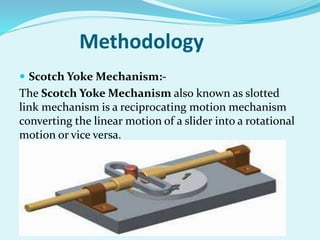

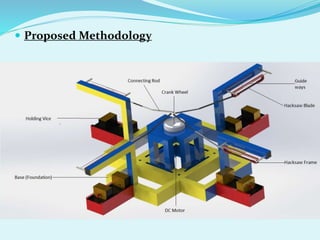

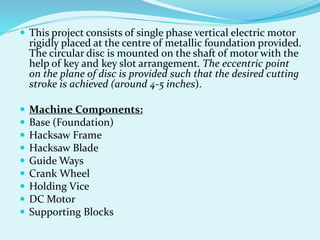

The document outlines the development of a modernized four-way hacksaw machine utilizing a scotch yoke mechanism to enhance cutting efficiency of various materials like PVC, metal, and wood, while simplifying mass production. A literature survey references existing research on multipurpose machines and efficient cutting methods, highlighting the need for reduced human effort and material selection for better performance. The project aims to fabricate an automated model capable of cutting multiple materials simultaneously, improving upon traditional hacksaw machines, making it suitable for small industries and workshops.