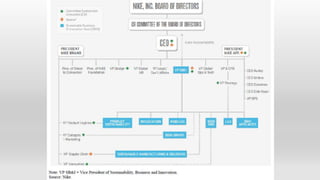

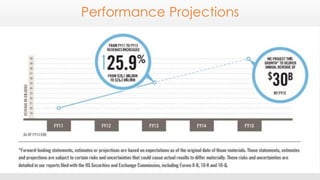

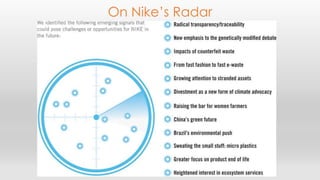

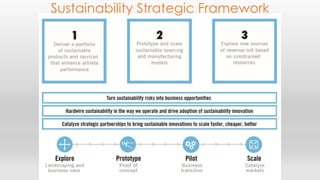

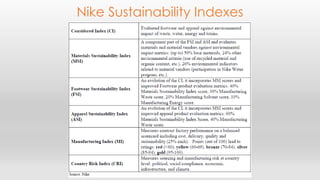

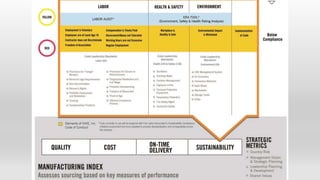

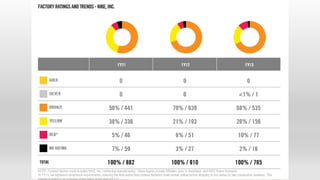

Nike has undergone a significant transformation over the past fifteen years, focusing on integrating sustainability into its business model and corporate structure. The company has shifted its corporate responsibility team towards addressing root causes of sustainability and labor issues while developing custom sustainability indexes to guide product development. Key initiatives include enhancing training for labor practices, promoting transparency in factory standards, and leveraging sustainability as a core component of product innovation and marketing.