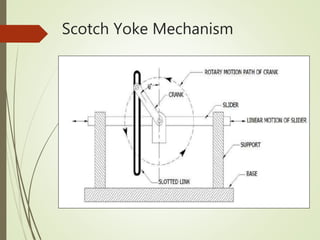

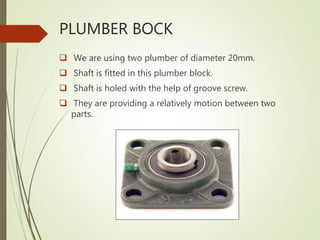

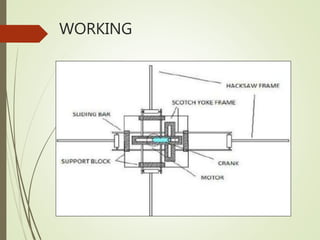

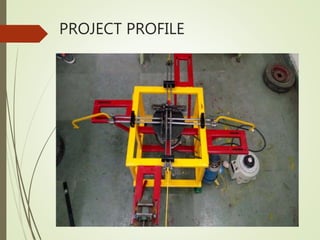

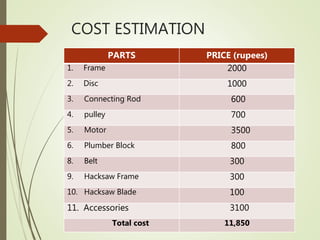

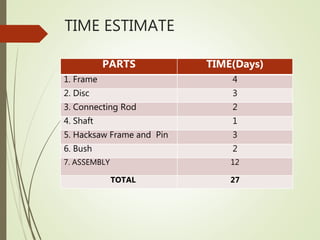

This document describes a prototype for an automatic four-way hacksaw machine. It works using a Scotch yoke mechanism to convert rotational motion from an electric motor into reciprocating motion that drives four hacksaw blades simultaneously. The main components are a frame, disc, connecting rods, hacksaw blades, motor, and belt. This design allows four pieces of material to be cut at once, improving productivity over single-blade hacksaw machines. Potential future improvements include adding automation controls using a microcontroller.