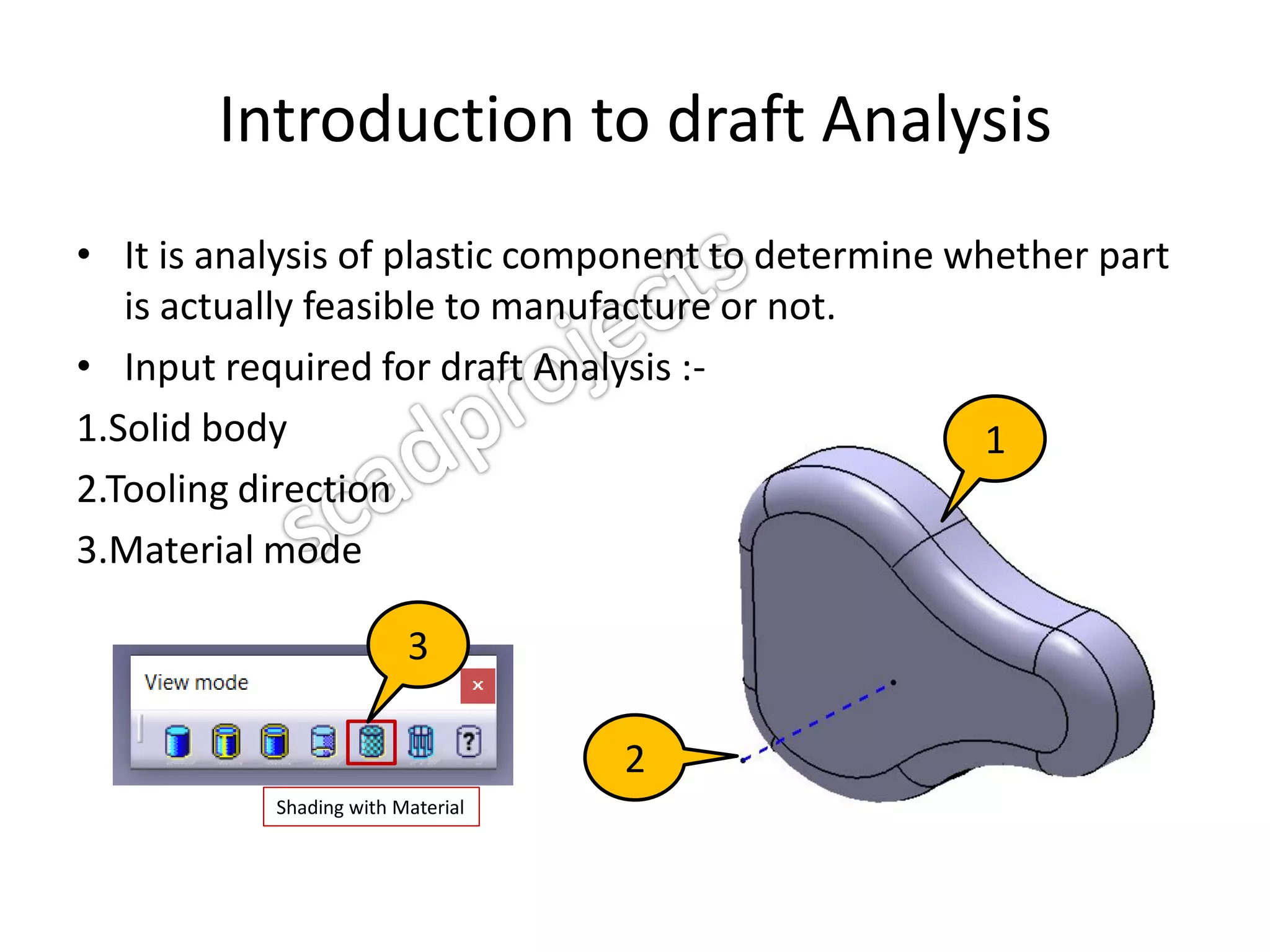

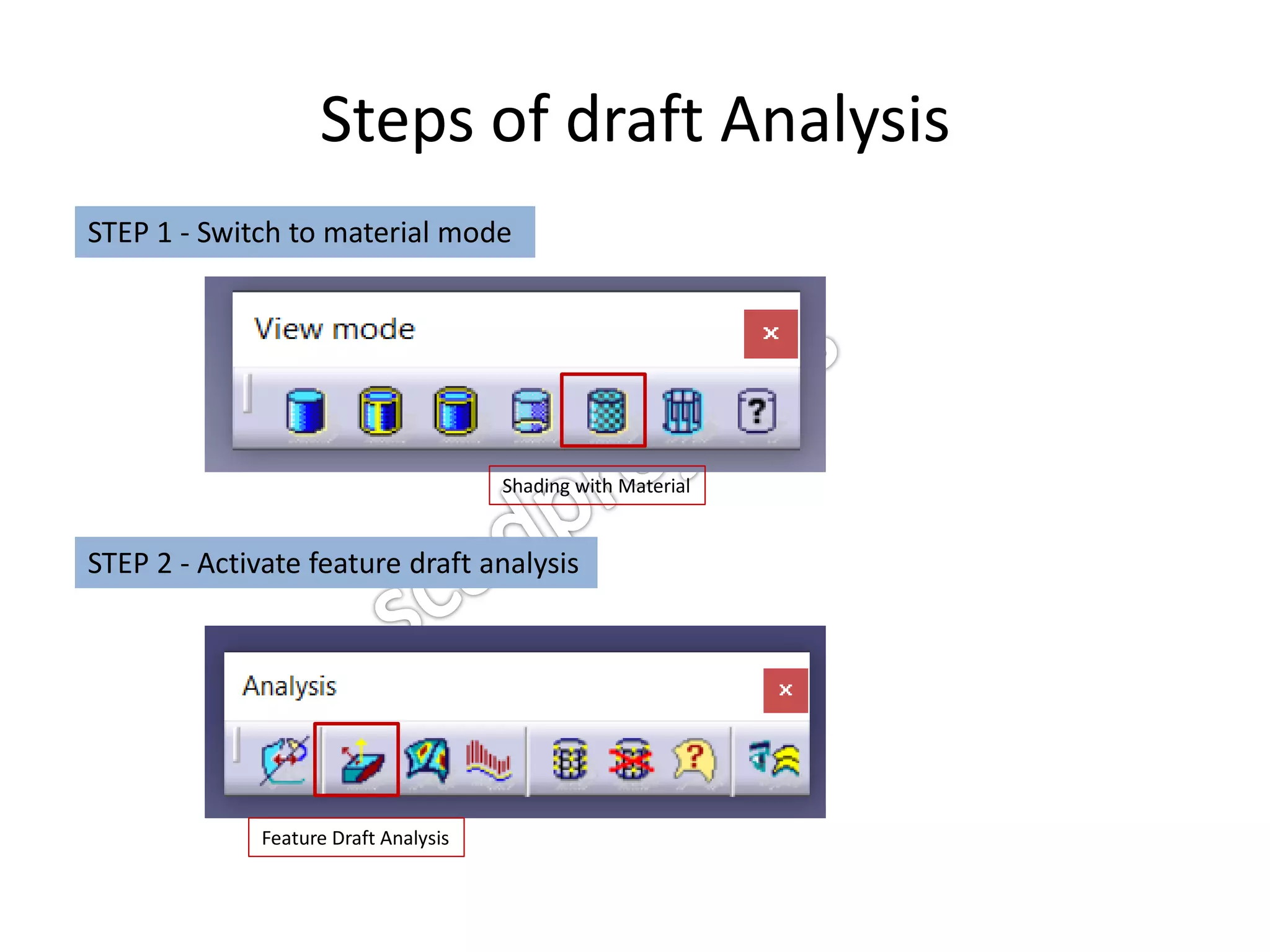

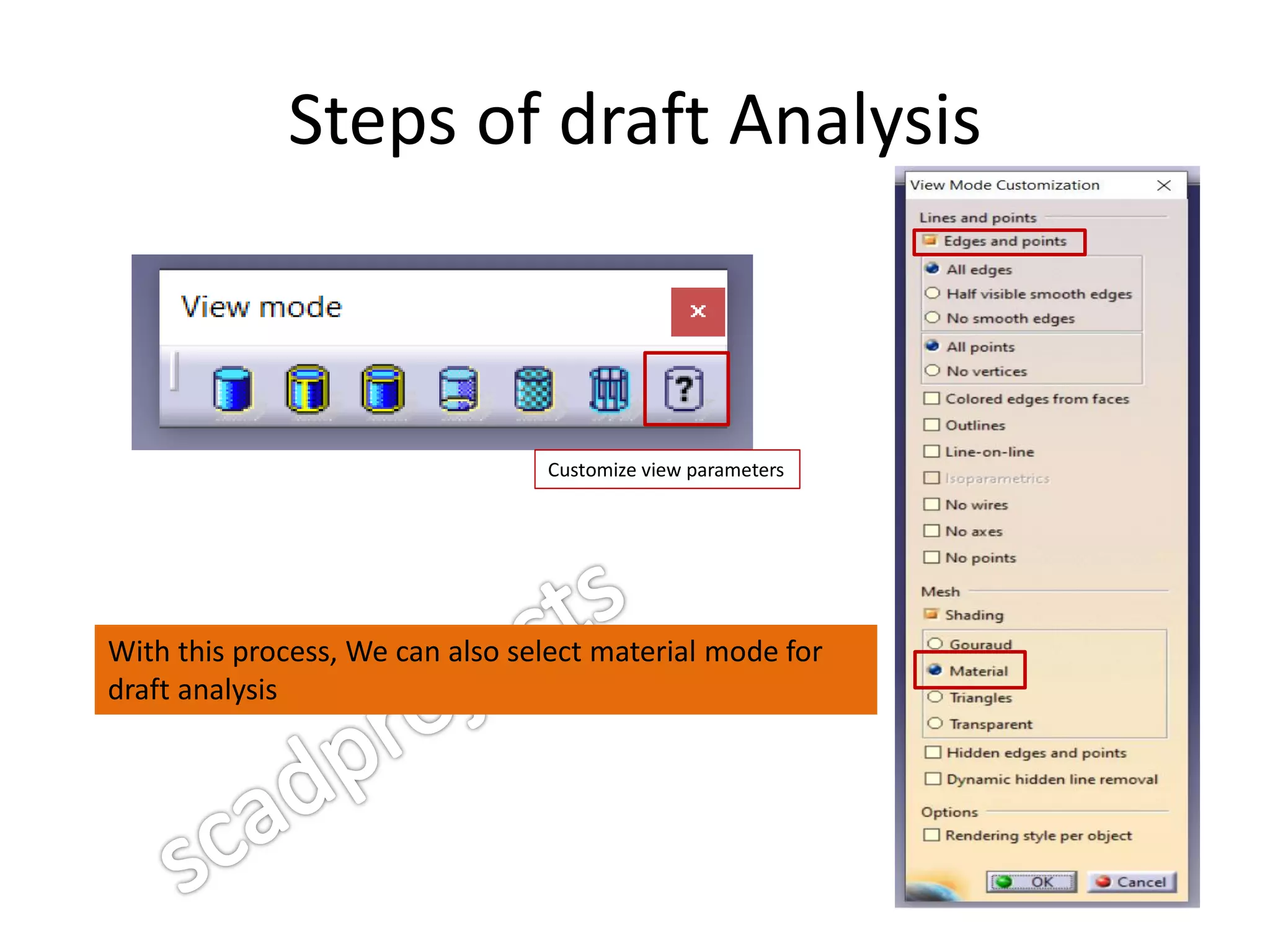

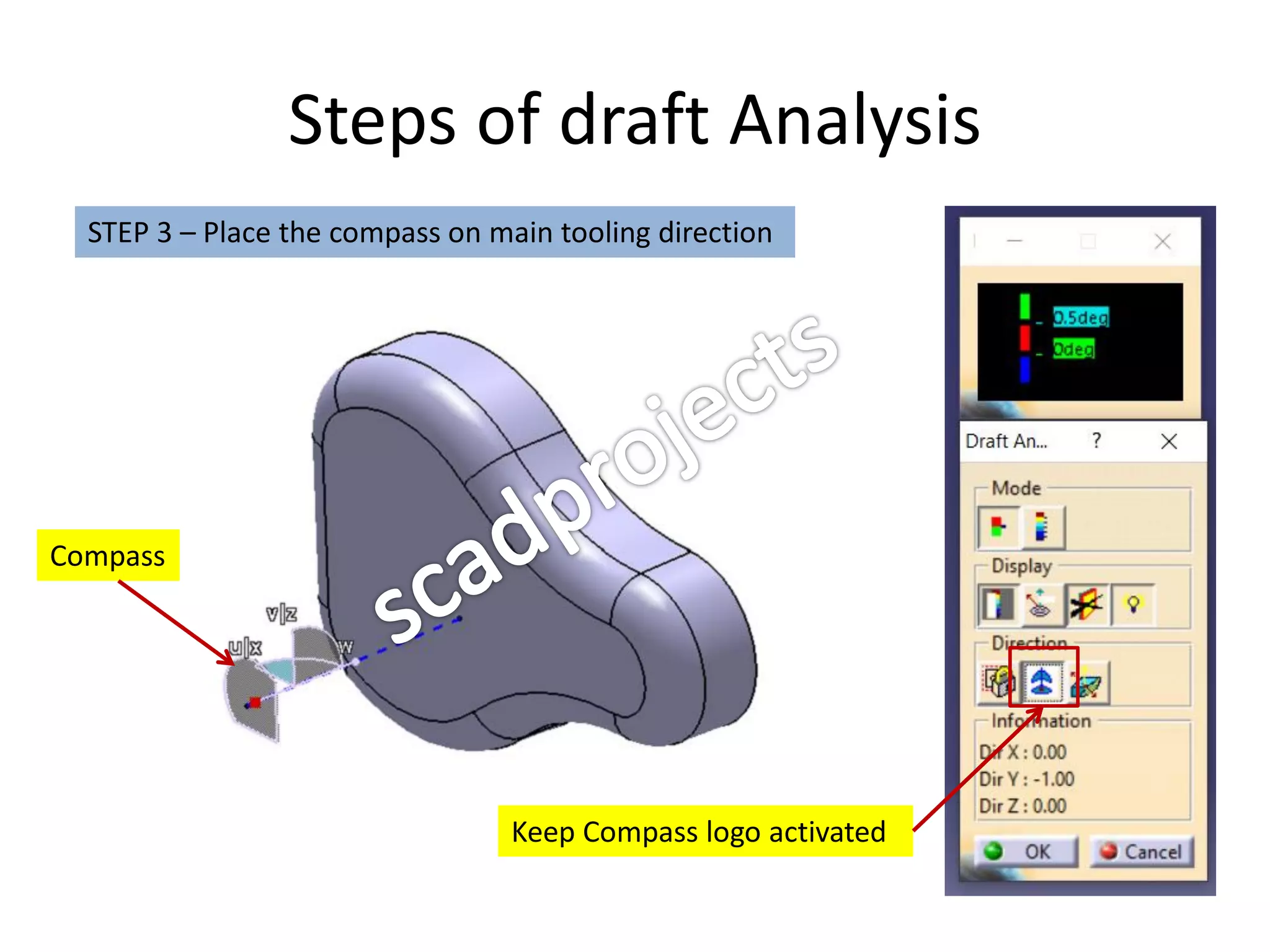

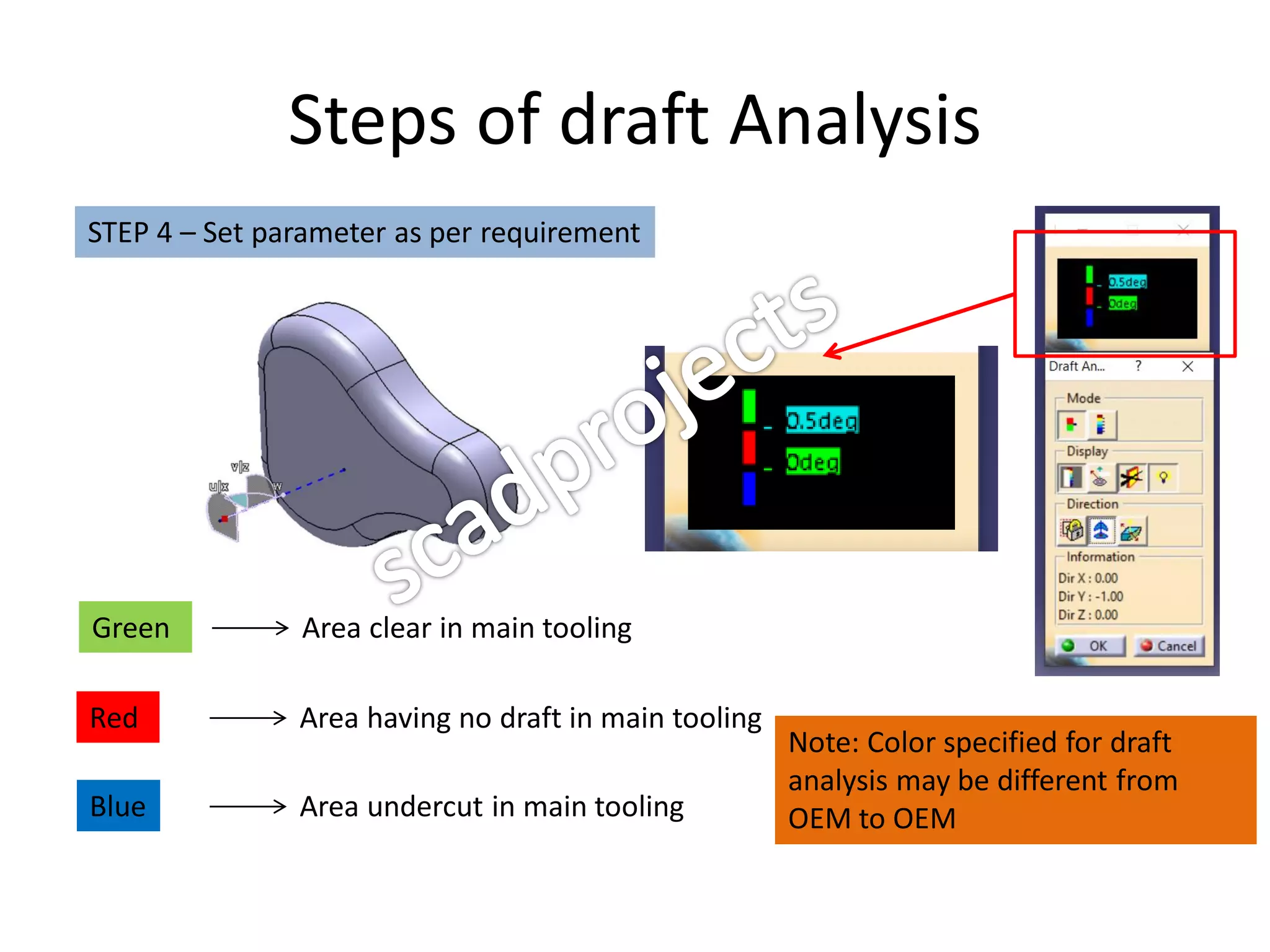

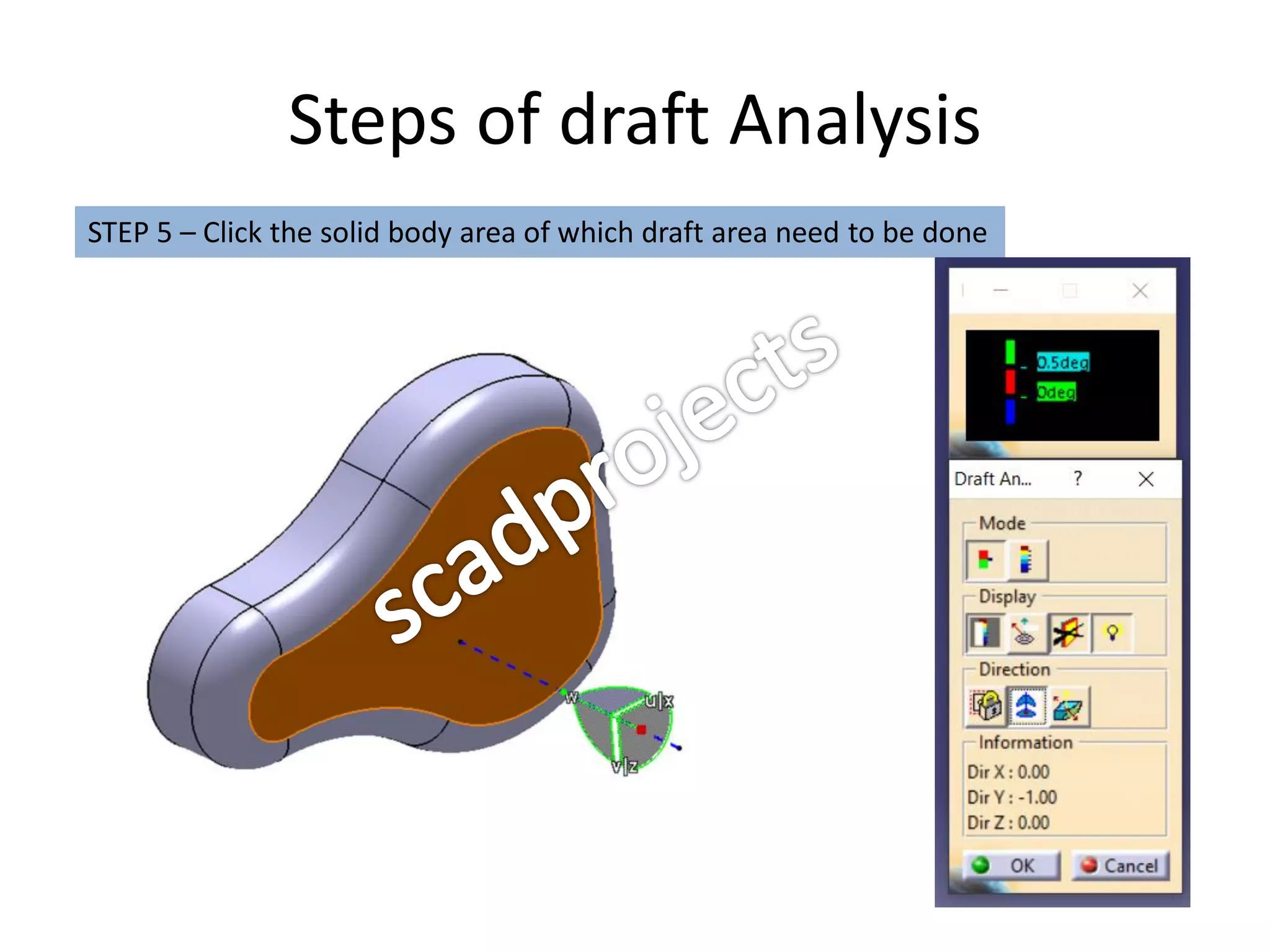

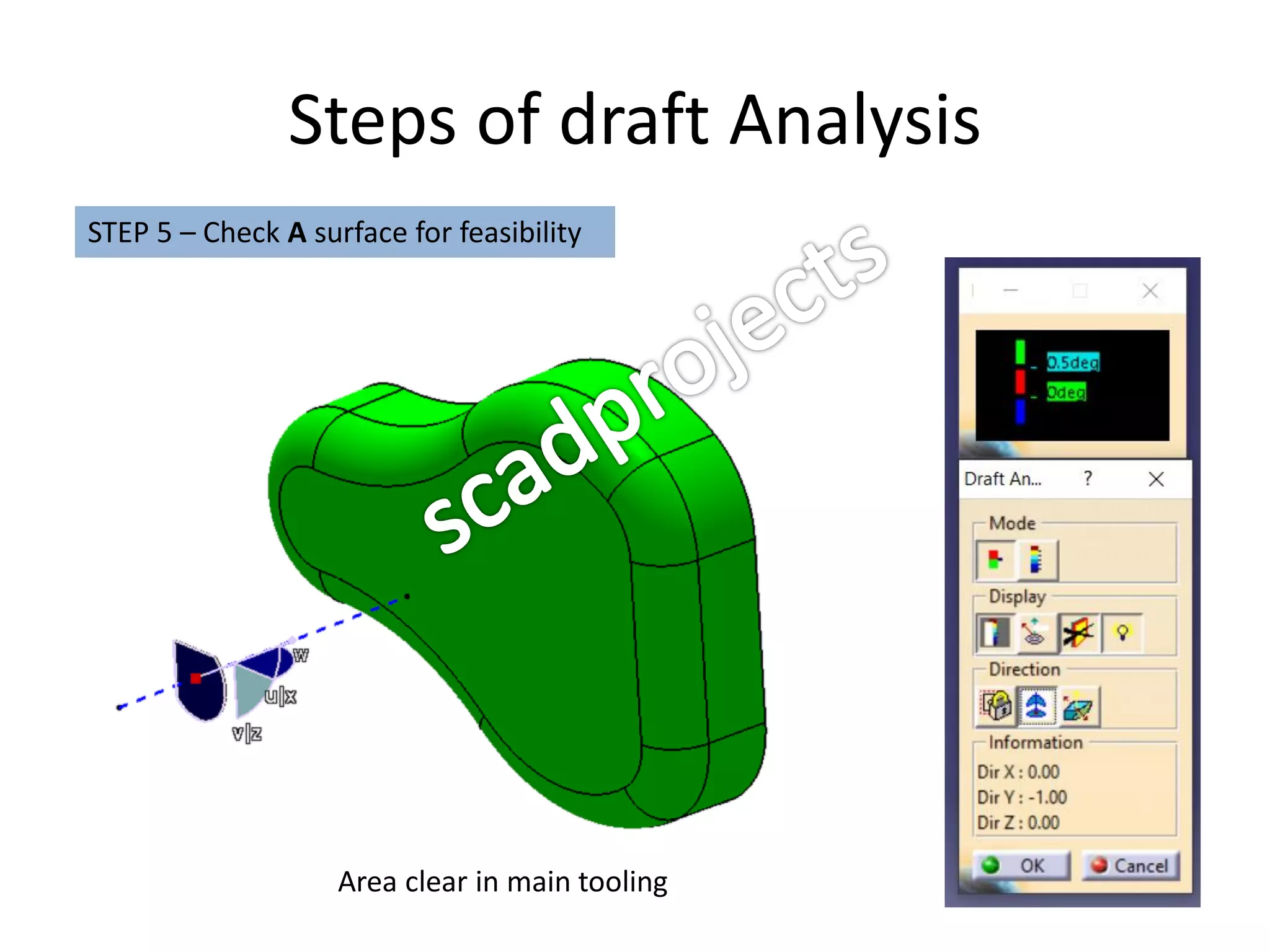

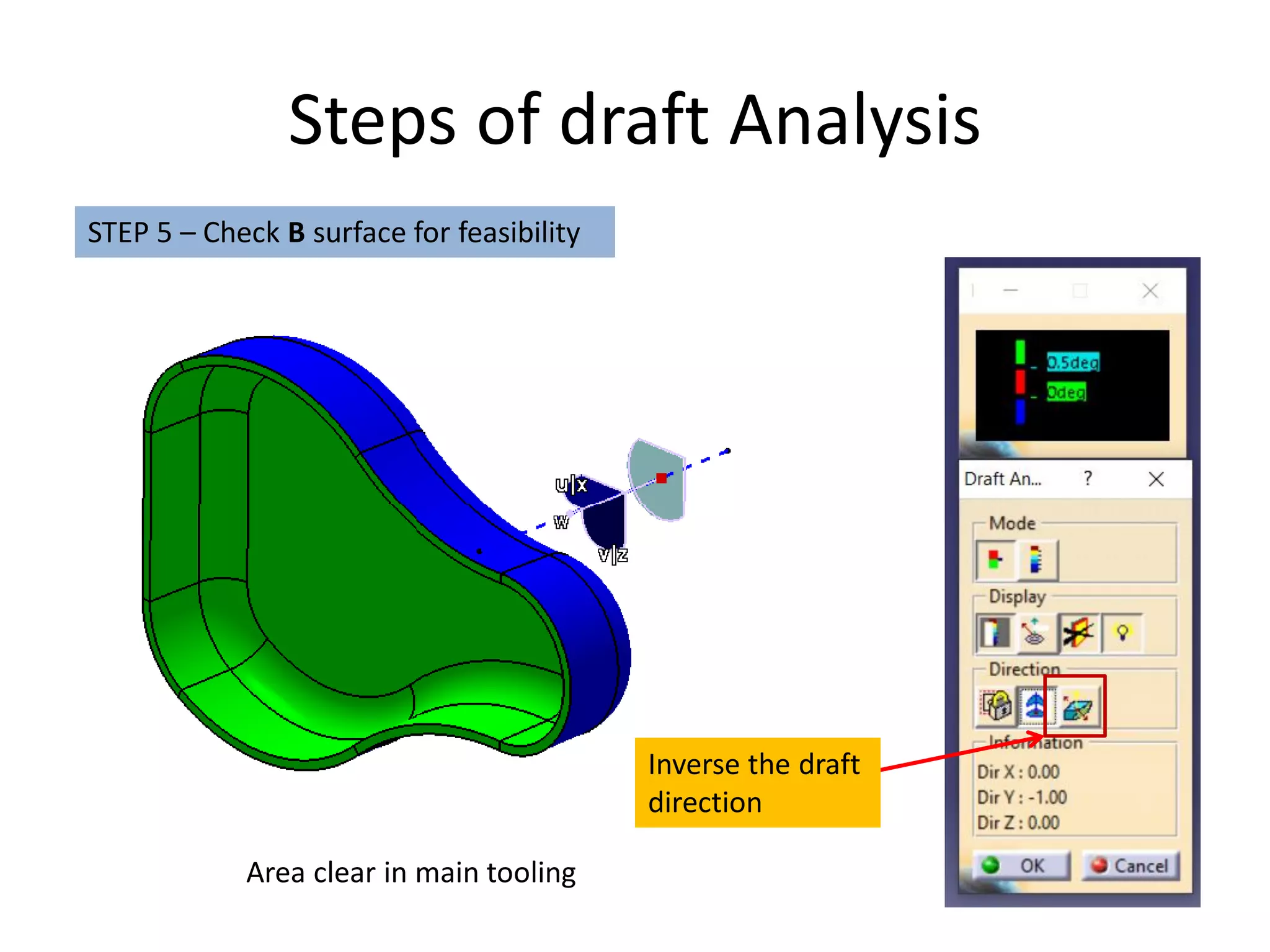

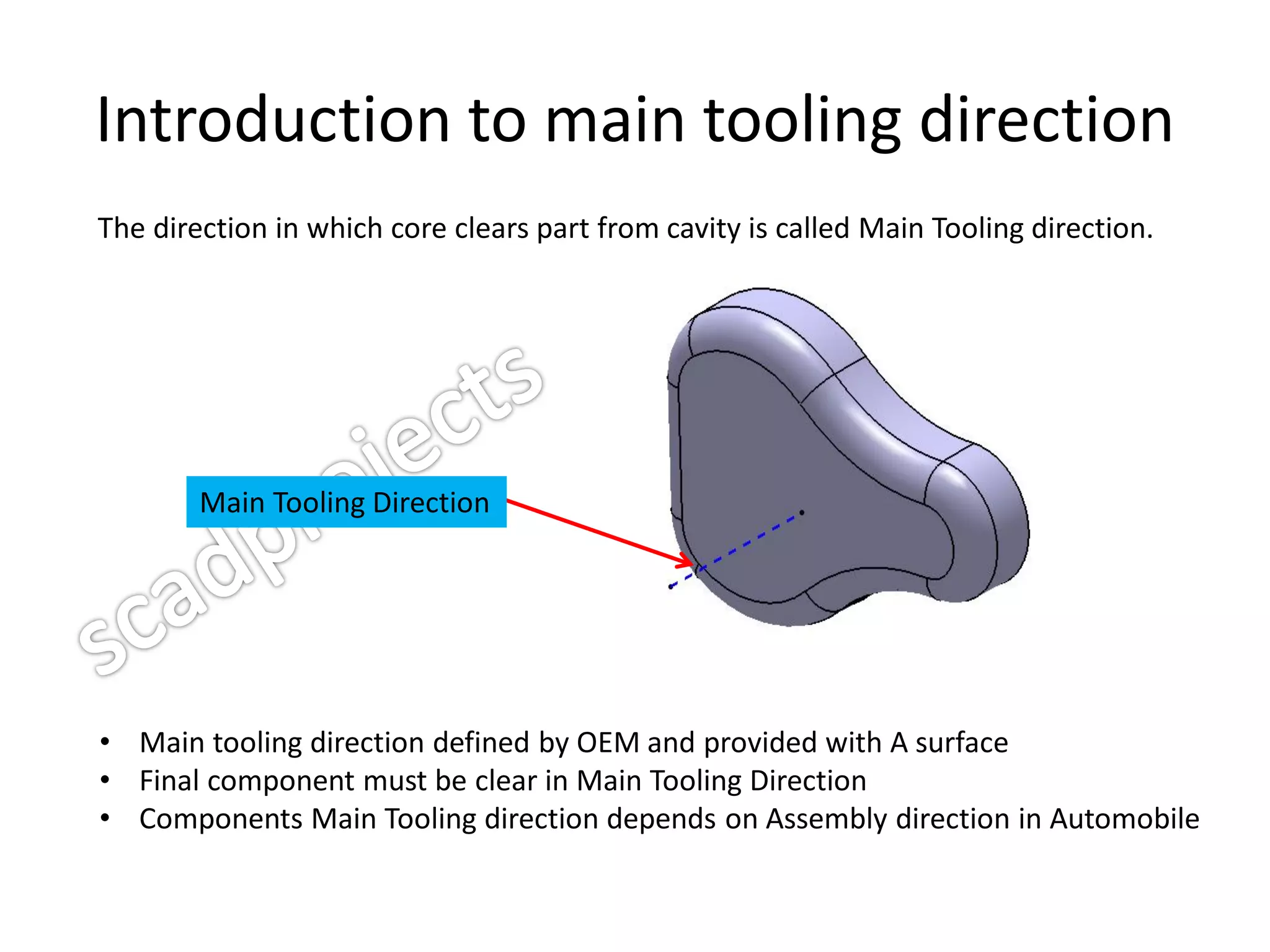

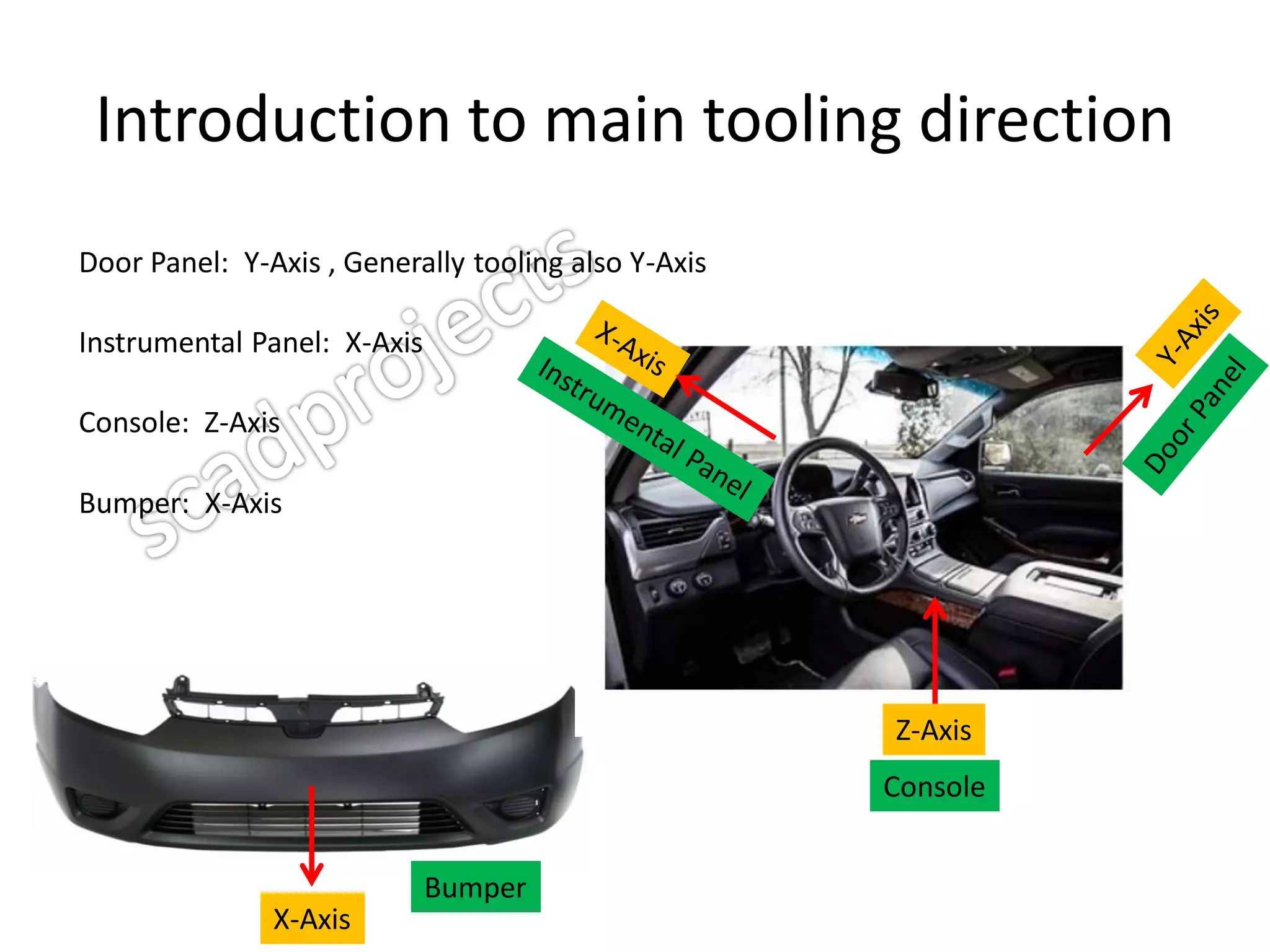

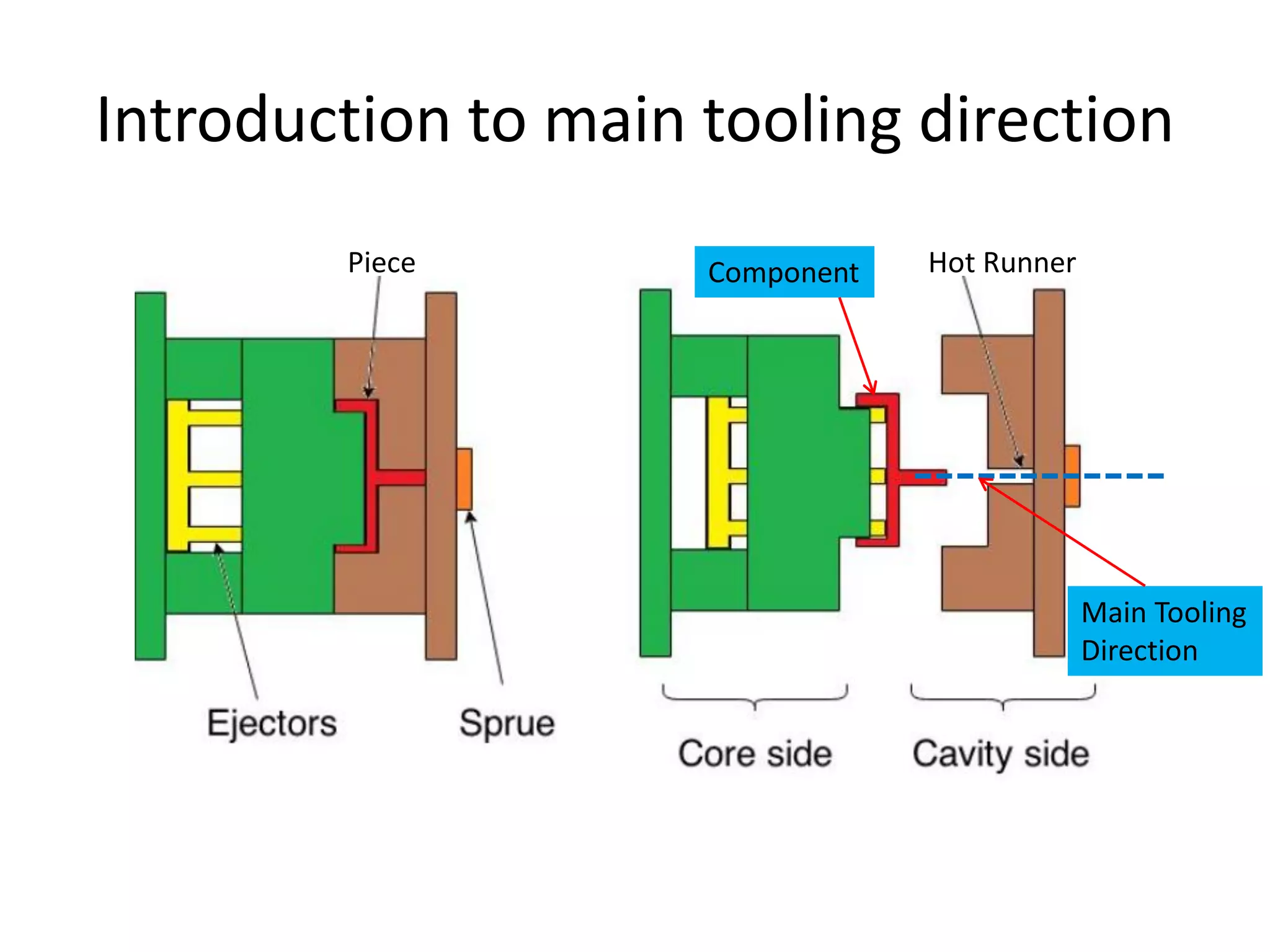

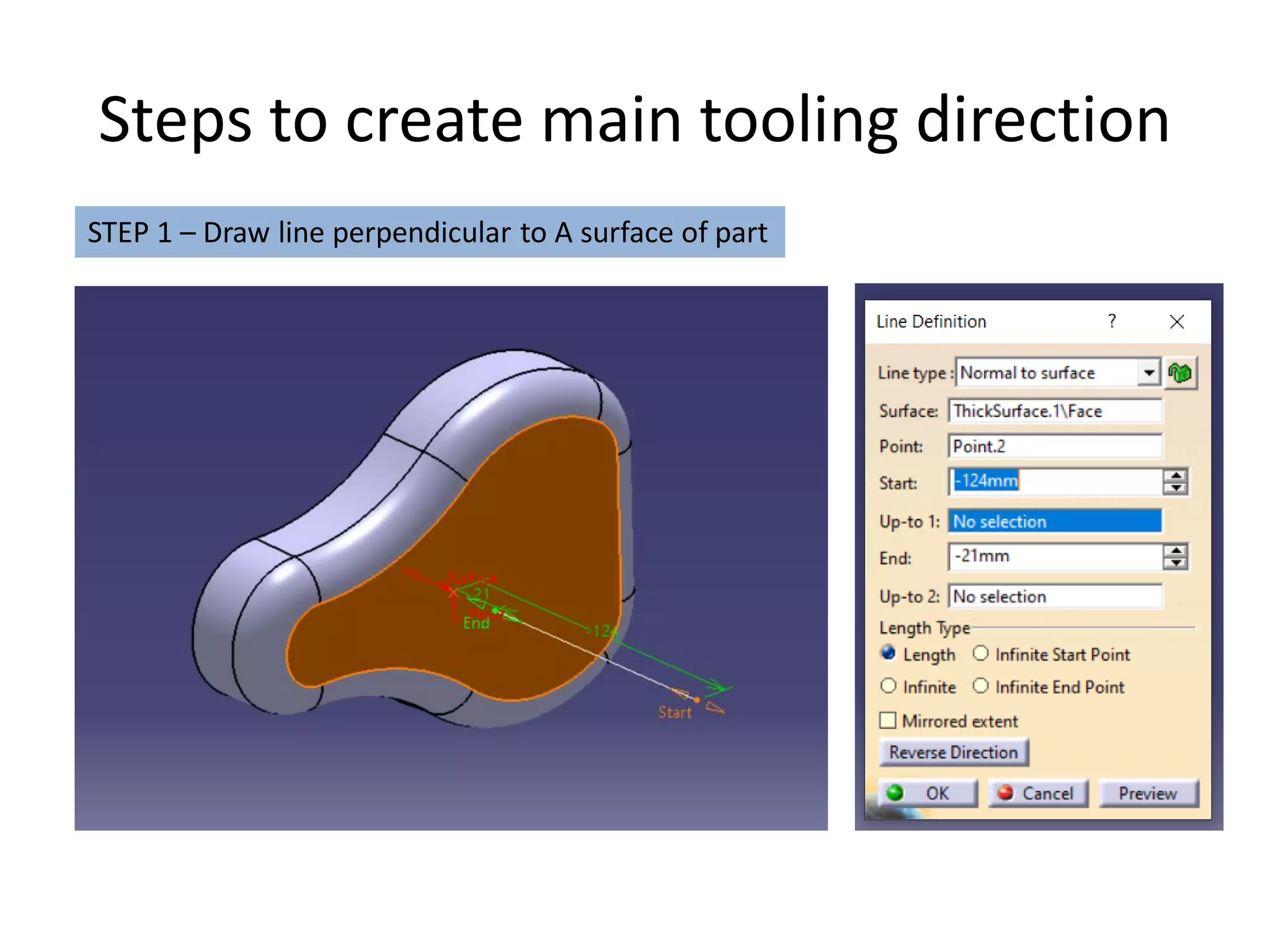

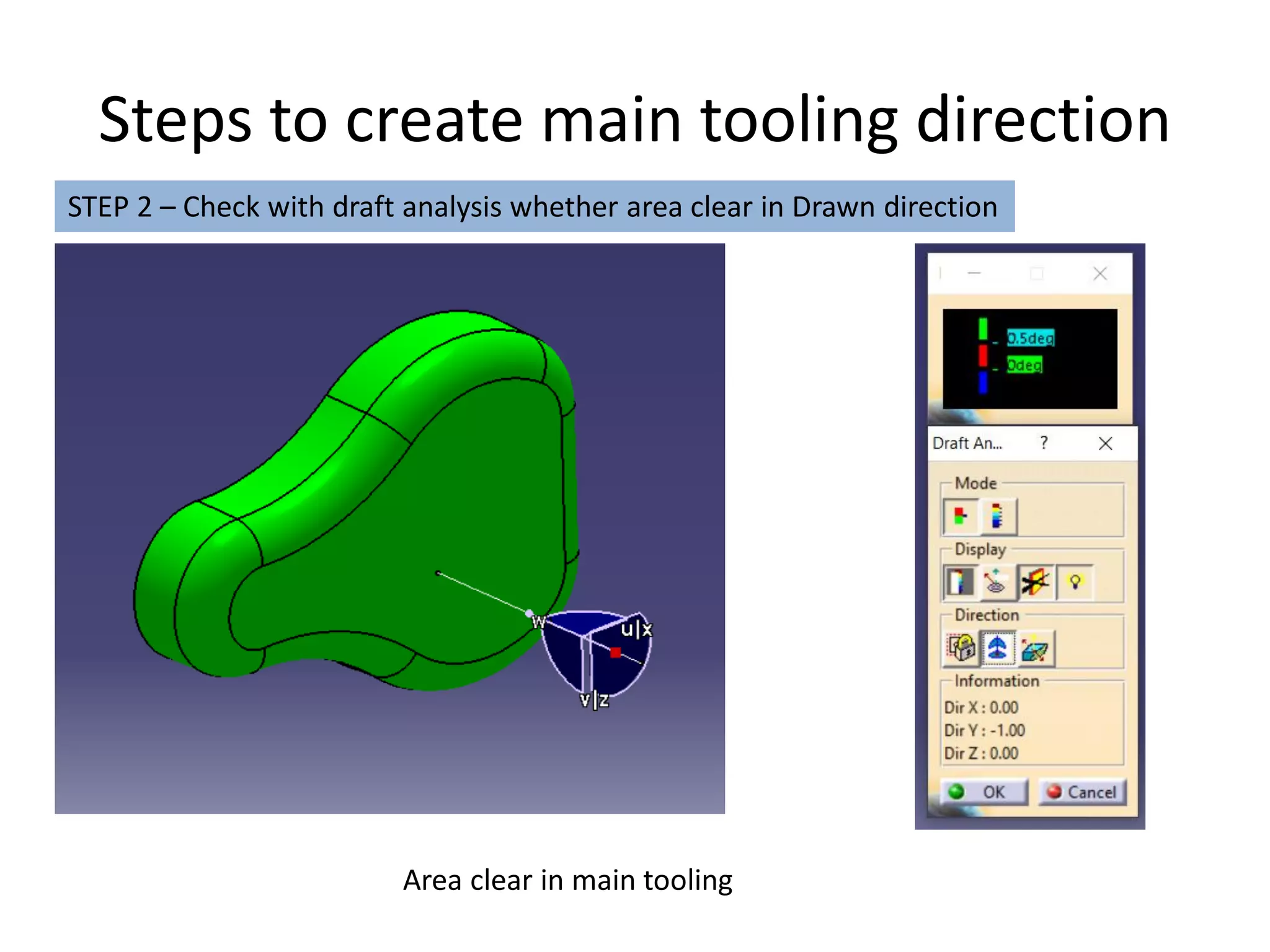

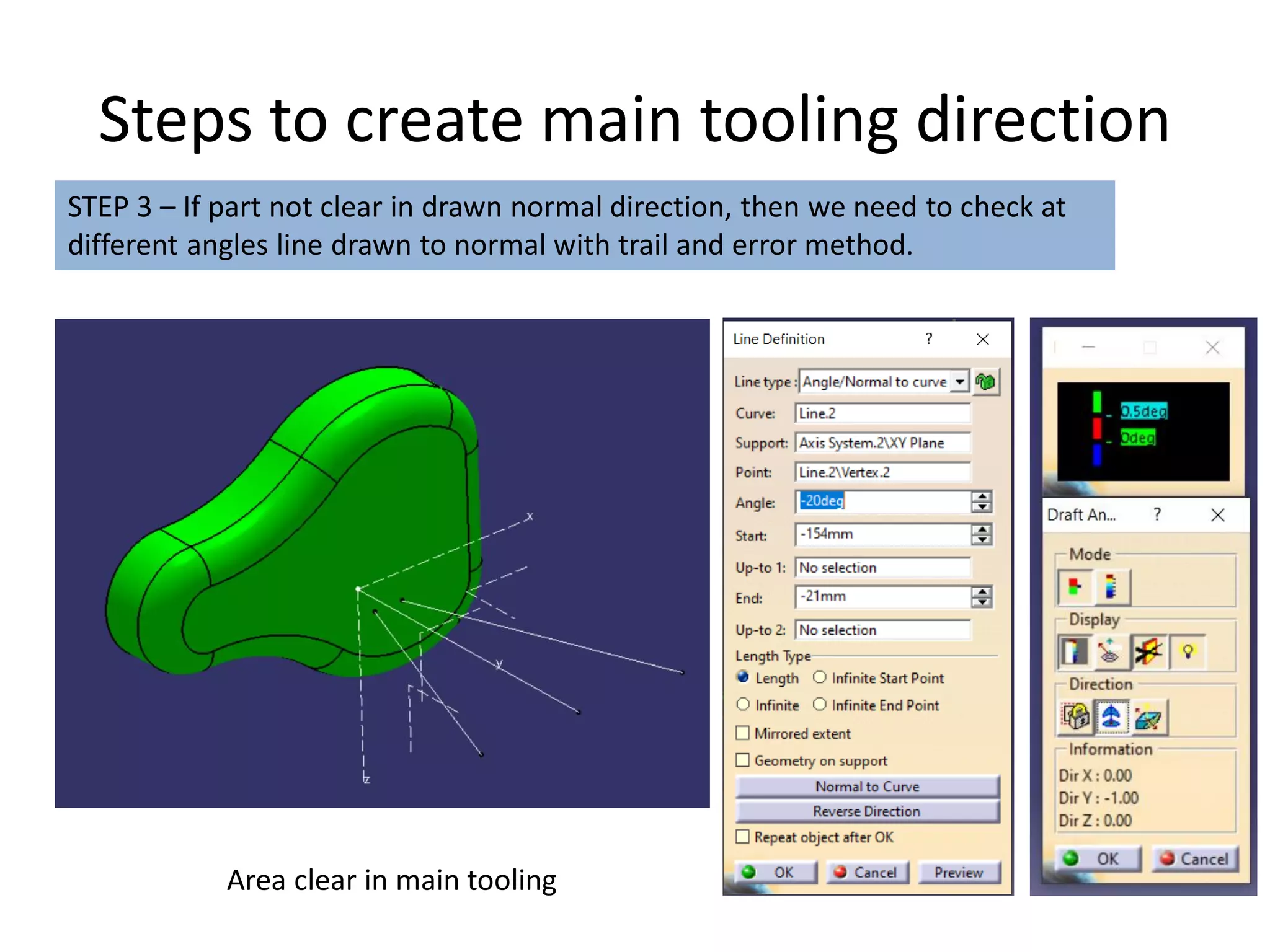

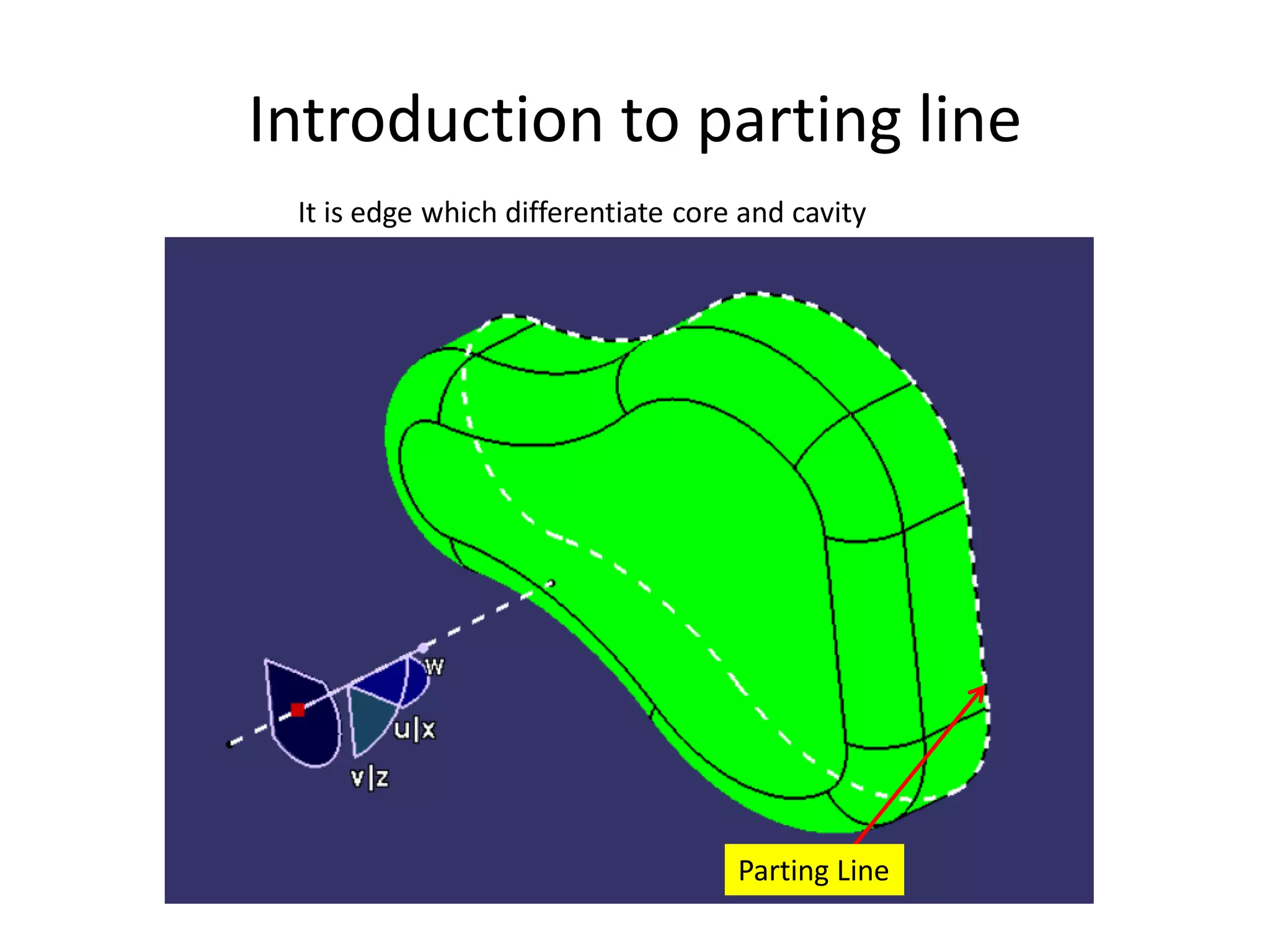

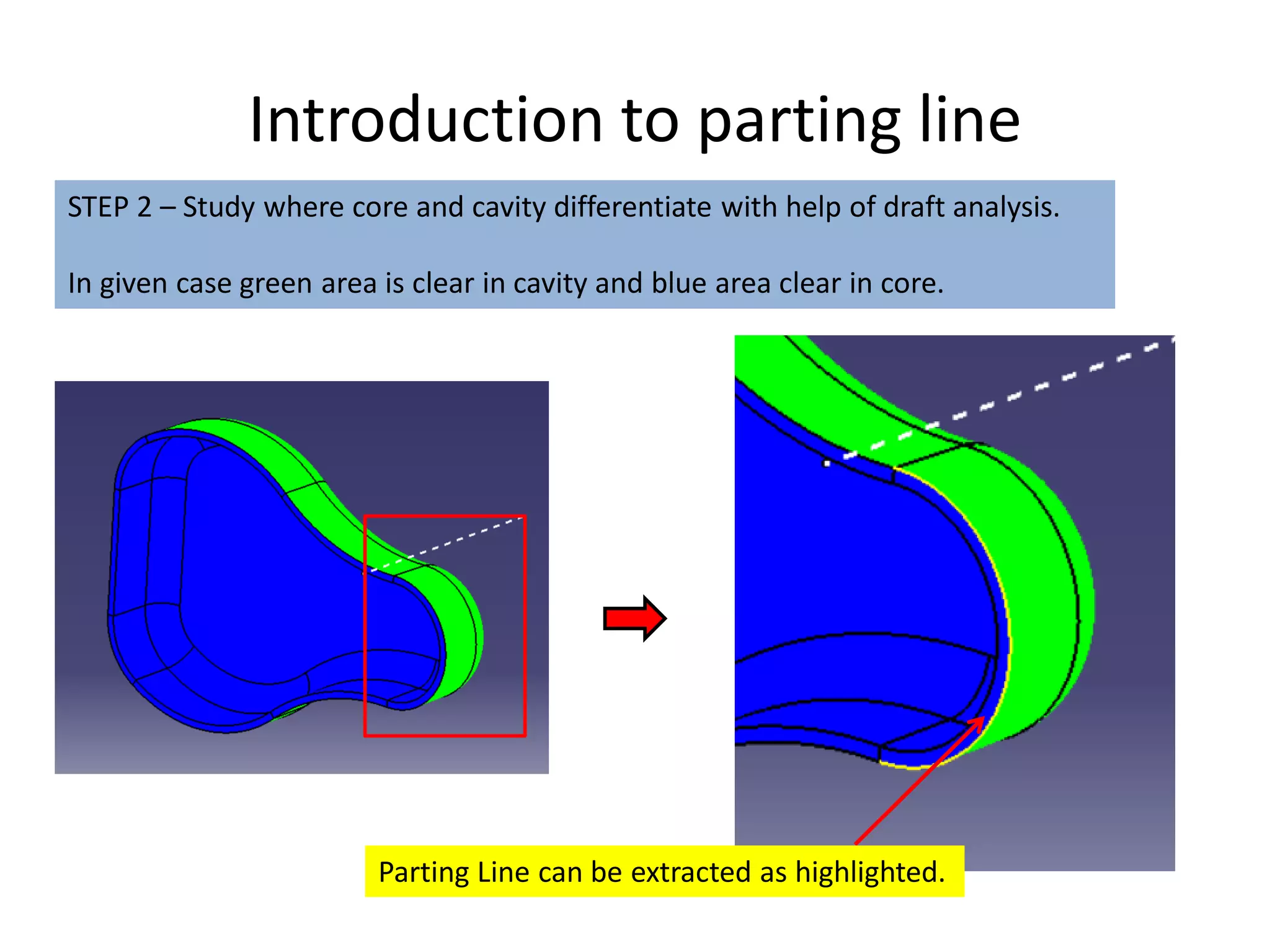

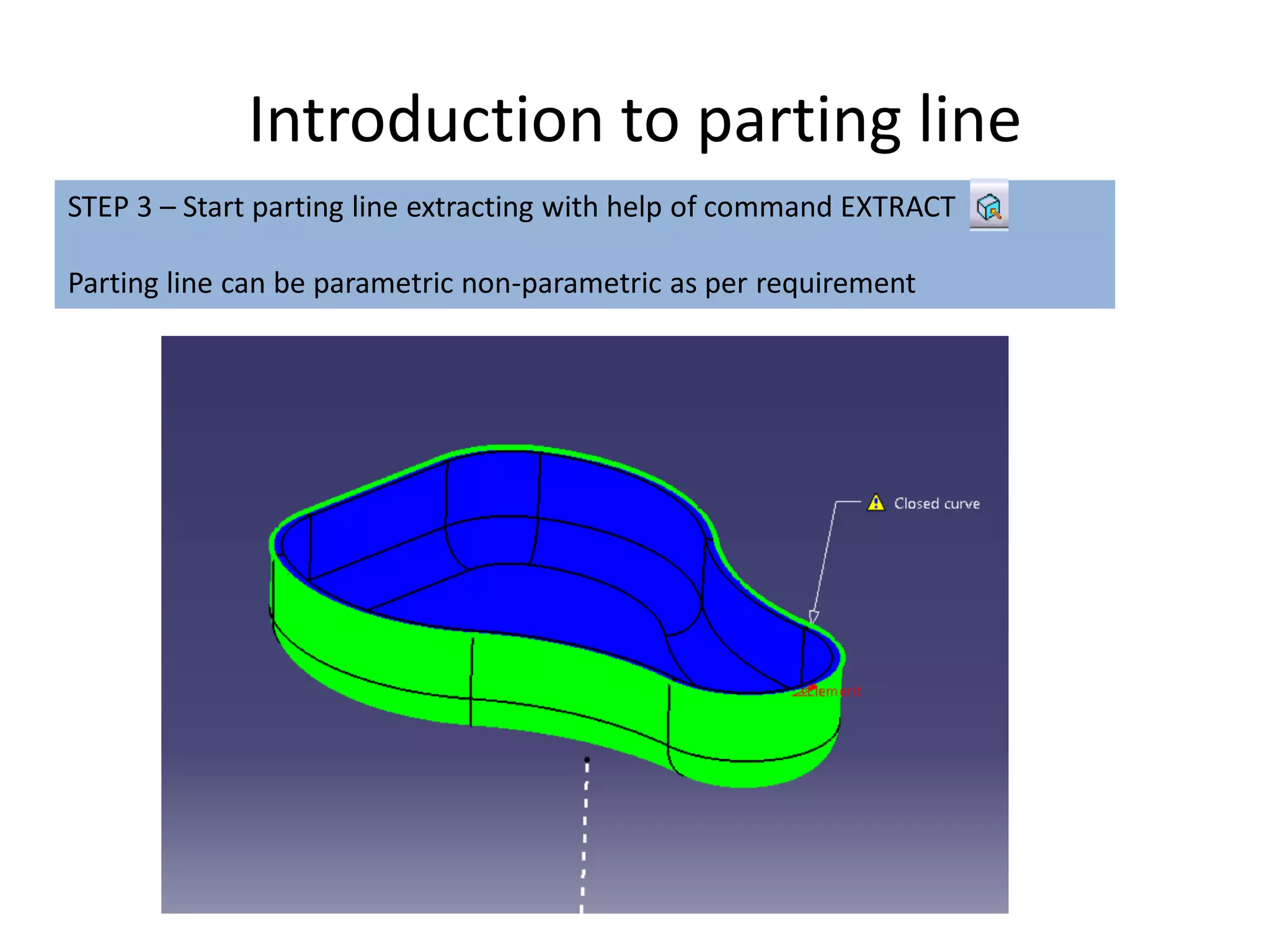

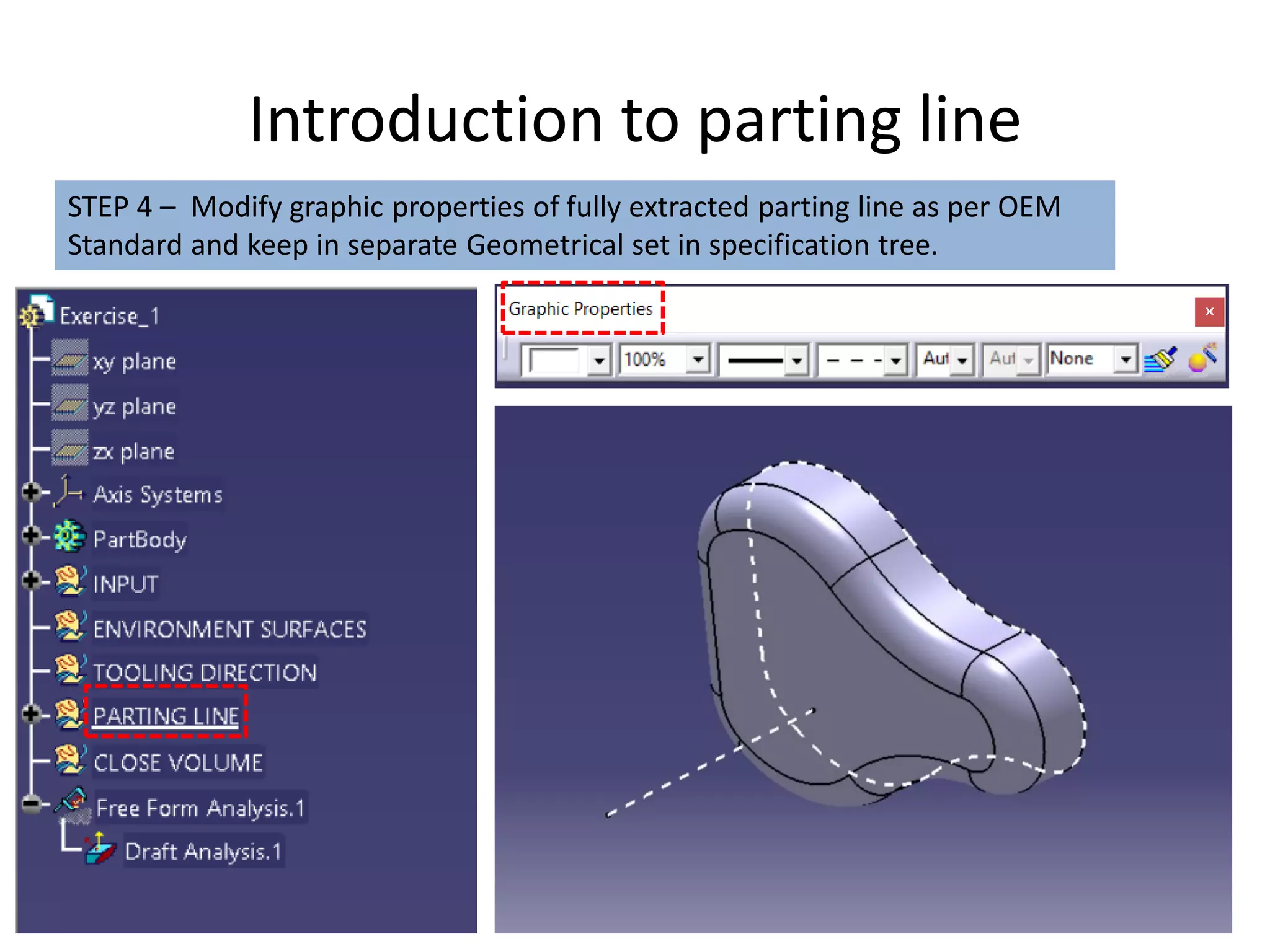

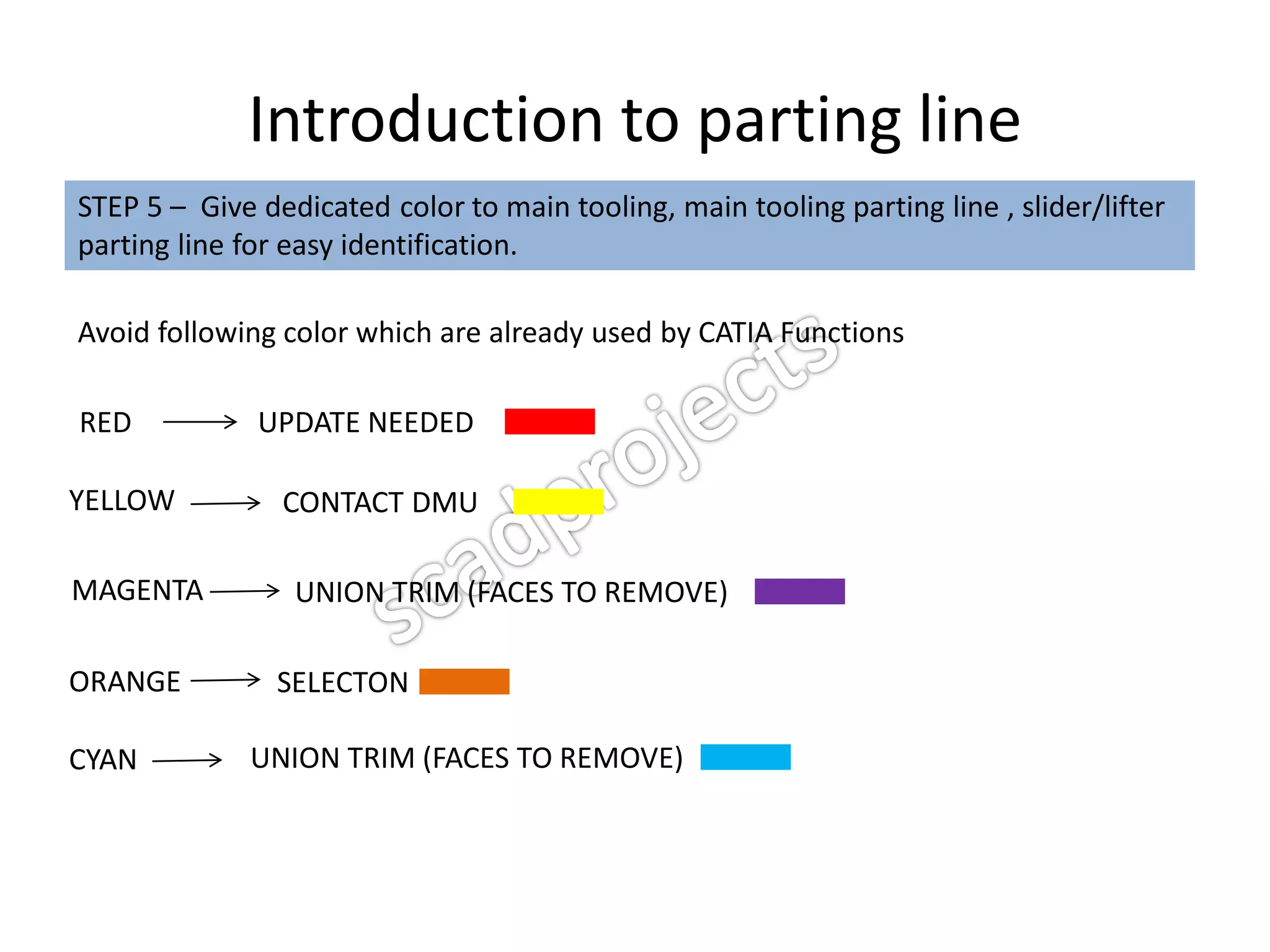

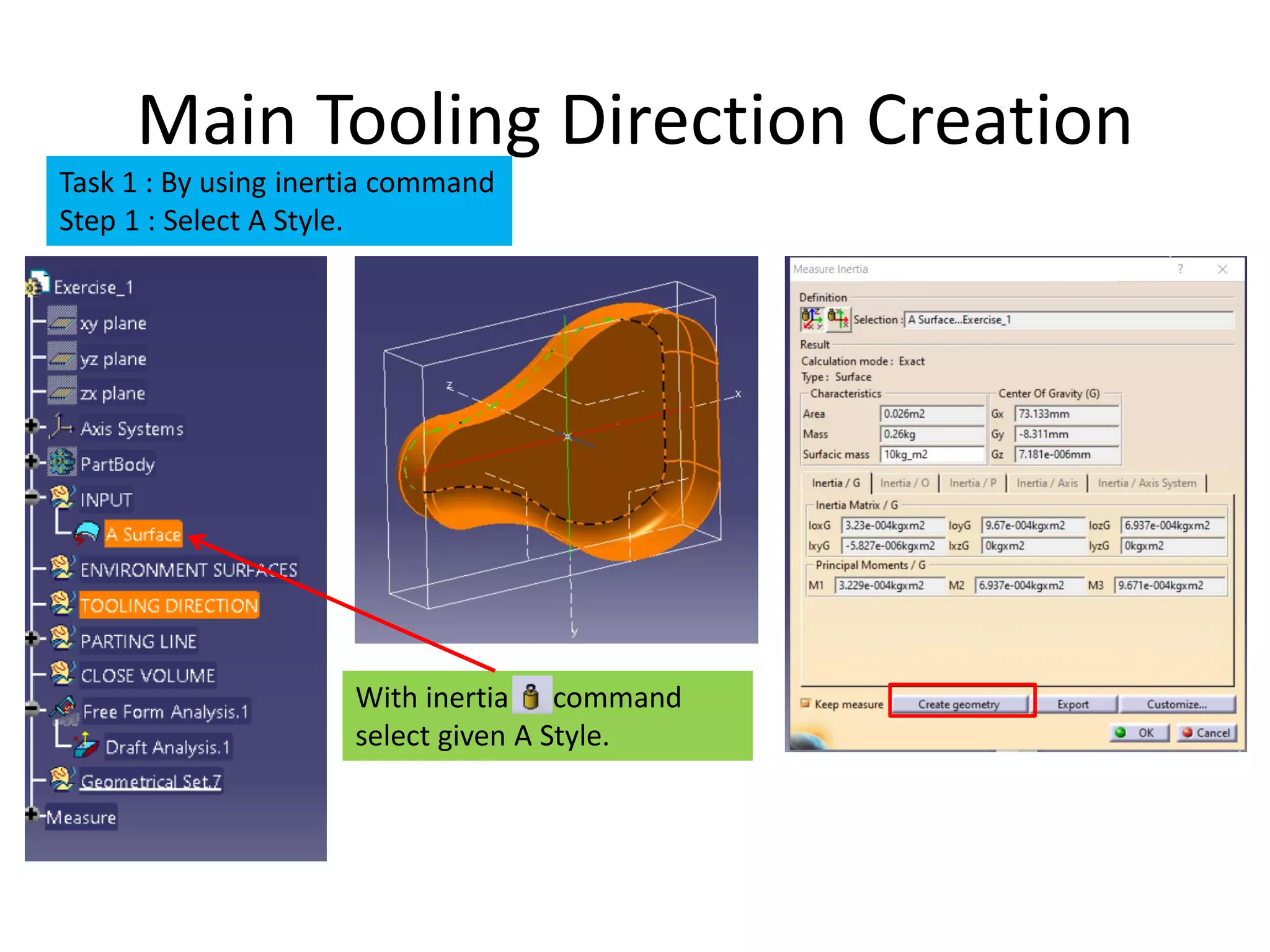

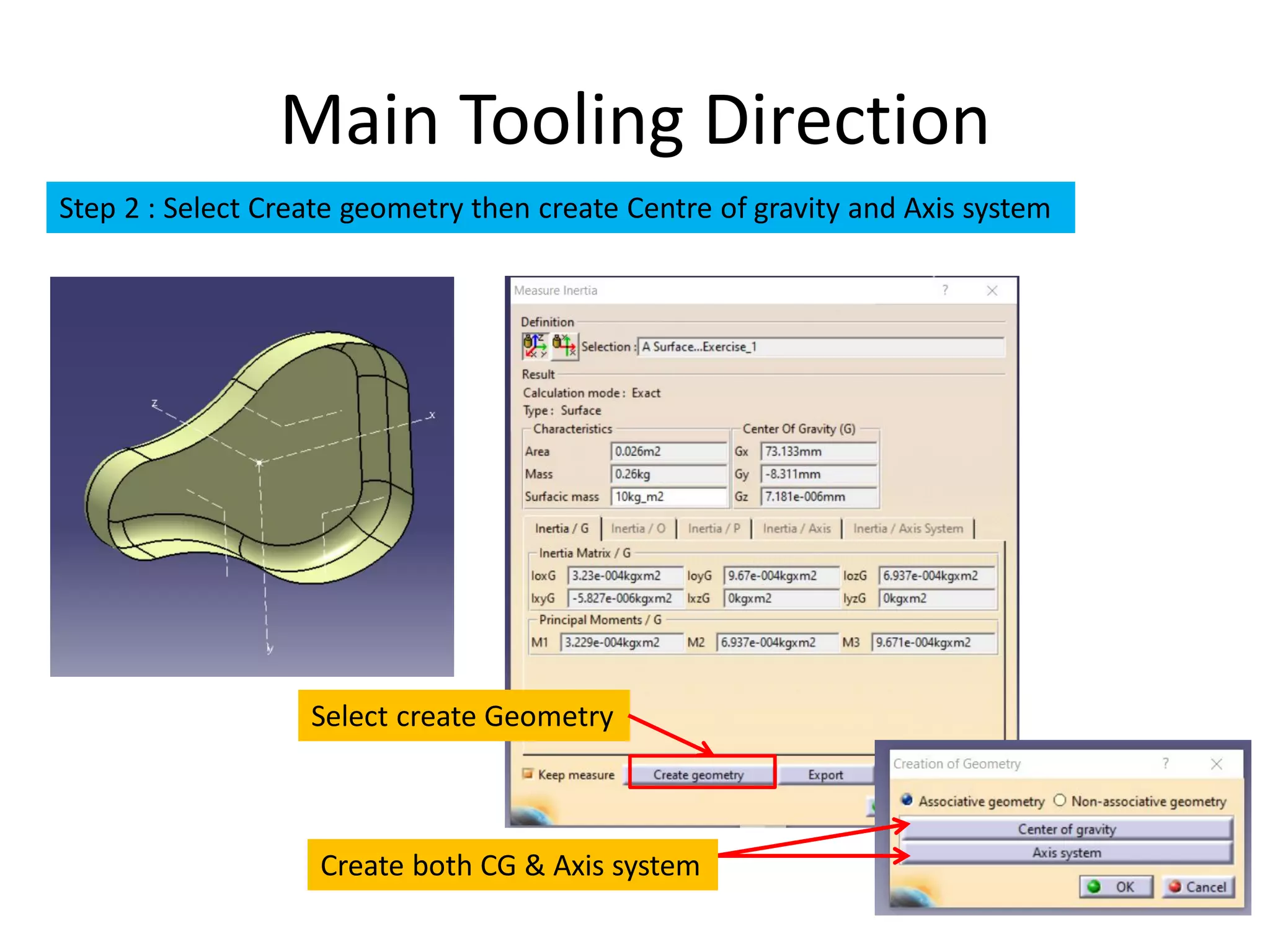

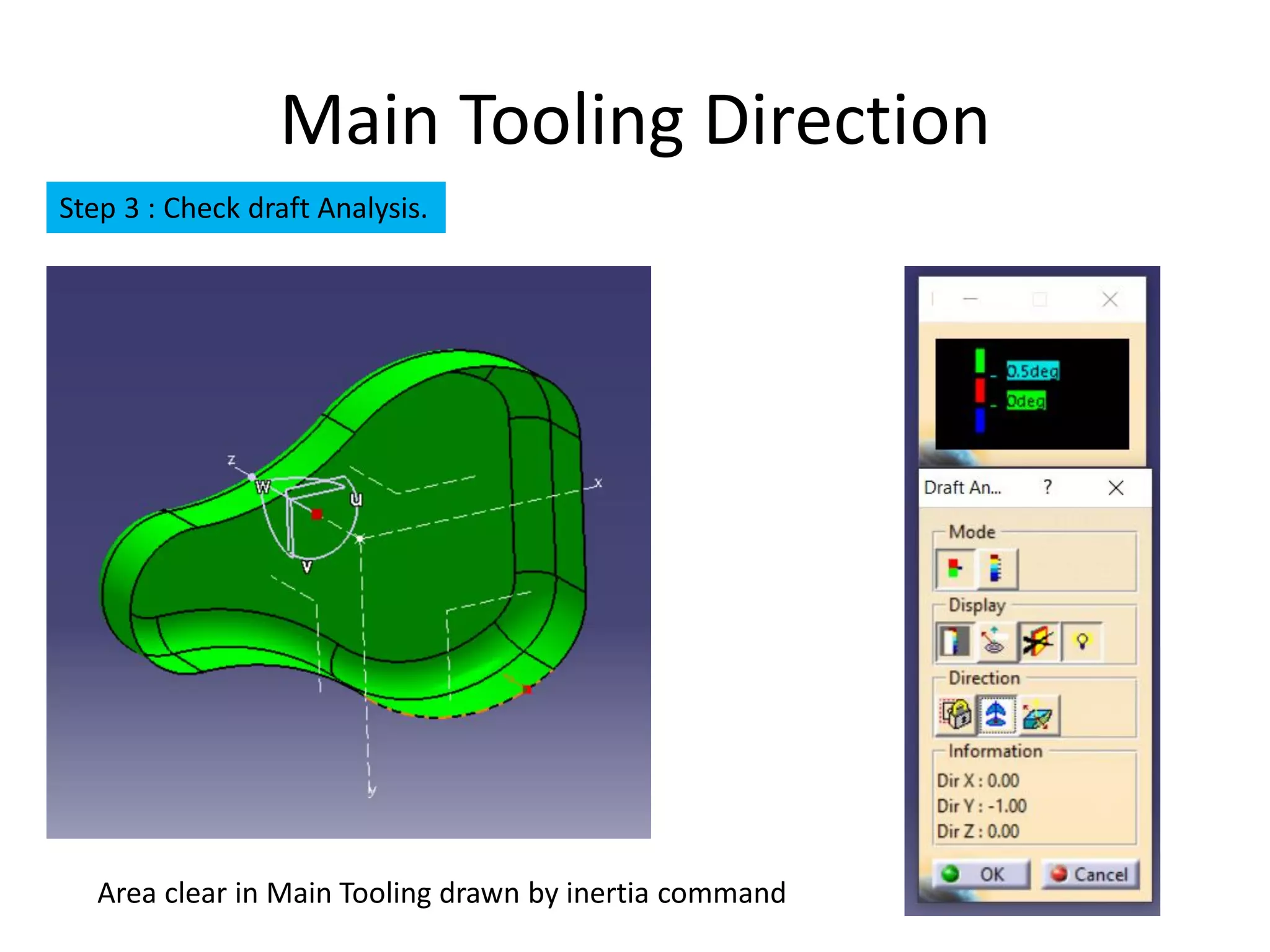

The document provides a comprehensive guide on plastic product design for automotive interior and exterior trims, focusing on draft analysis, main tooling direction, and parting line creation. It outlines the necessary steps and criteria for conducting draft analysis, determining tooling direction, and extracting parting lines using various methods and tools. Key parameters include material modes, feasibility checks, and adherence to OEM standards in the design process.