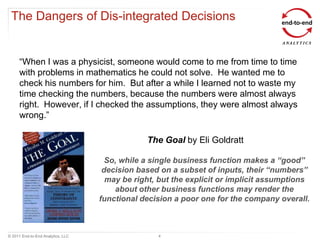

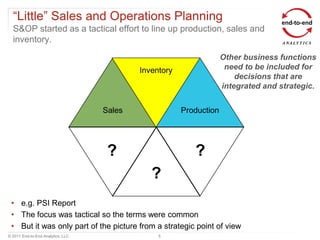

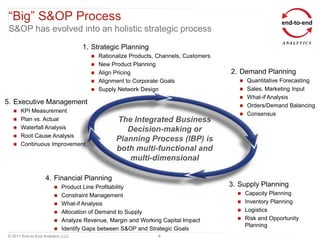

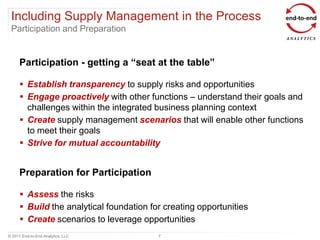

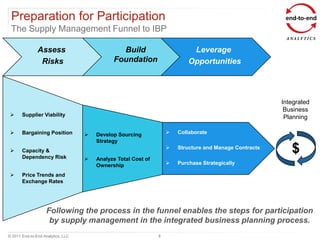

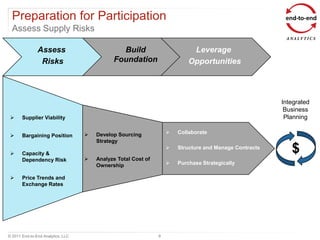

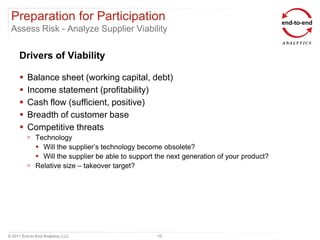

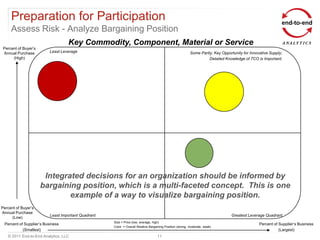

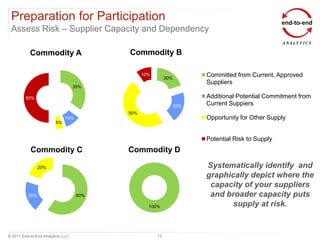

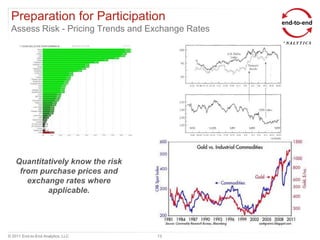

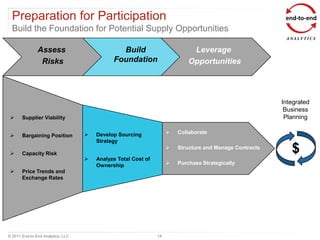

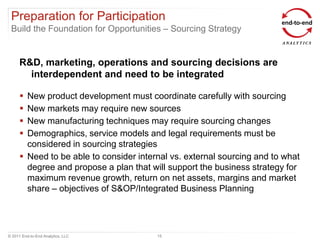

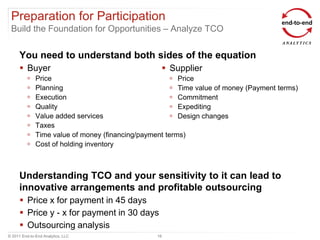

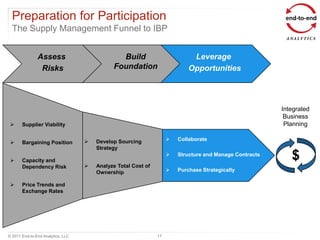

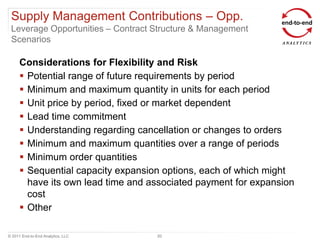

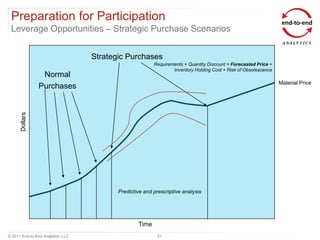

The document discusses how supply management can better inform integrated business planning processes. It argues that supply management needs to have a seat at the table and prepare by assessing risks, building an analytical foundation, and creating opportunities through various scenarios. These scenarios could leverage opportunities through collaboration, contract structuring, and strategic purchasing approaches. Getting supply management involved helps ensure decisions are made using a holistic perspective rather than just individual functional views.