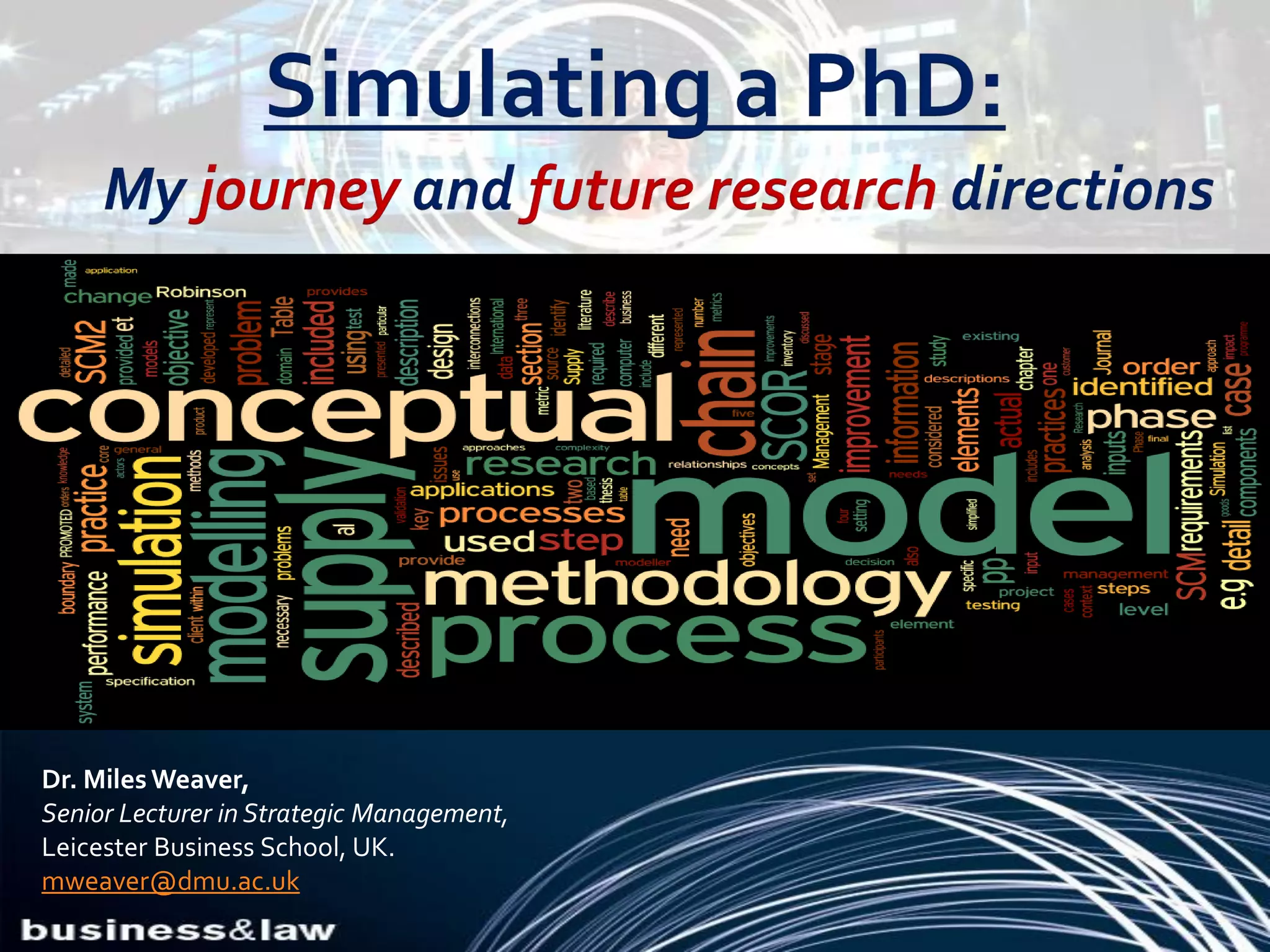

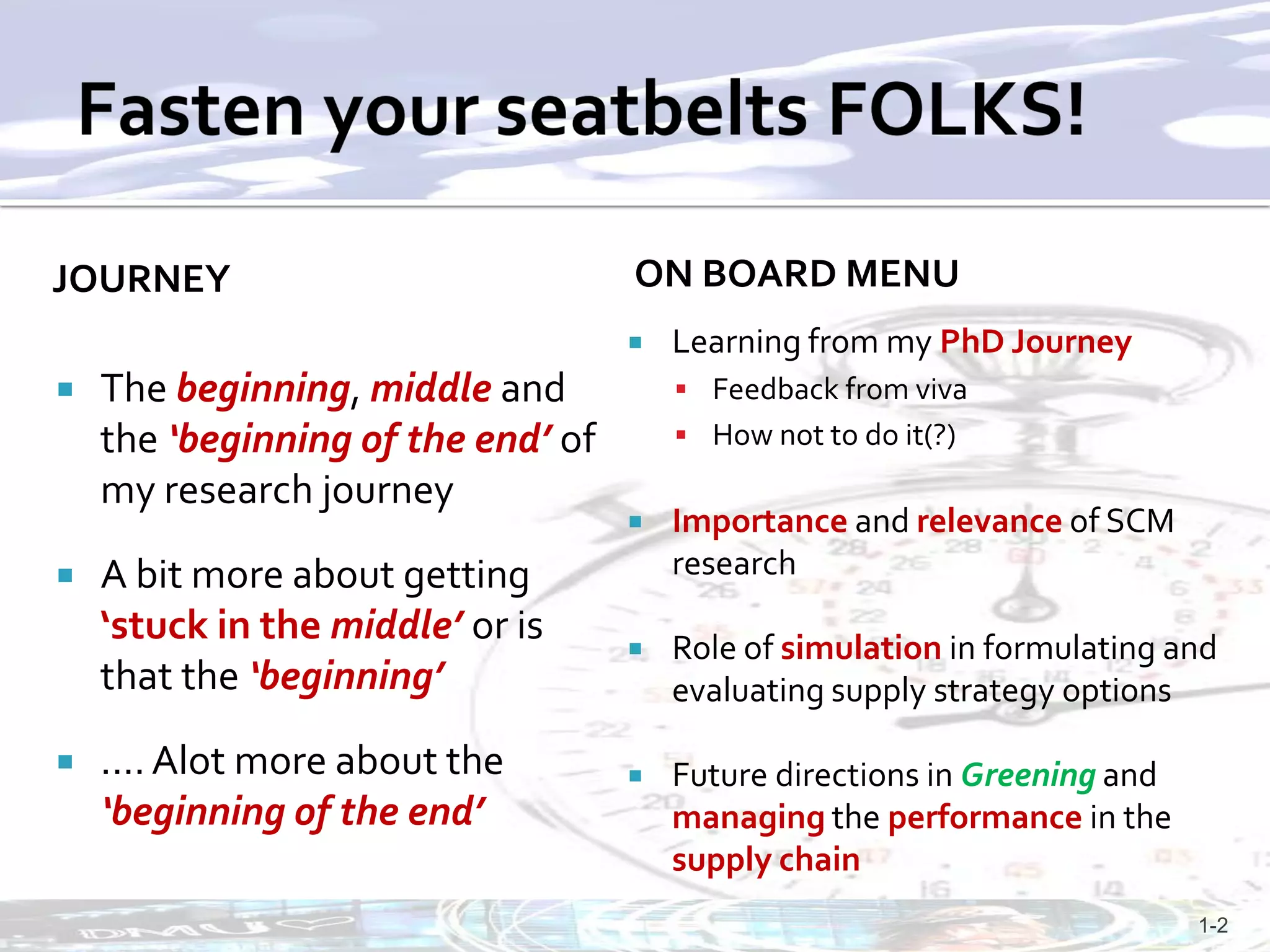

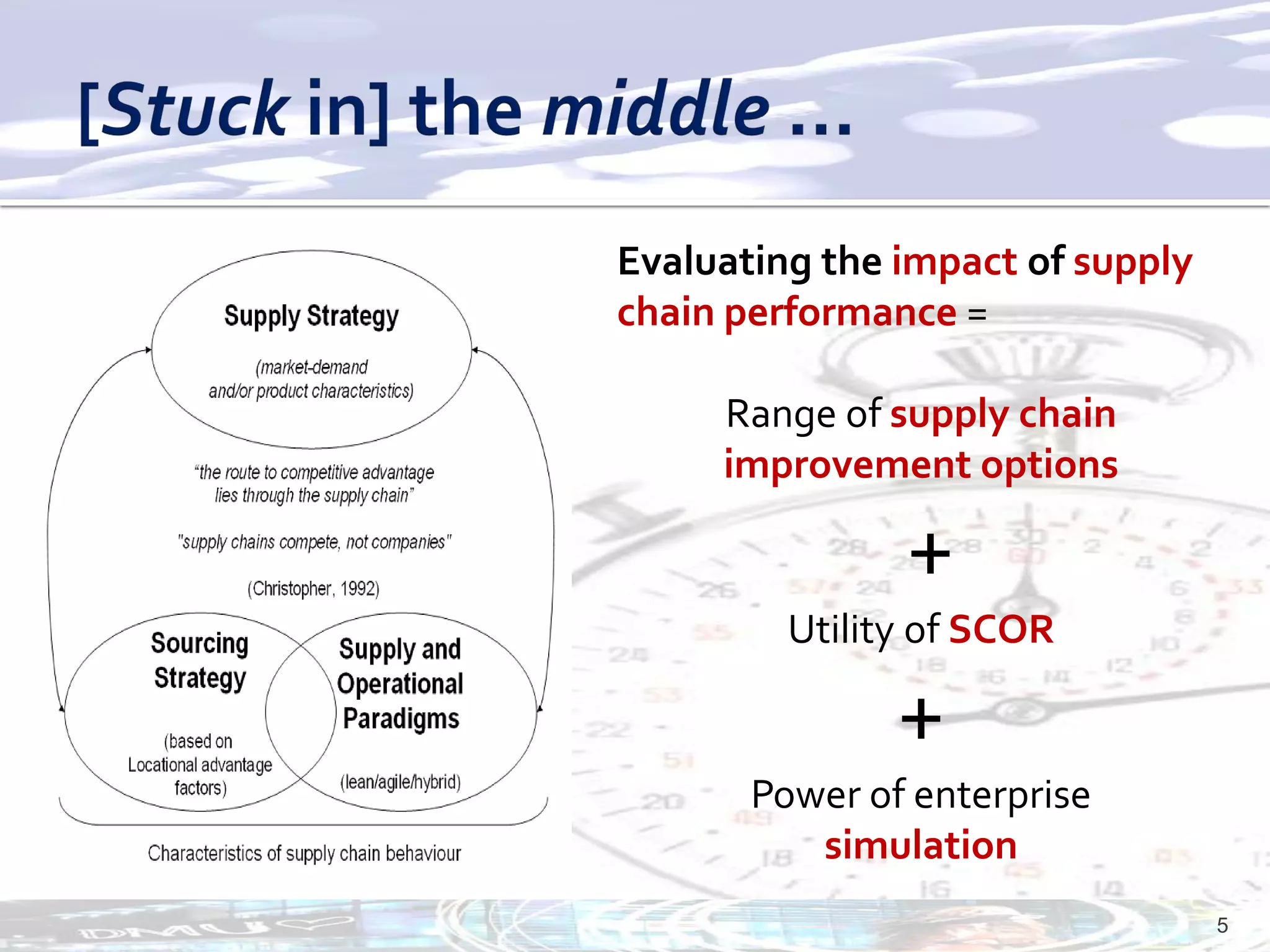

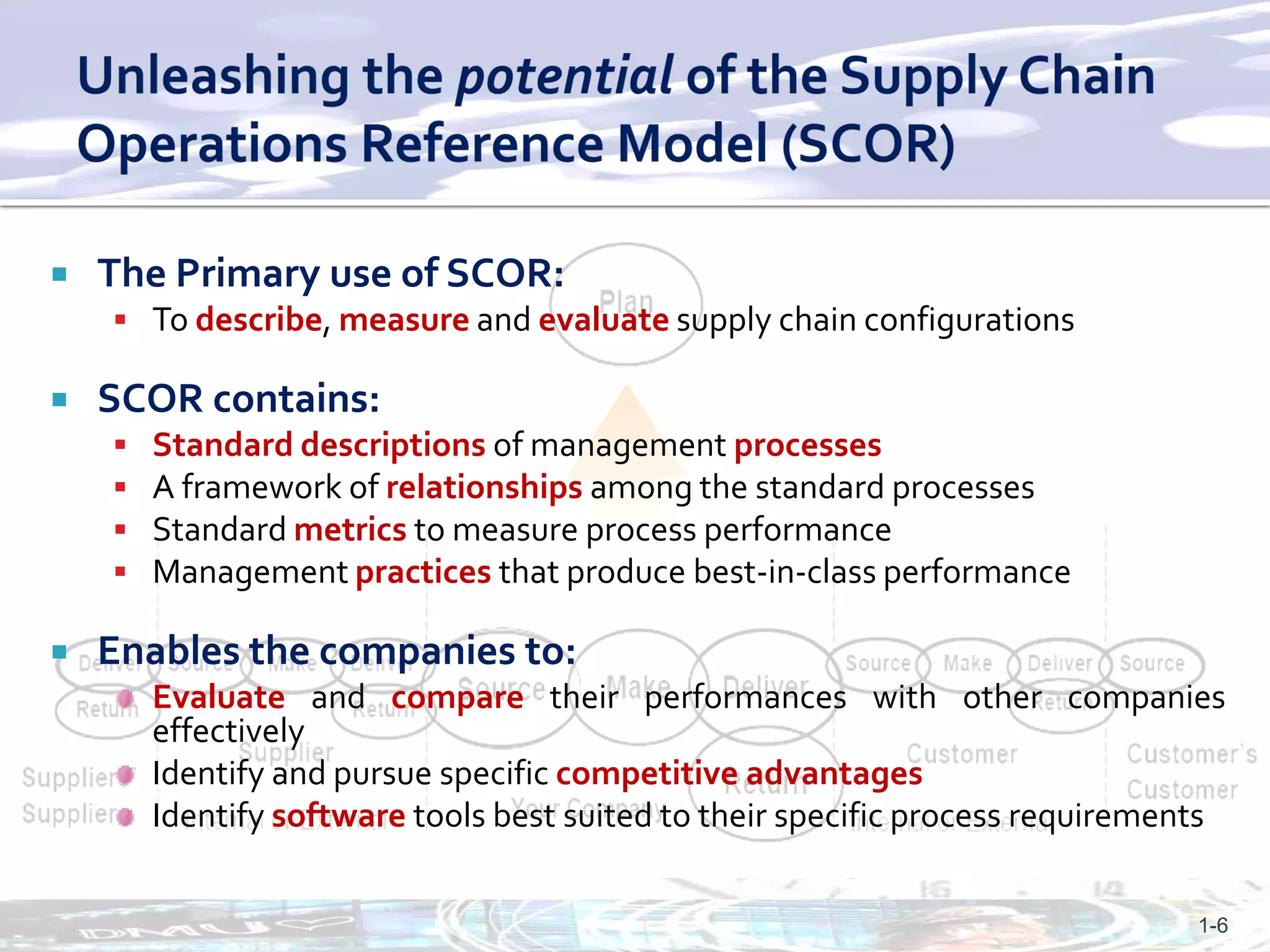

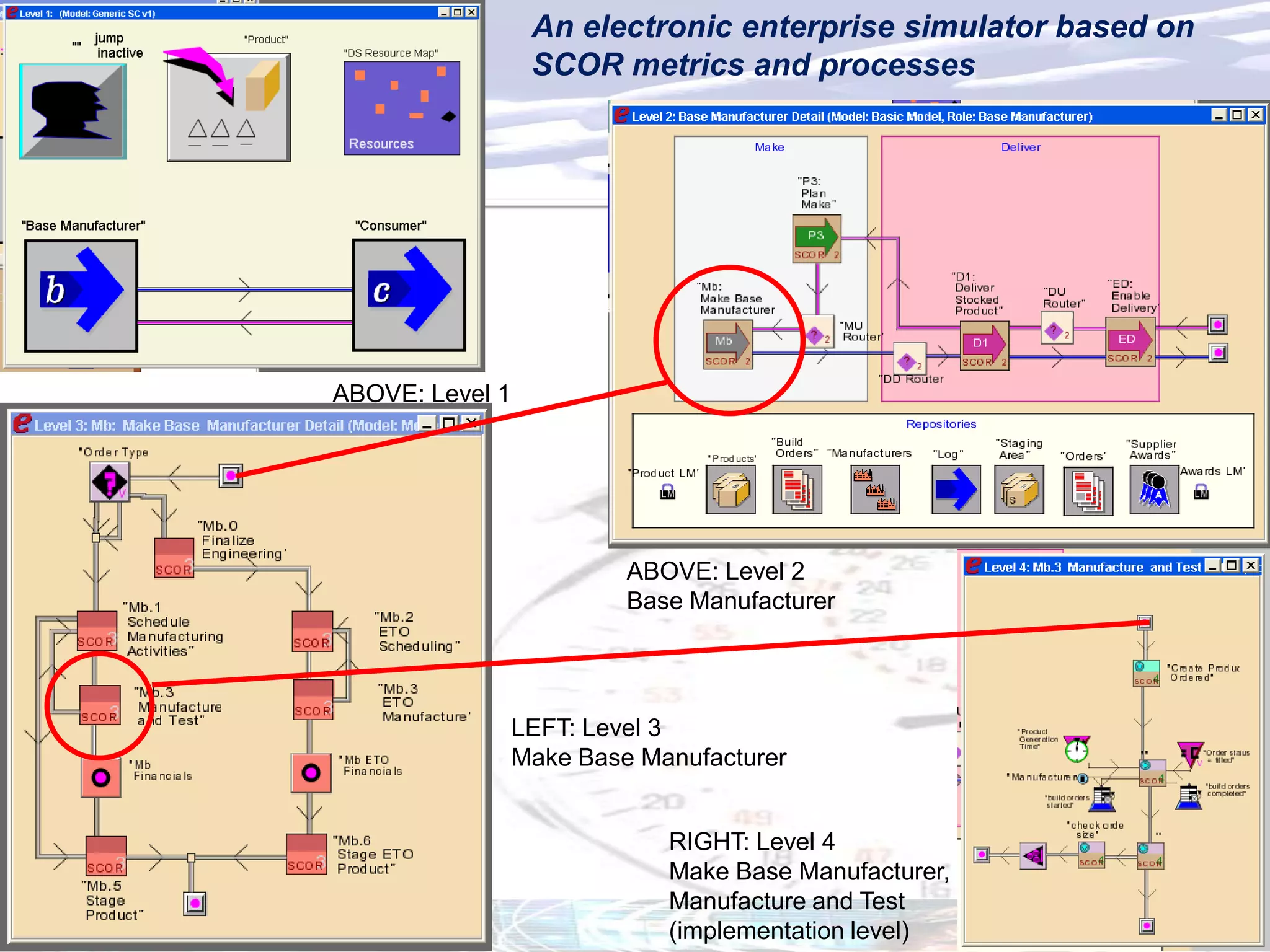

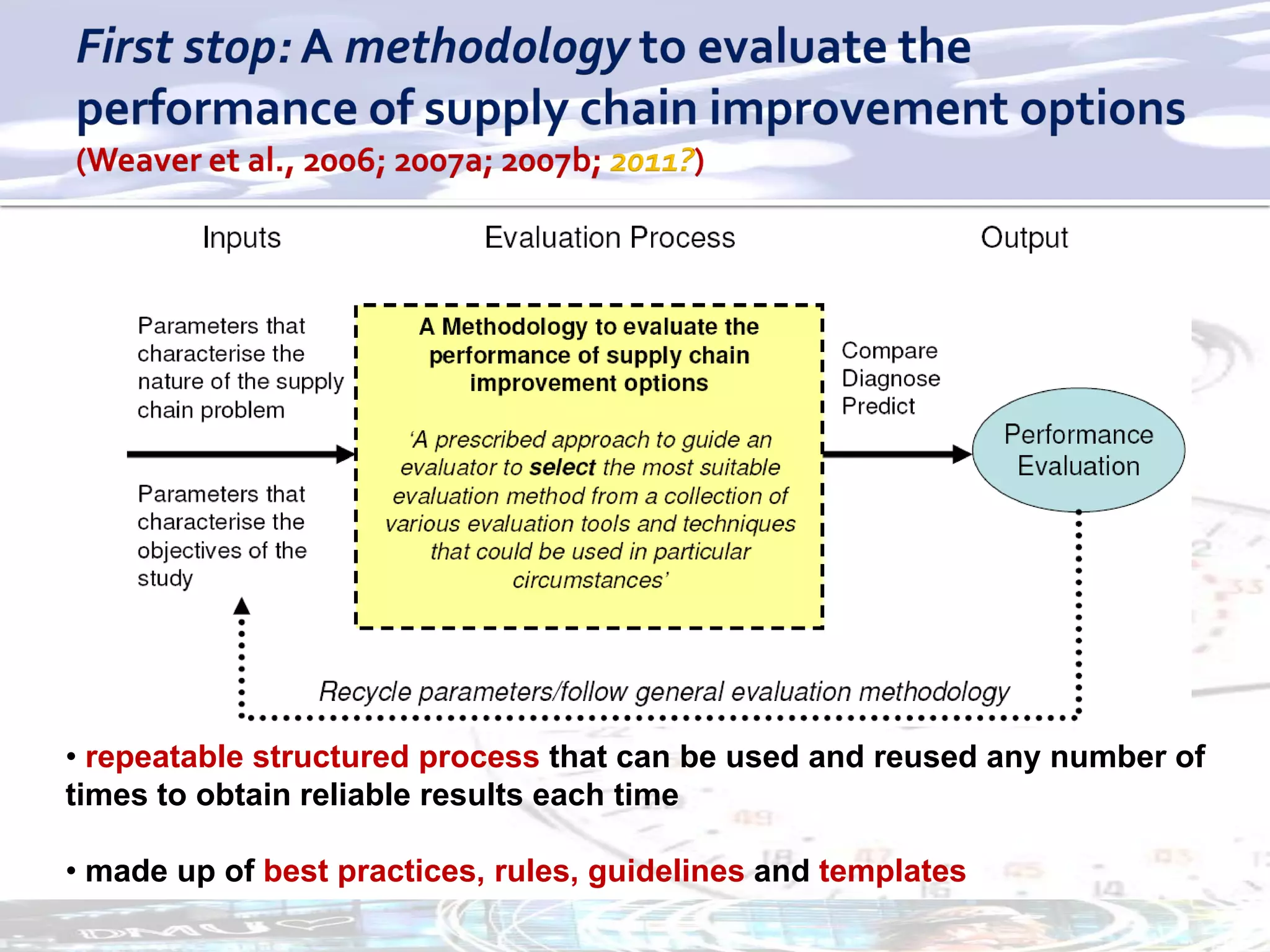

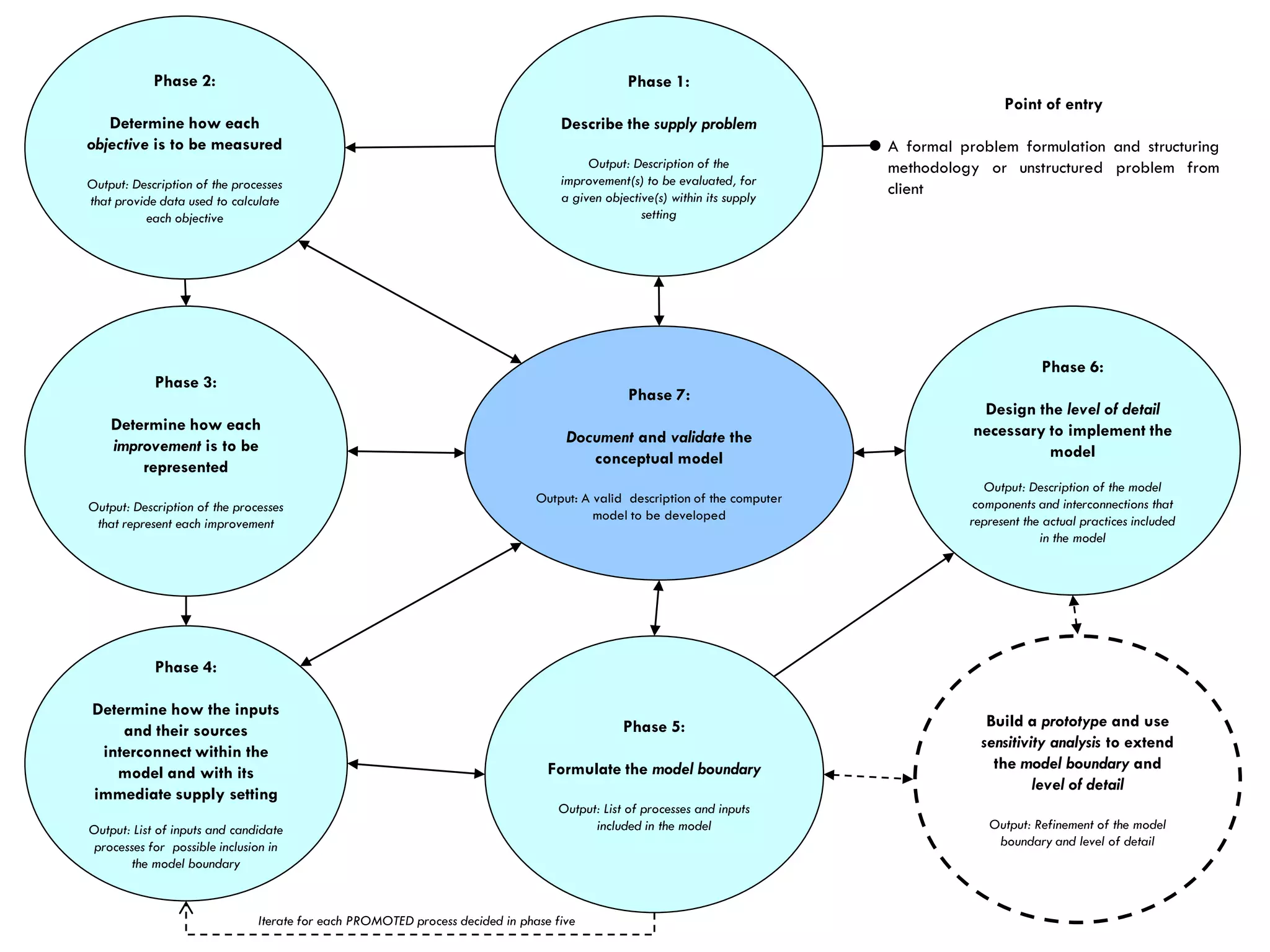

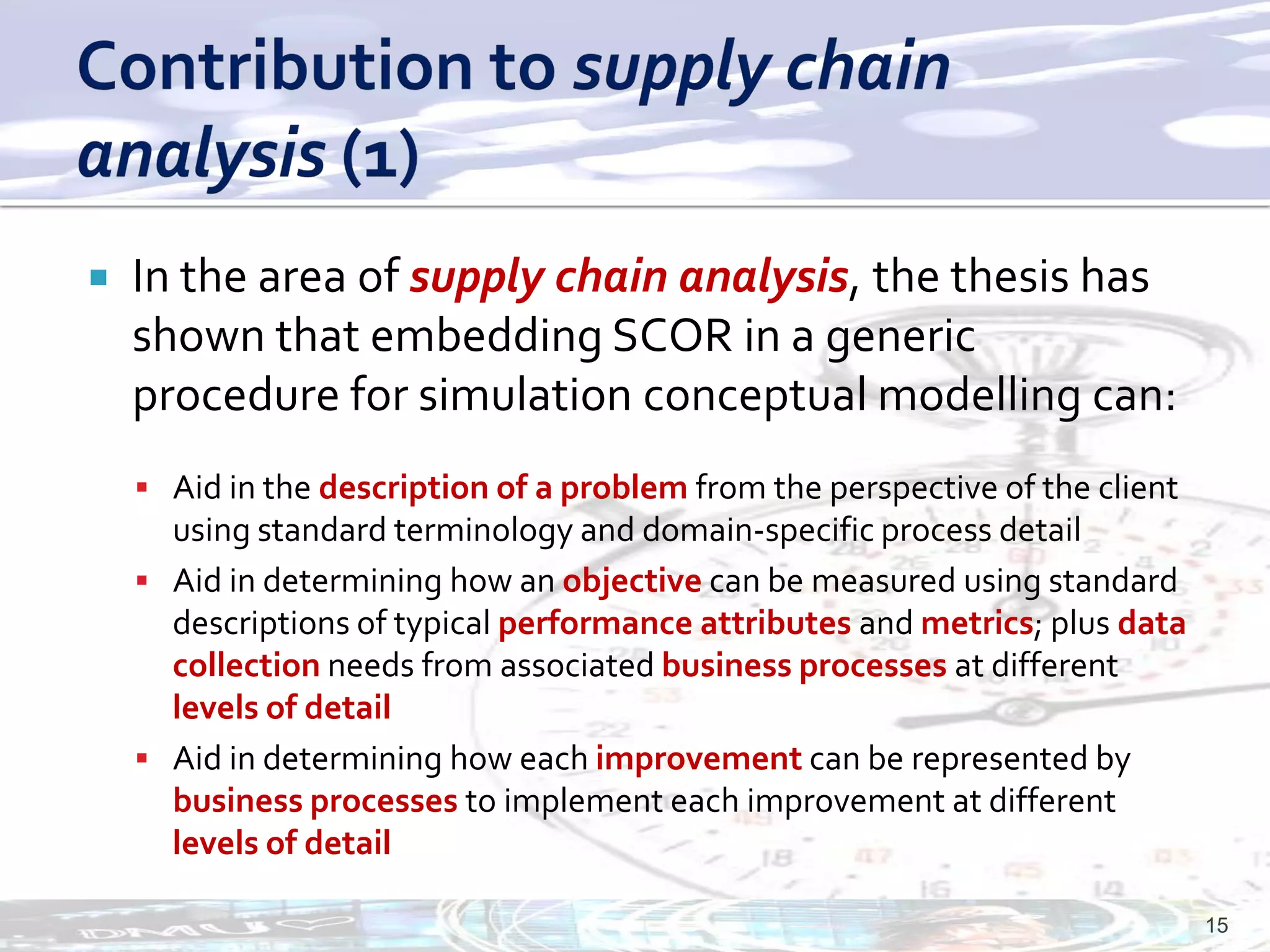

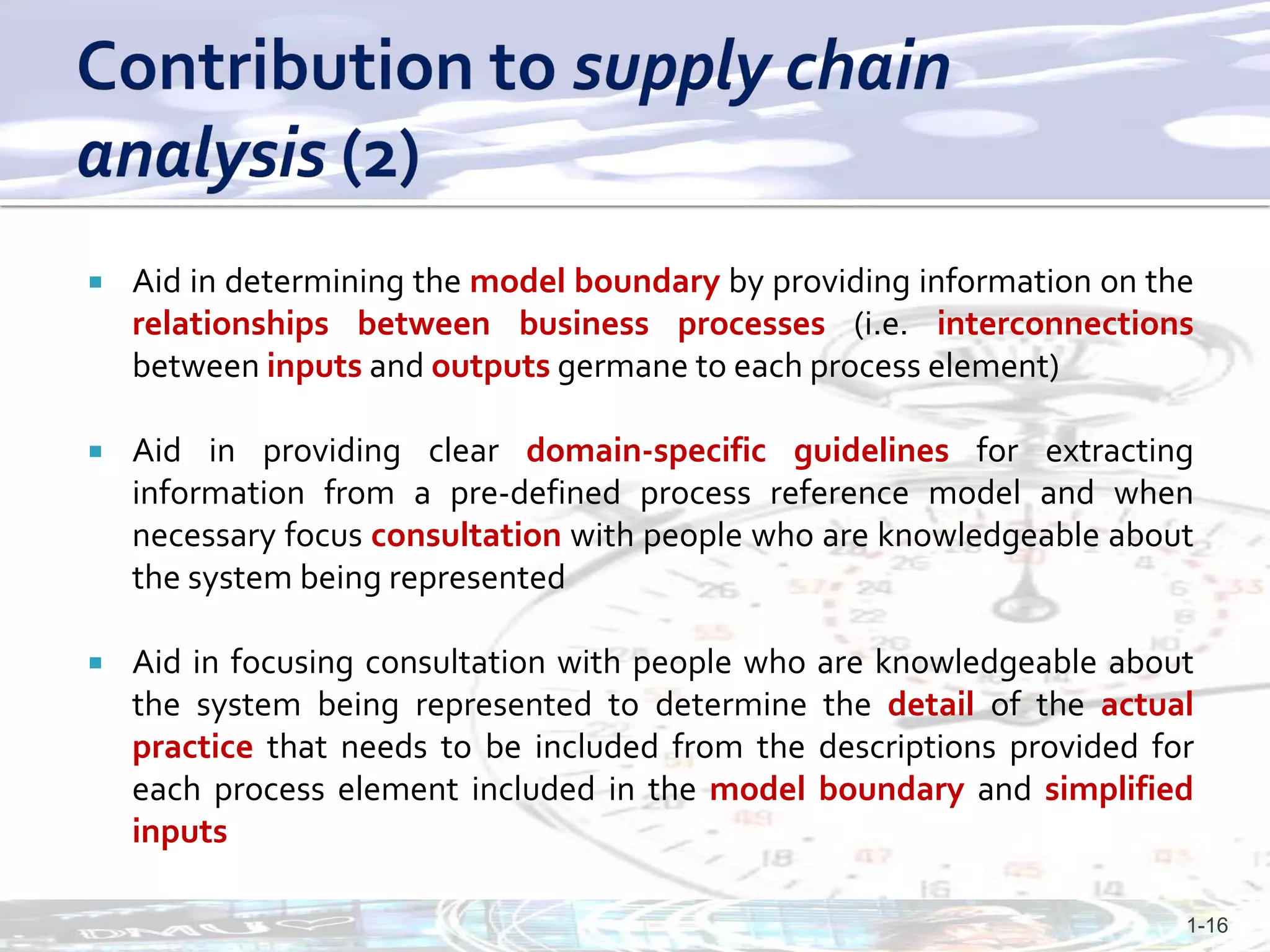

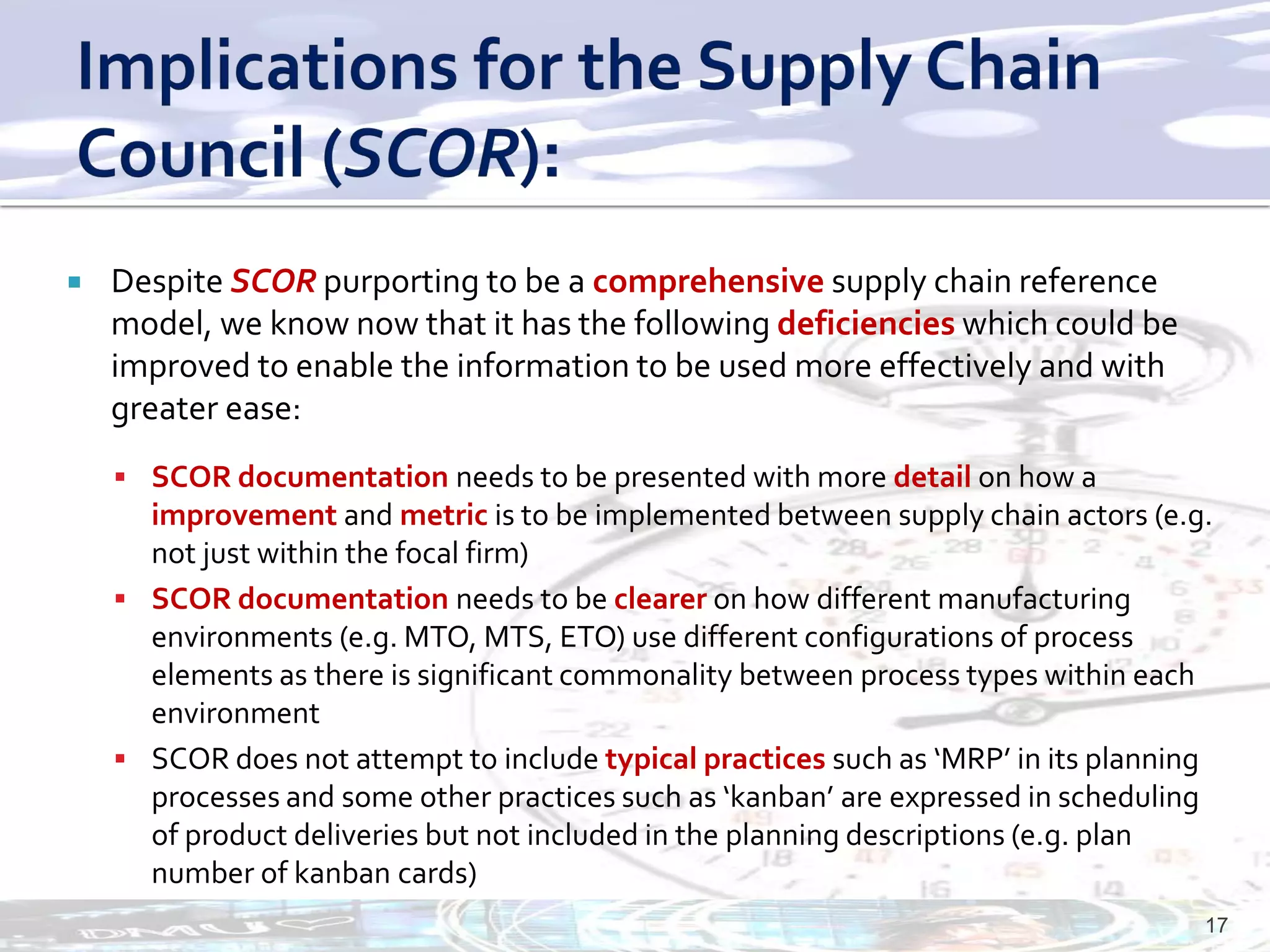

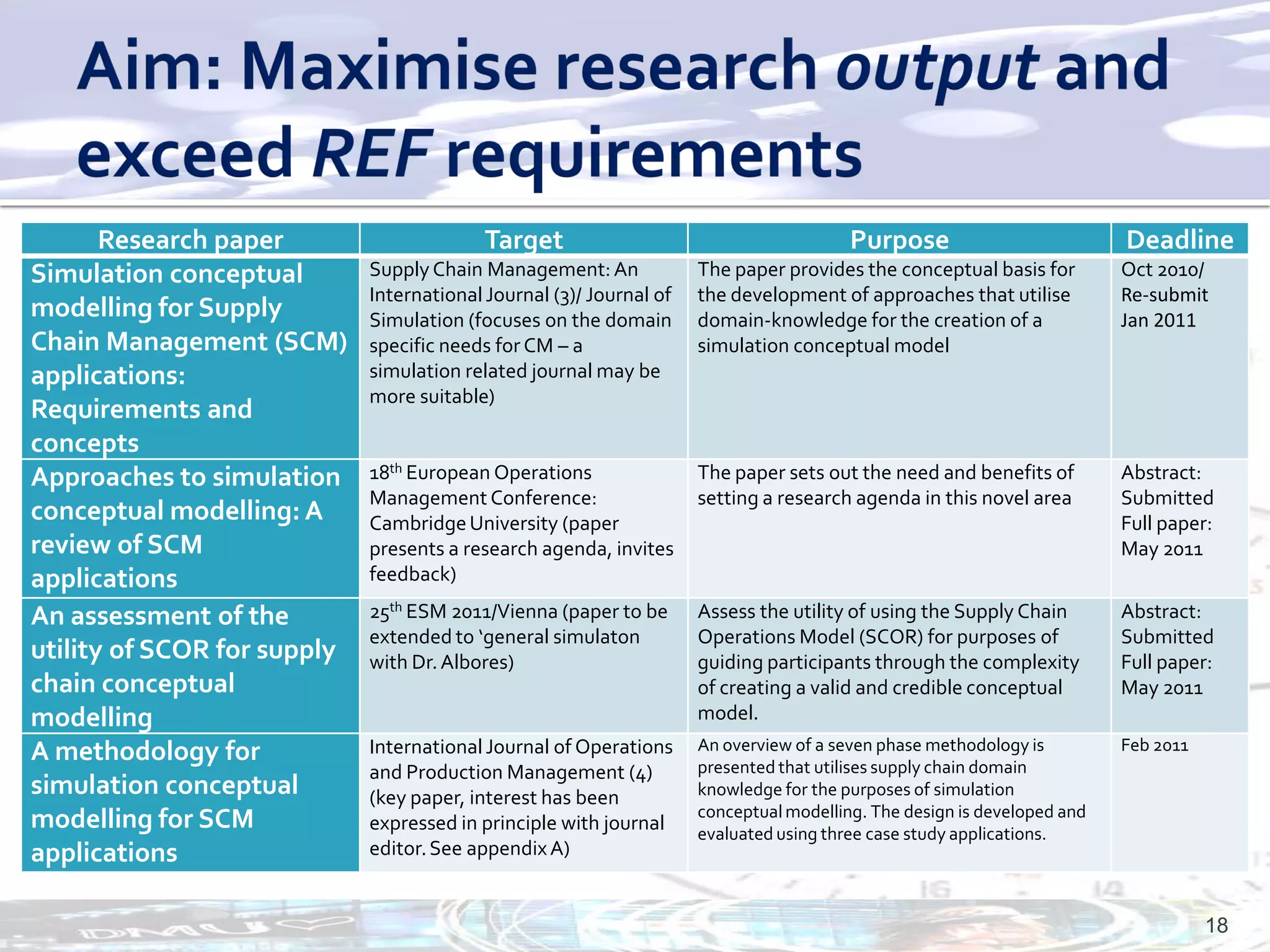

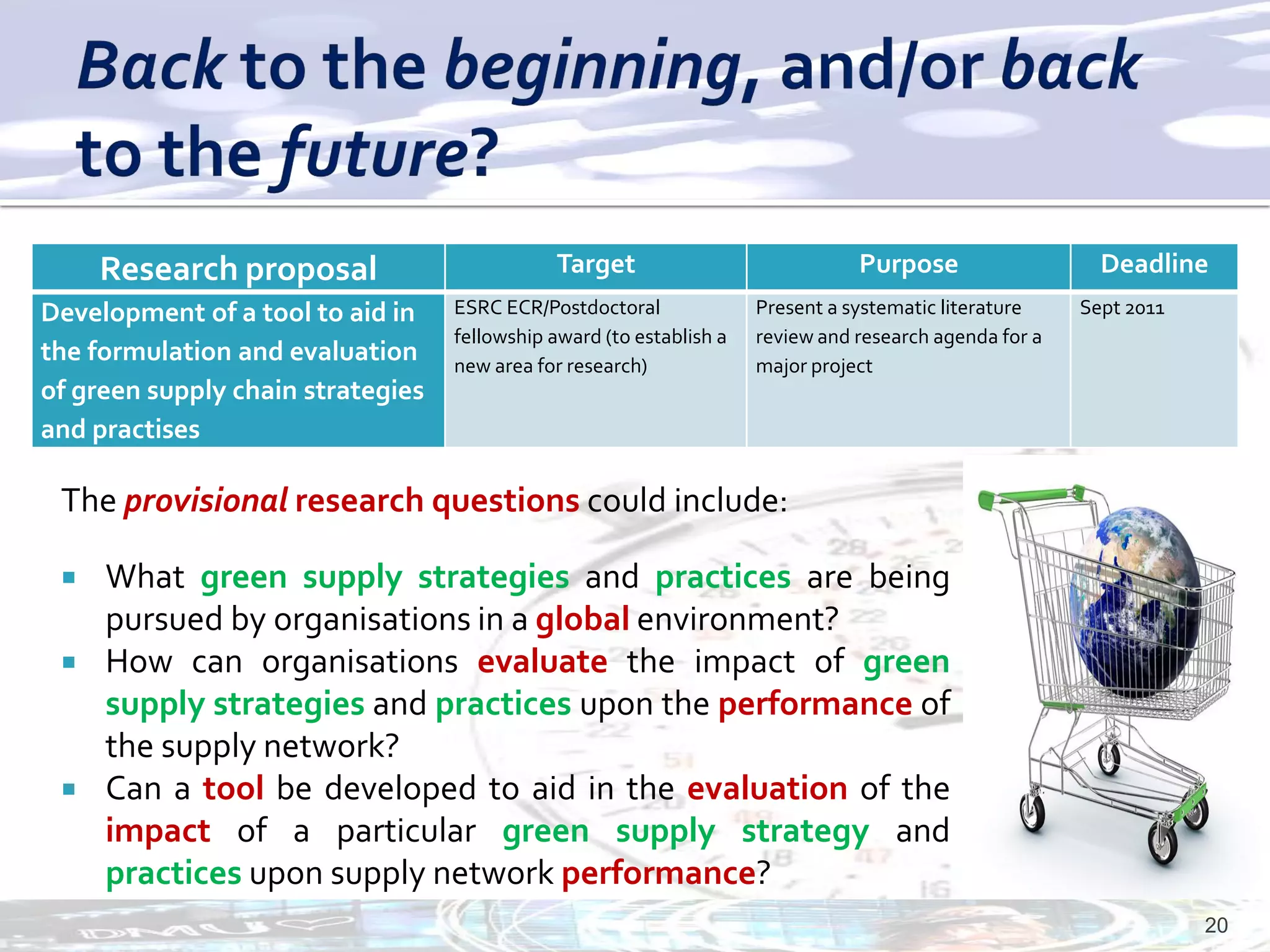

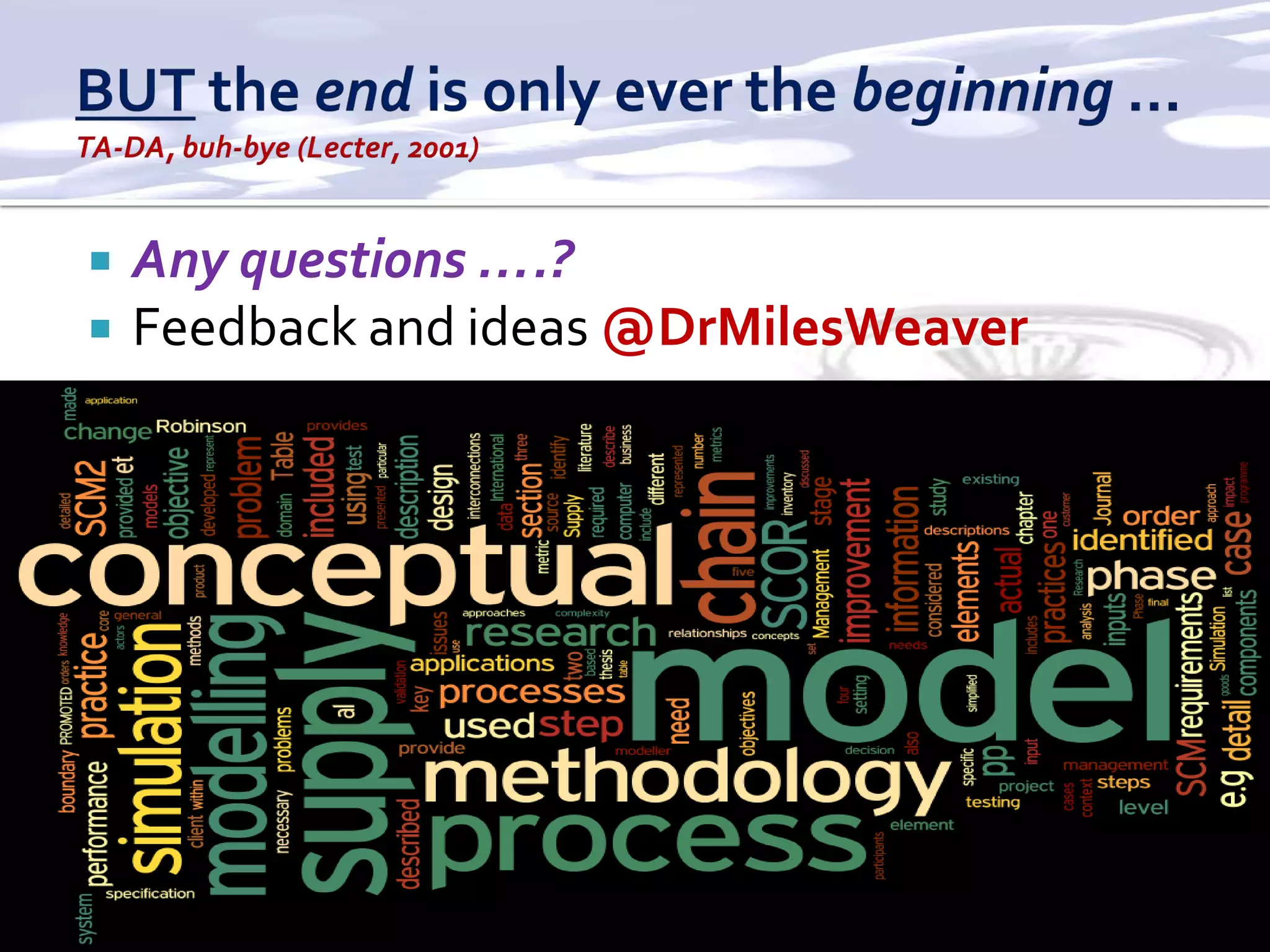

This document discusses the journey of a PhD research project on supply chain management. It begins by describing the start, middle, and end of the research journey. It then discusses challenges faced while conducting the research and getting "stuck in the middle". The document outlines future directions for research on greening supply chain management and evaluating supply chain performance through simulation. It proposes using the Supply Chain Operations Reference (SCOR) model combined with enterprise simulation to describe, measure, and evaluate different supply chain configurations and strategies.