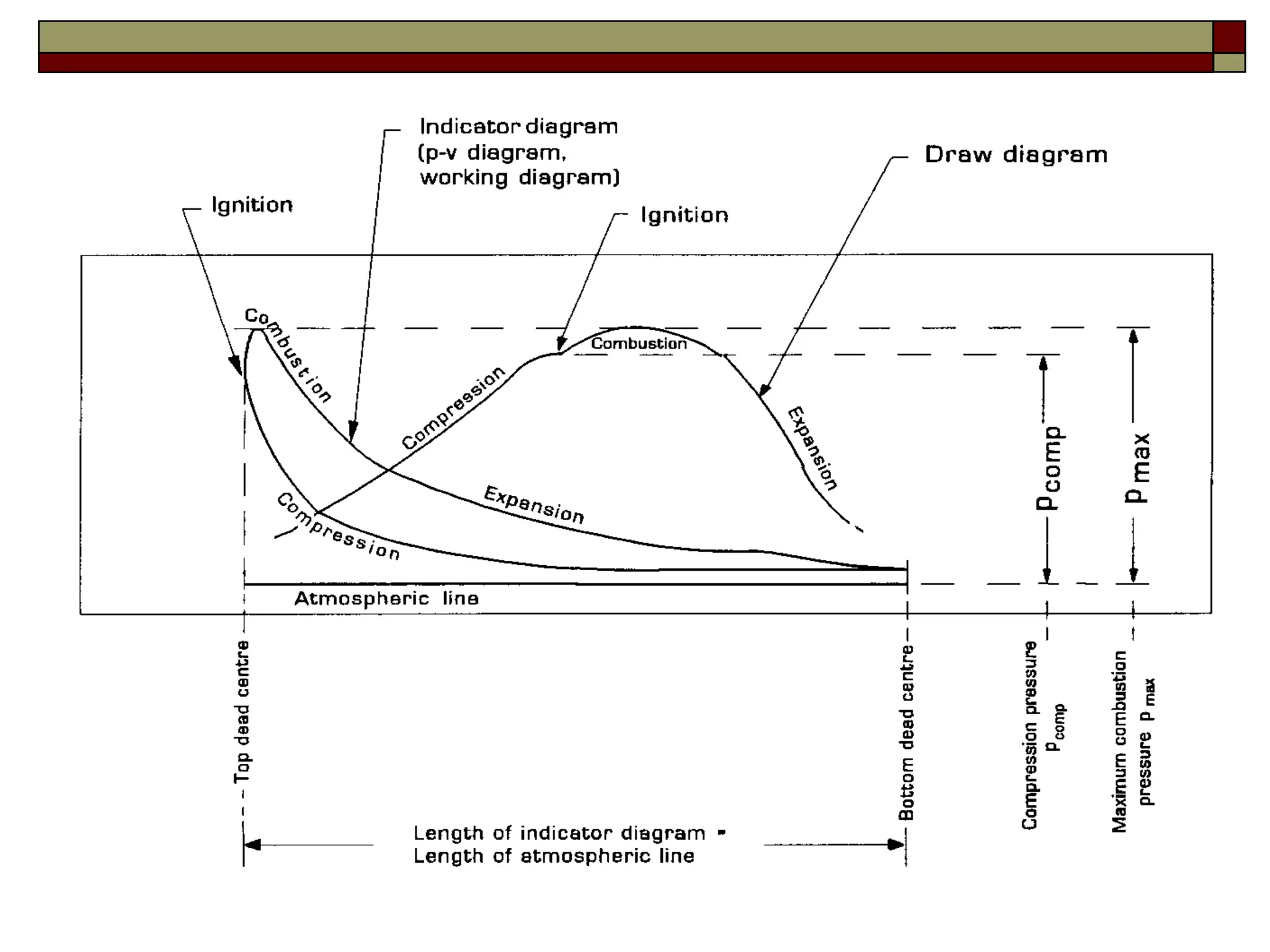

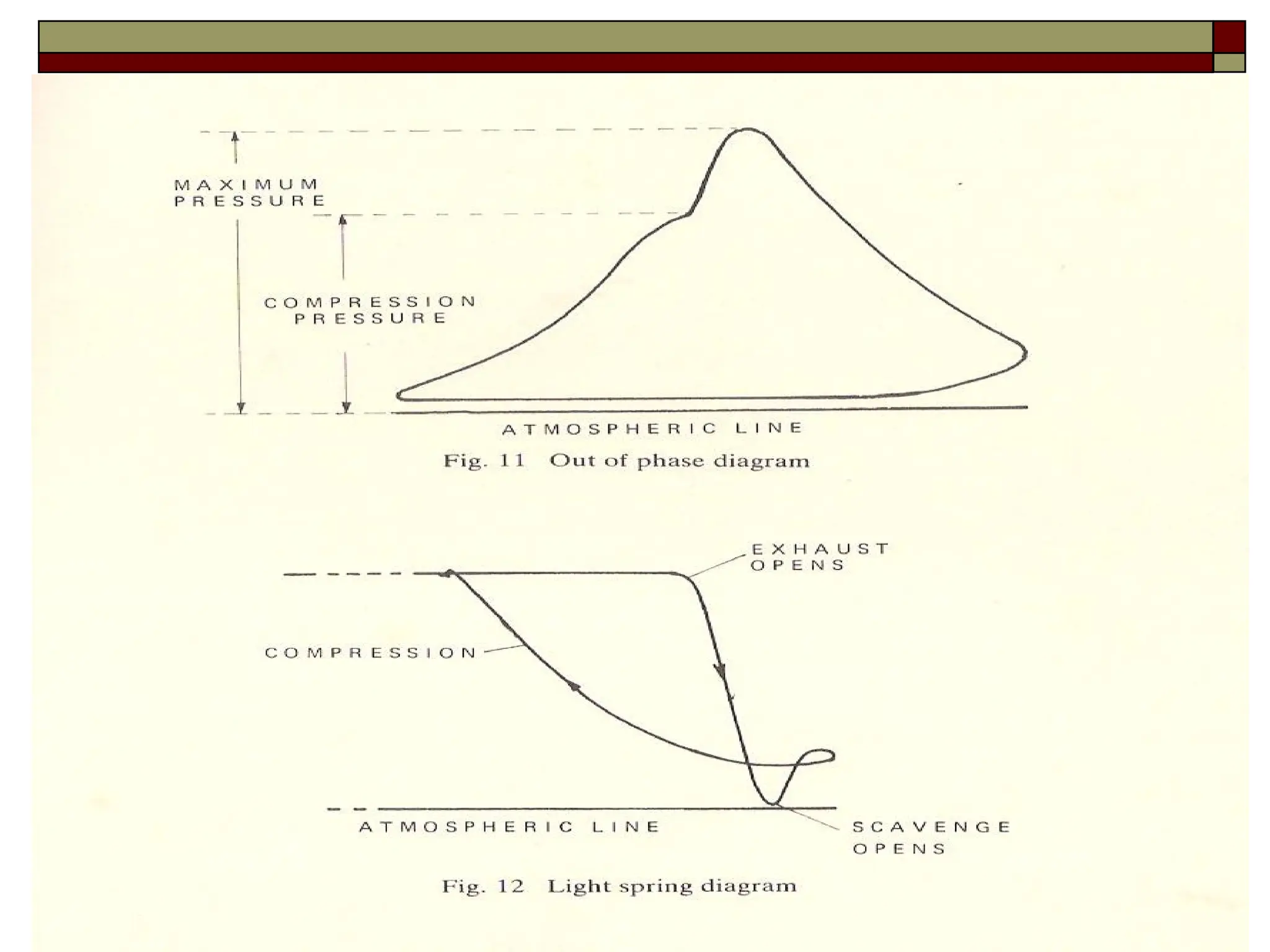

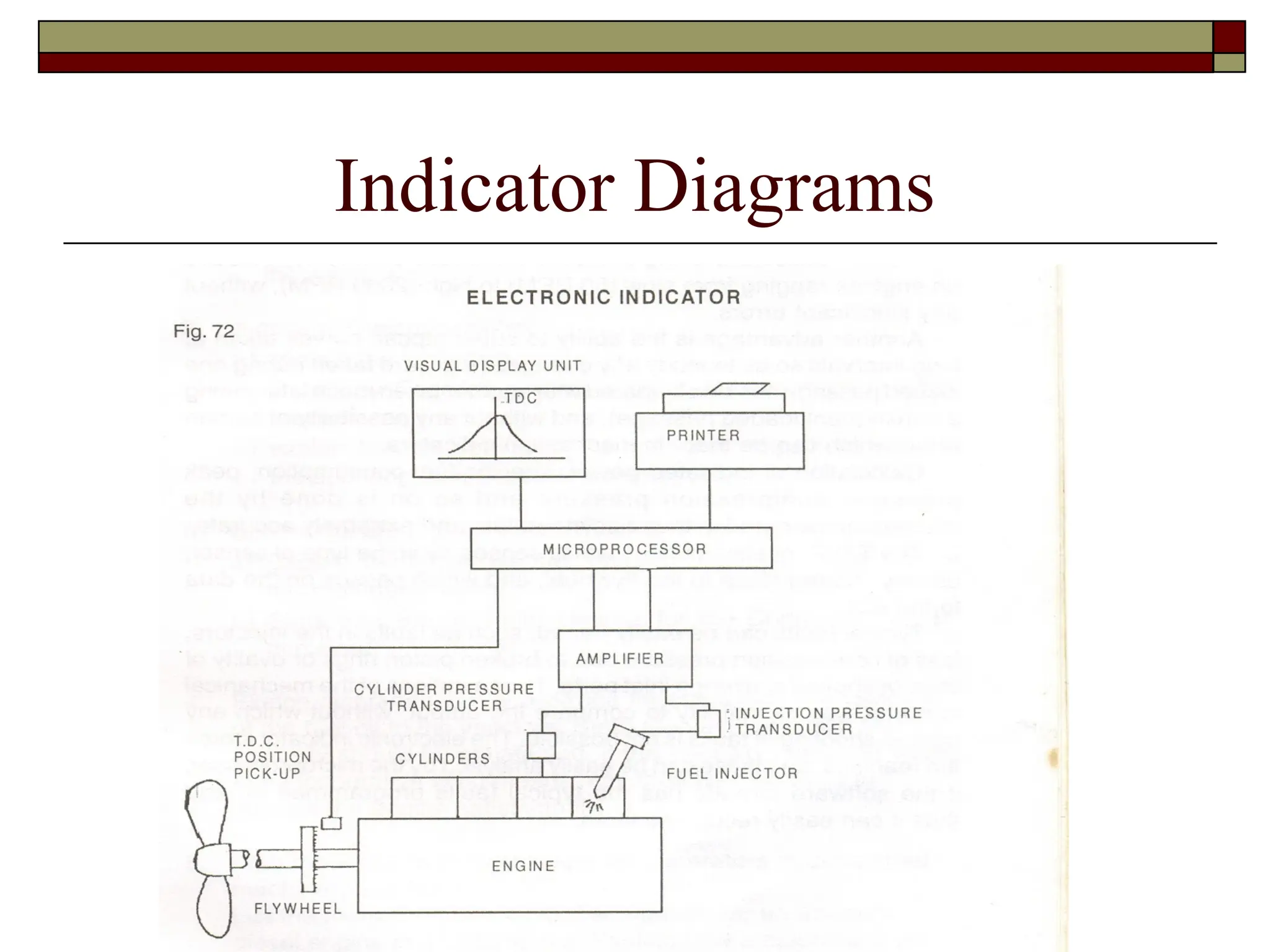

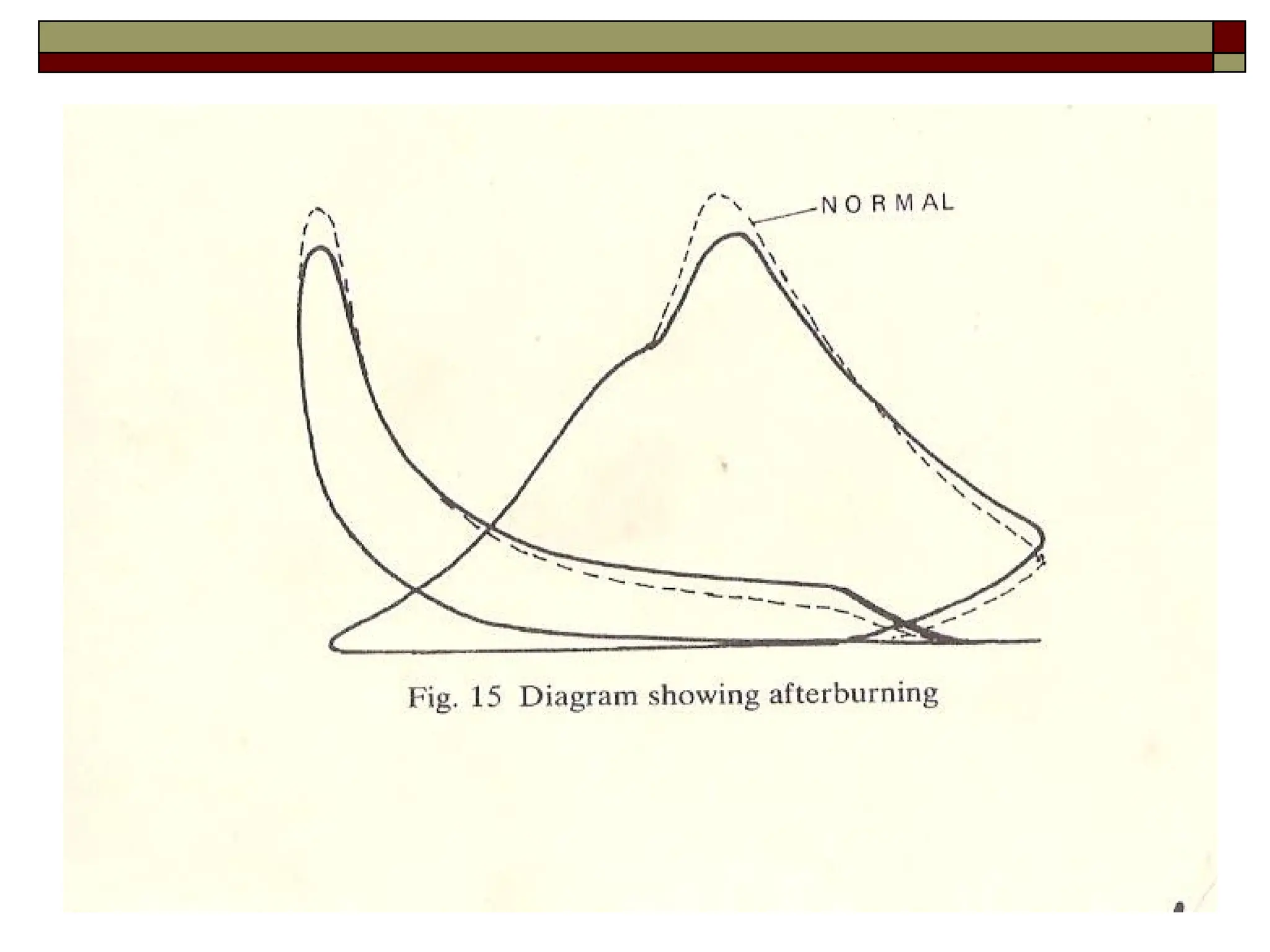

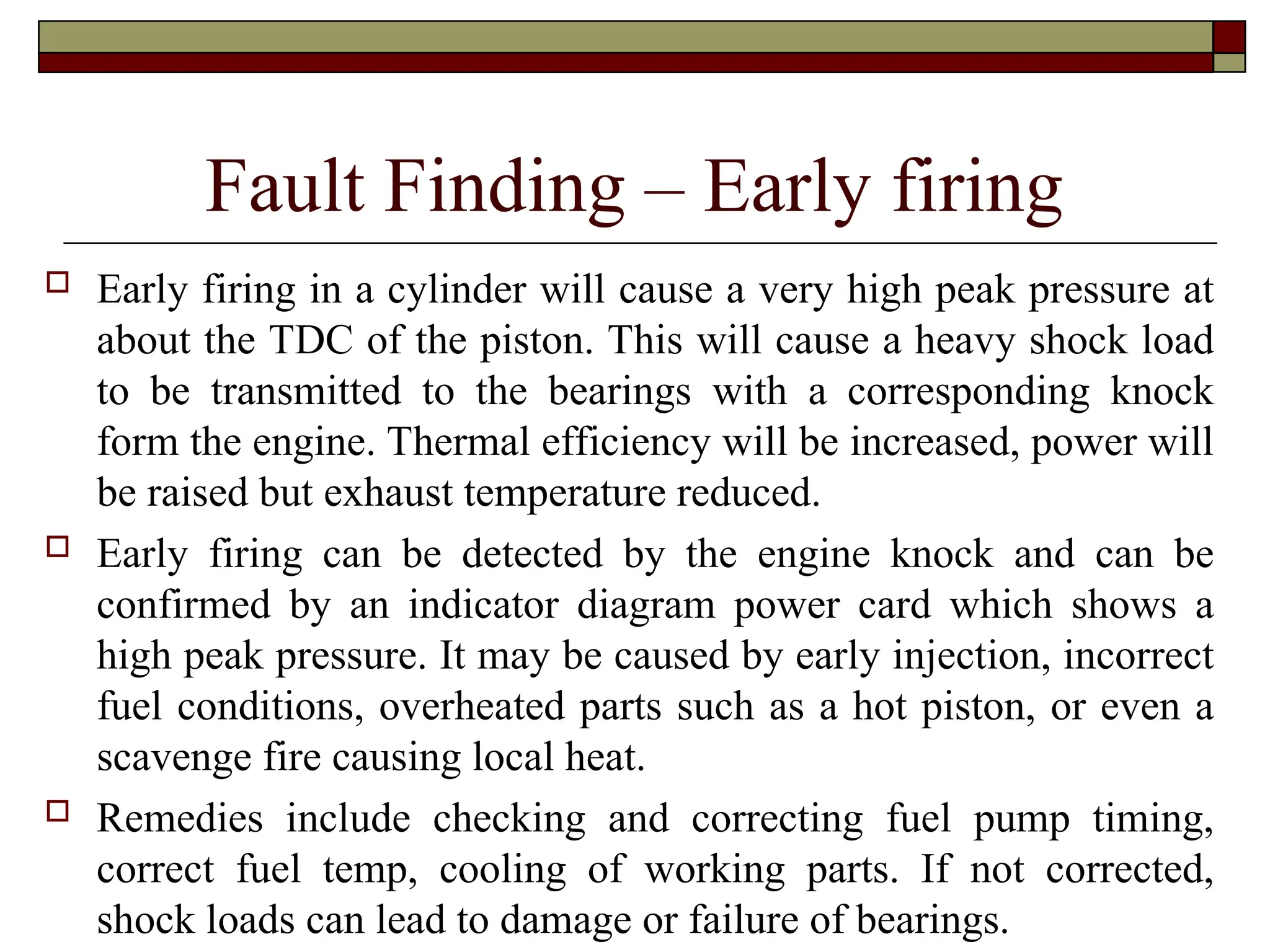

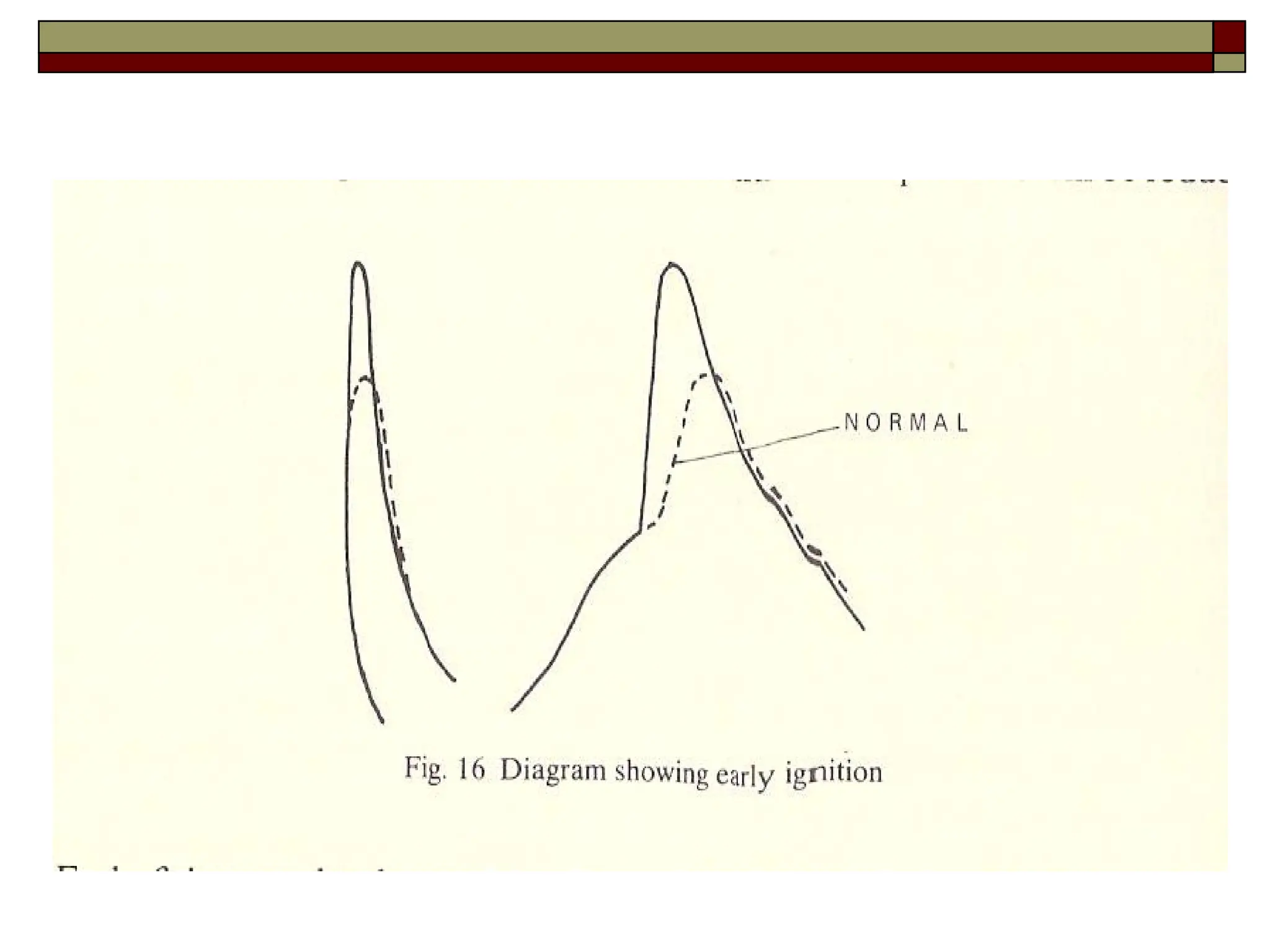

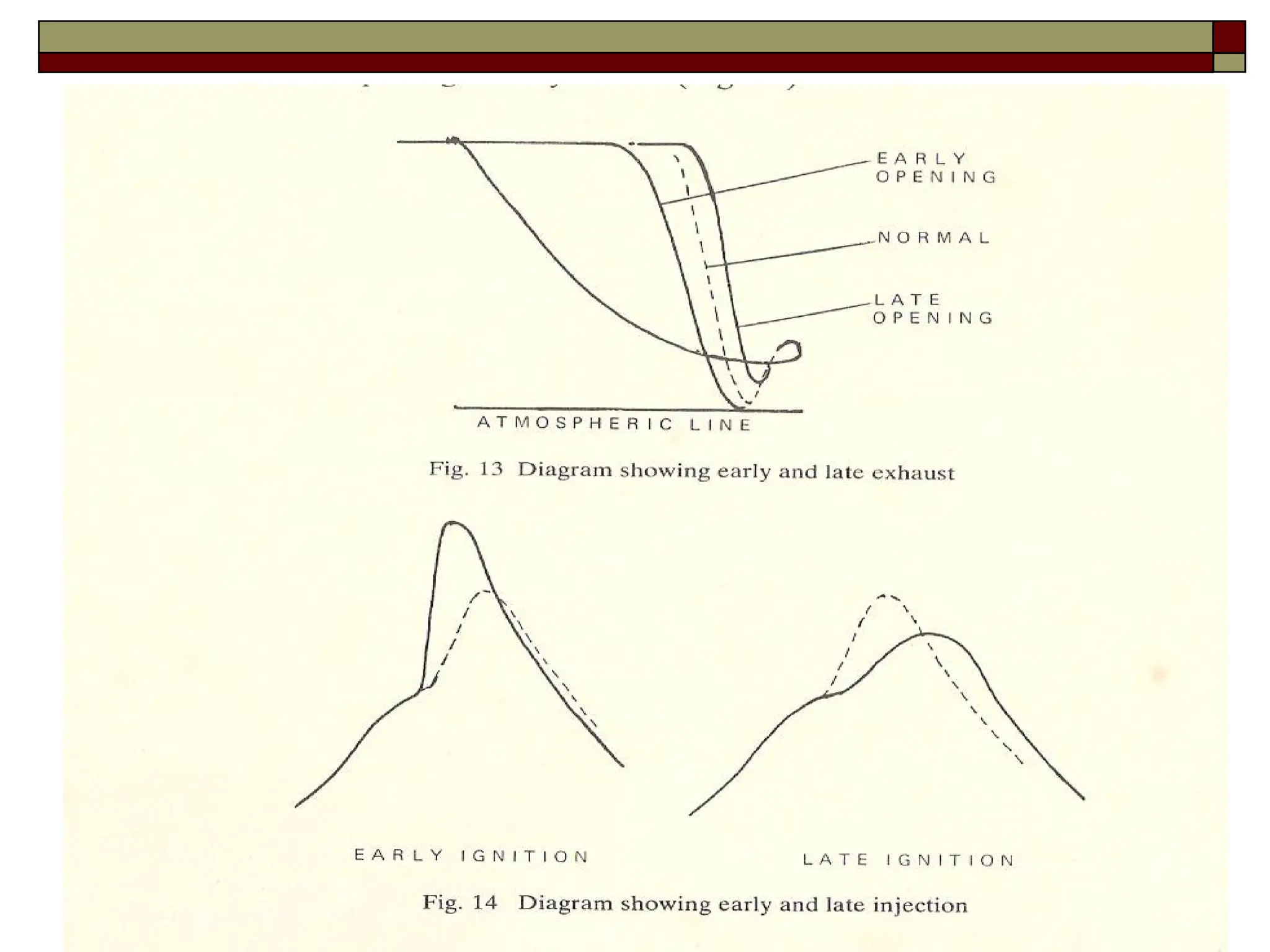

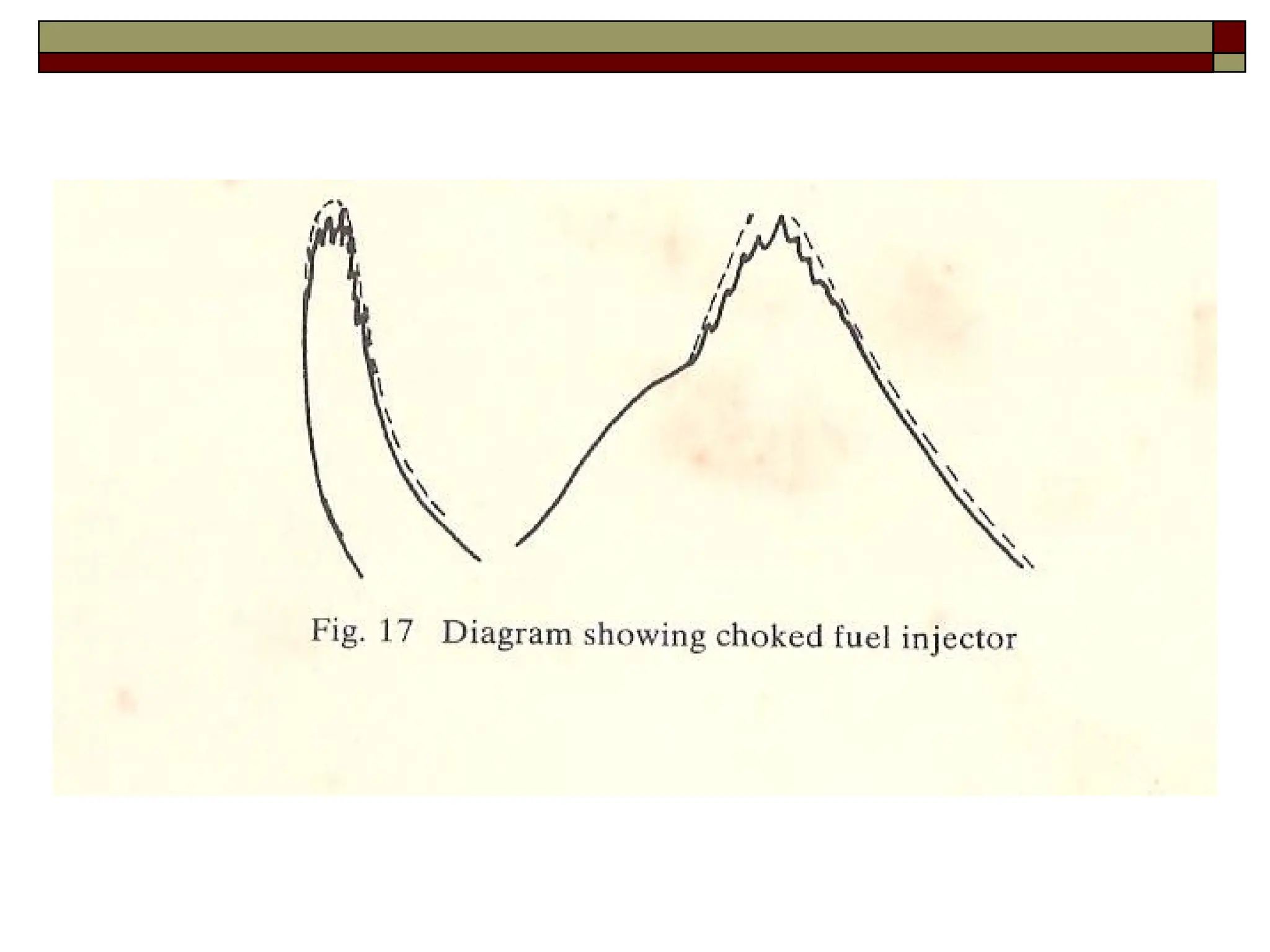

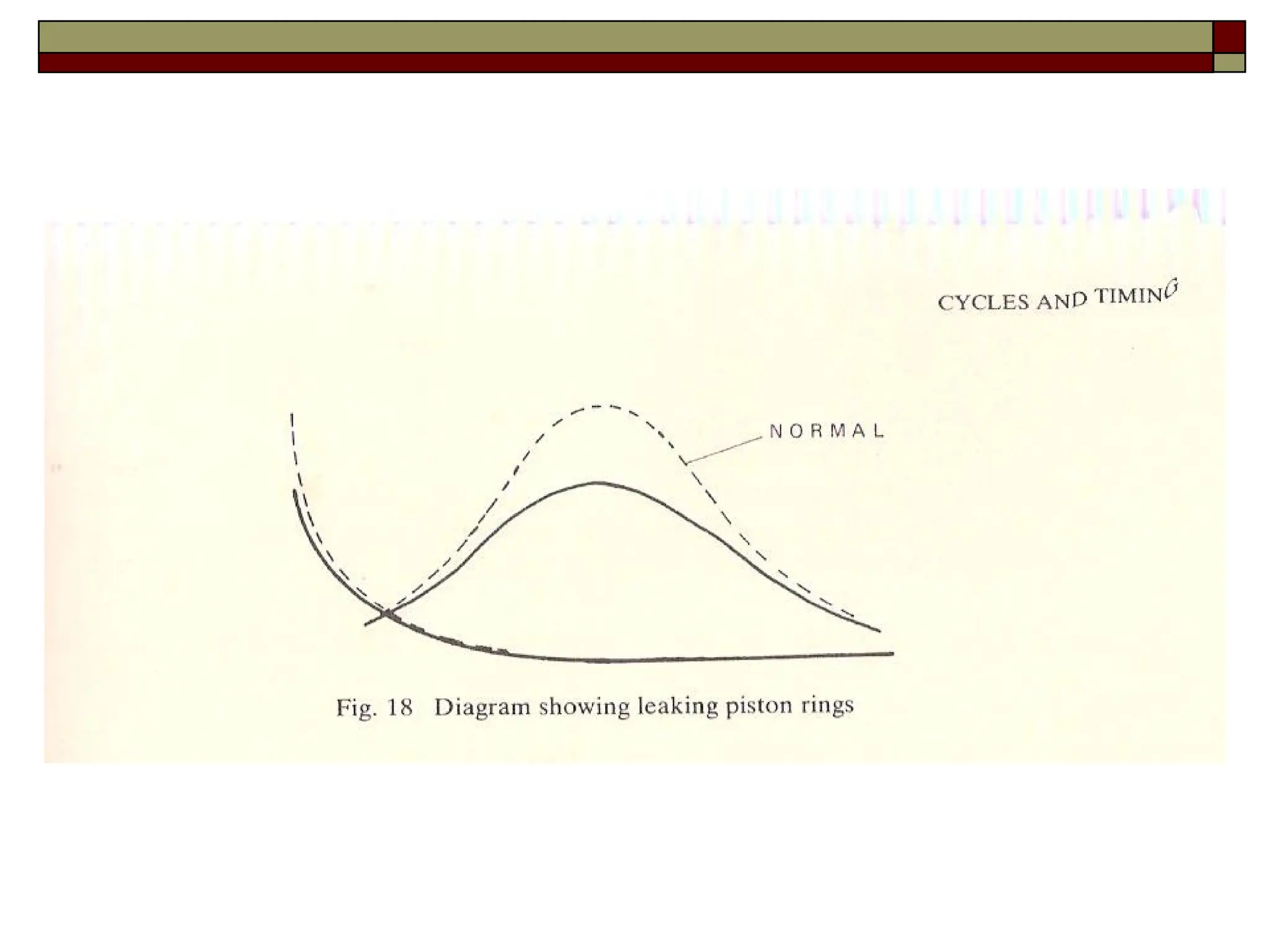

The document provides a comprehensive overview of power measurement in marine engines, explaining key concepts such as mean effective pressure (mep), indicated horsepower (ihp), brake horsepower (bhp), and efficiency metrics. It details the procedures for conducting test-bed and sea trials, as well as the importance of indicator diagrams in diagnosing engine conditions and performance. The document also discusses fault detection and remedies for various issues such as afterburning, early firing, choked fuel valves, and leaky piston rings.