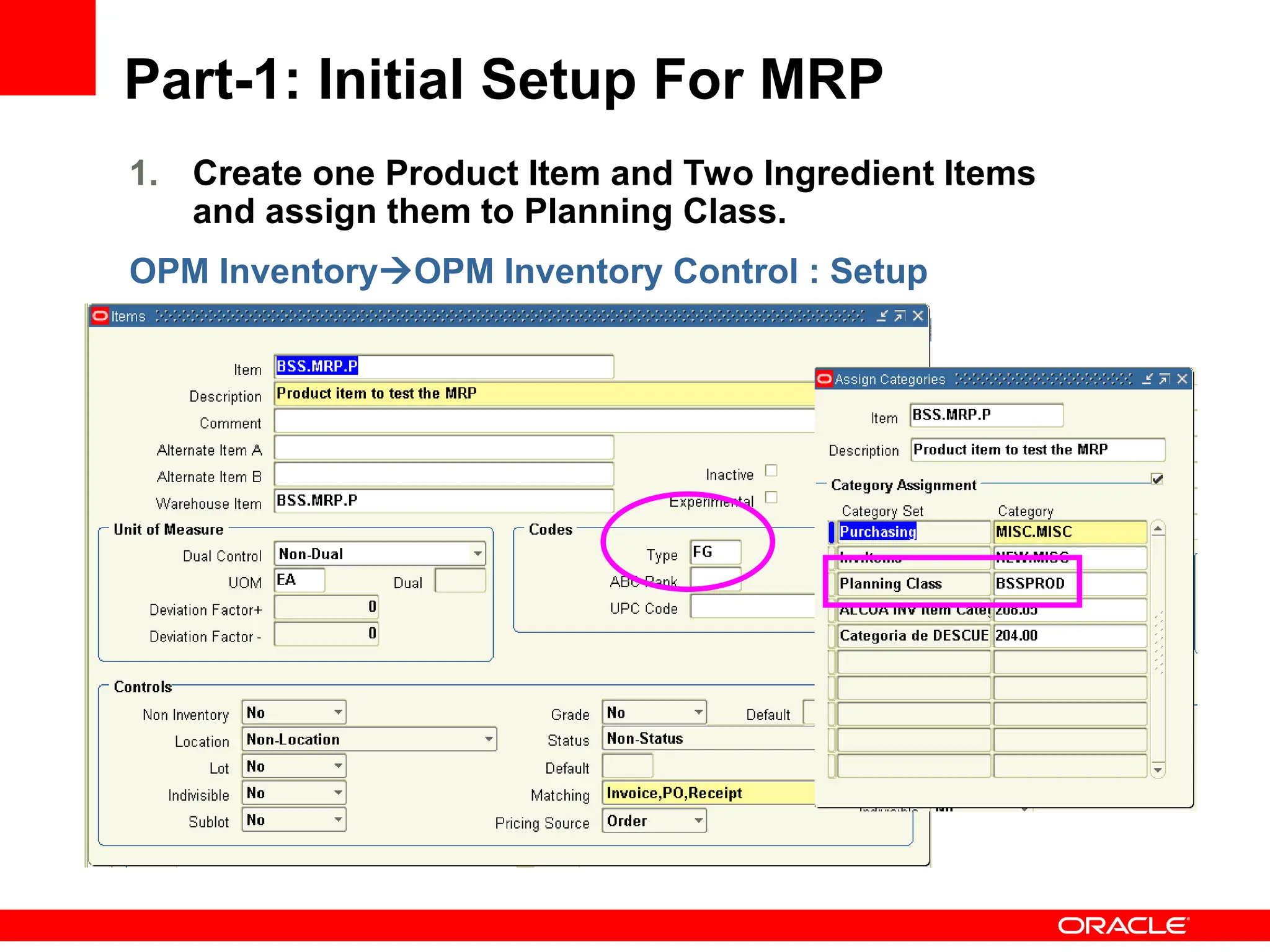

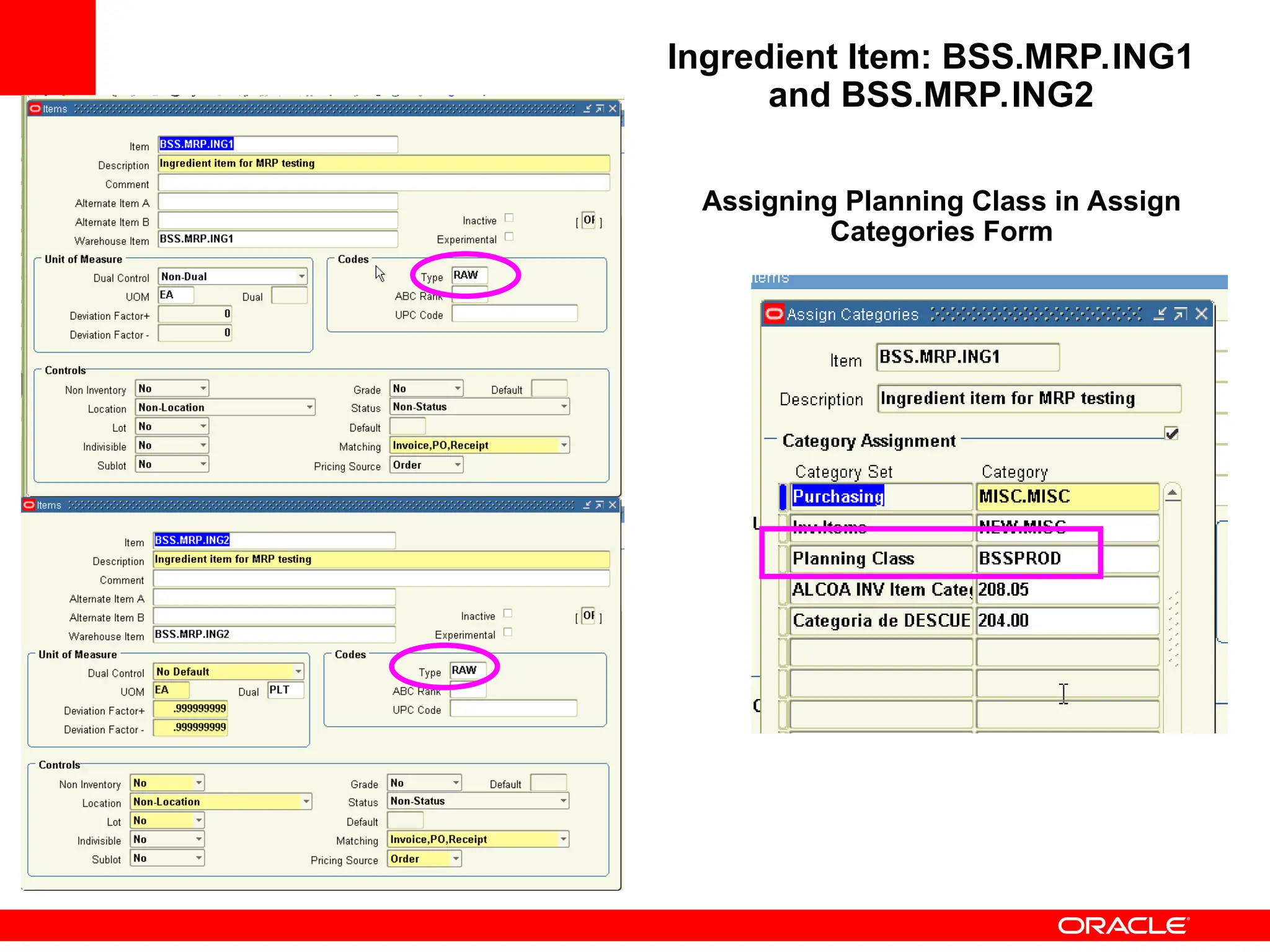

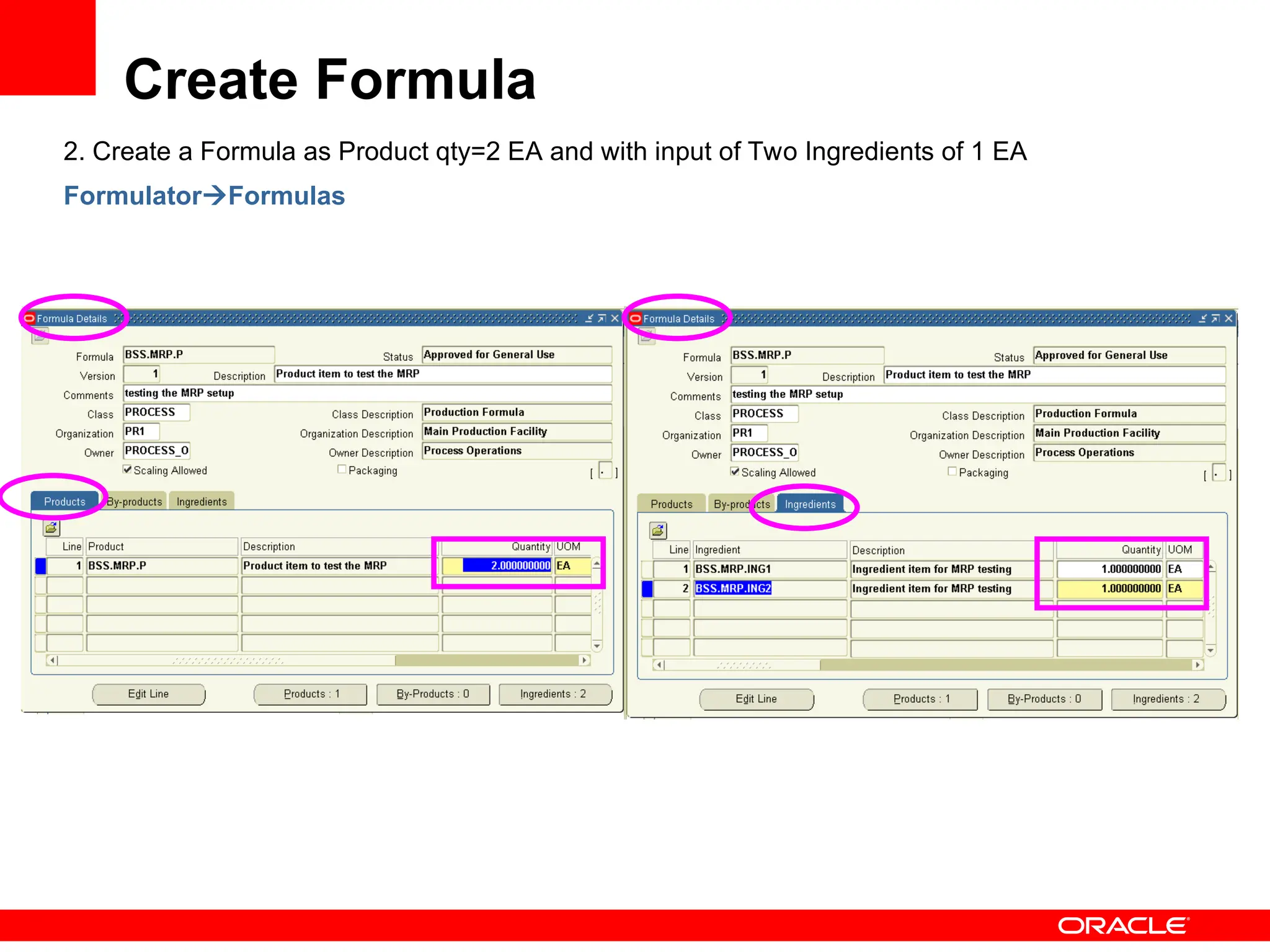

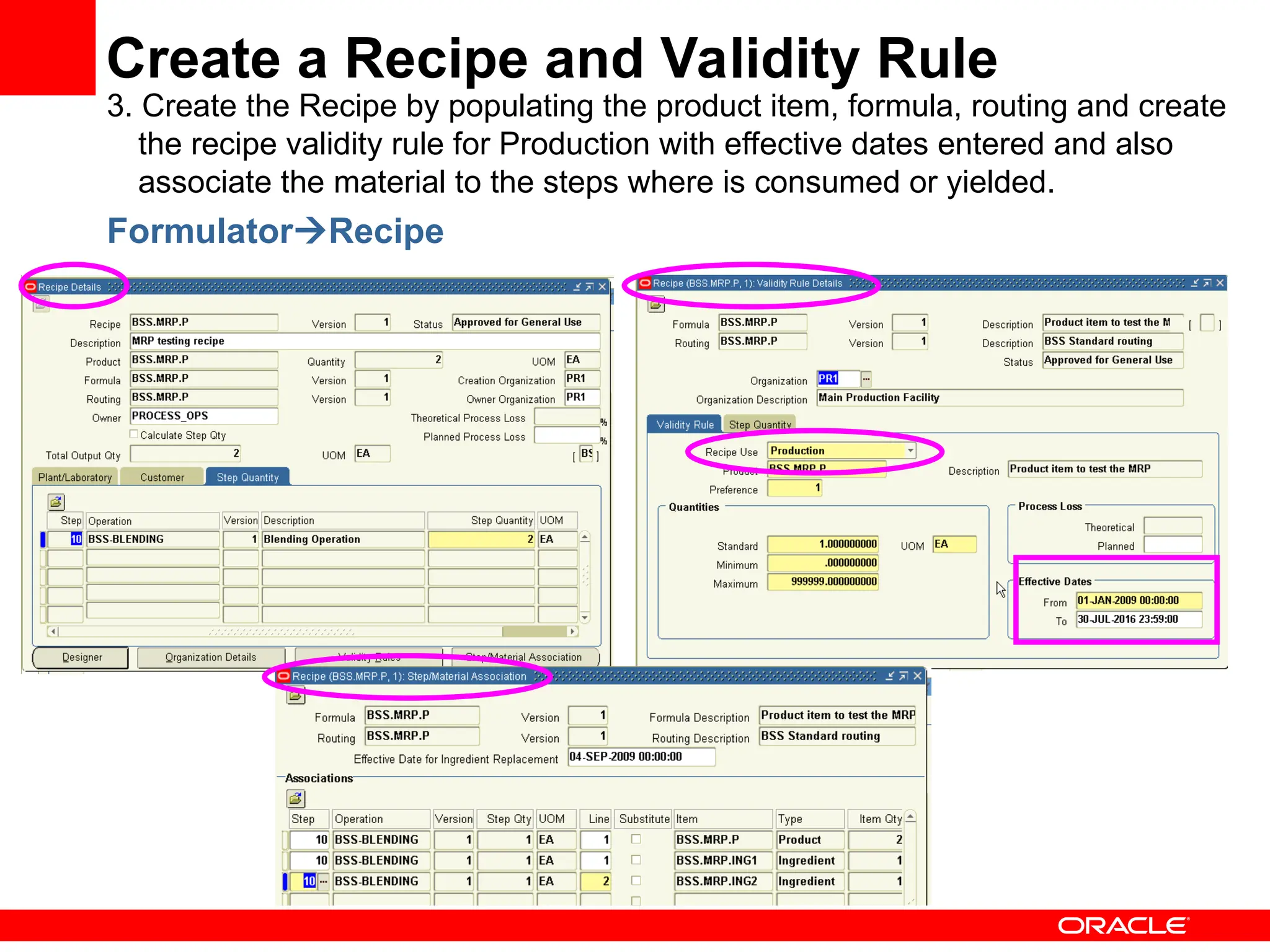

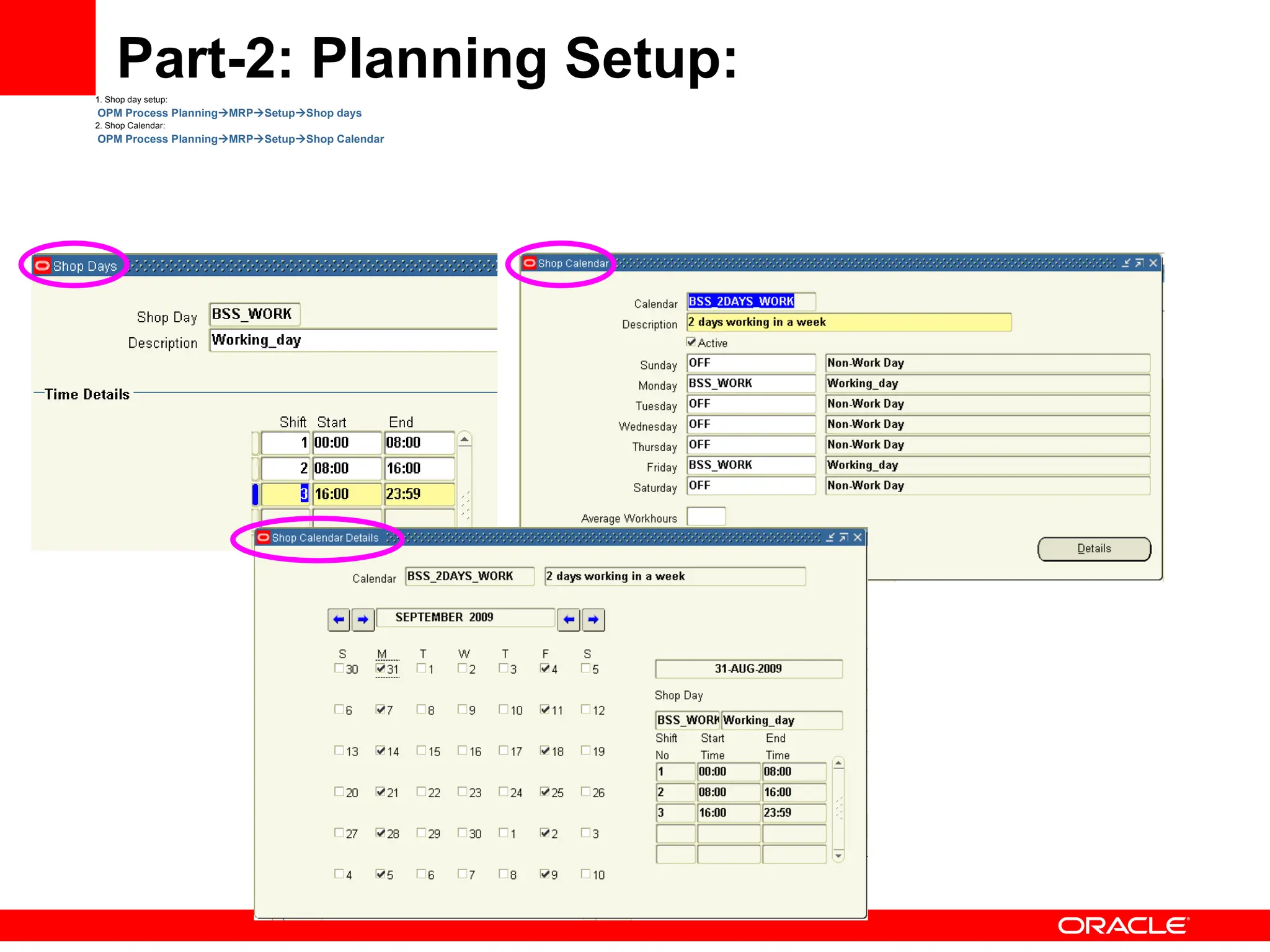

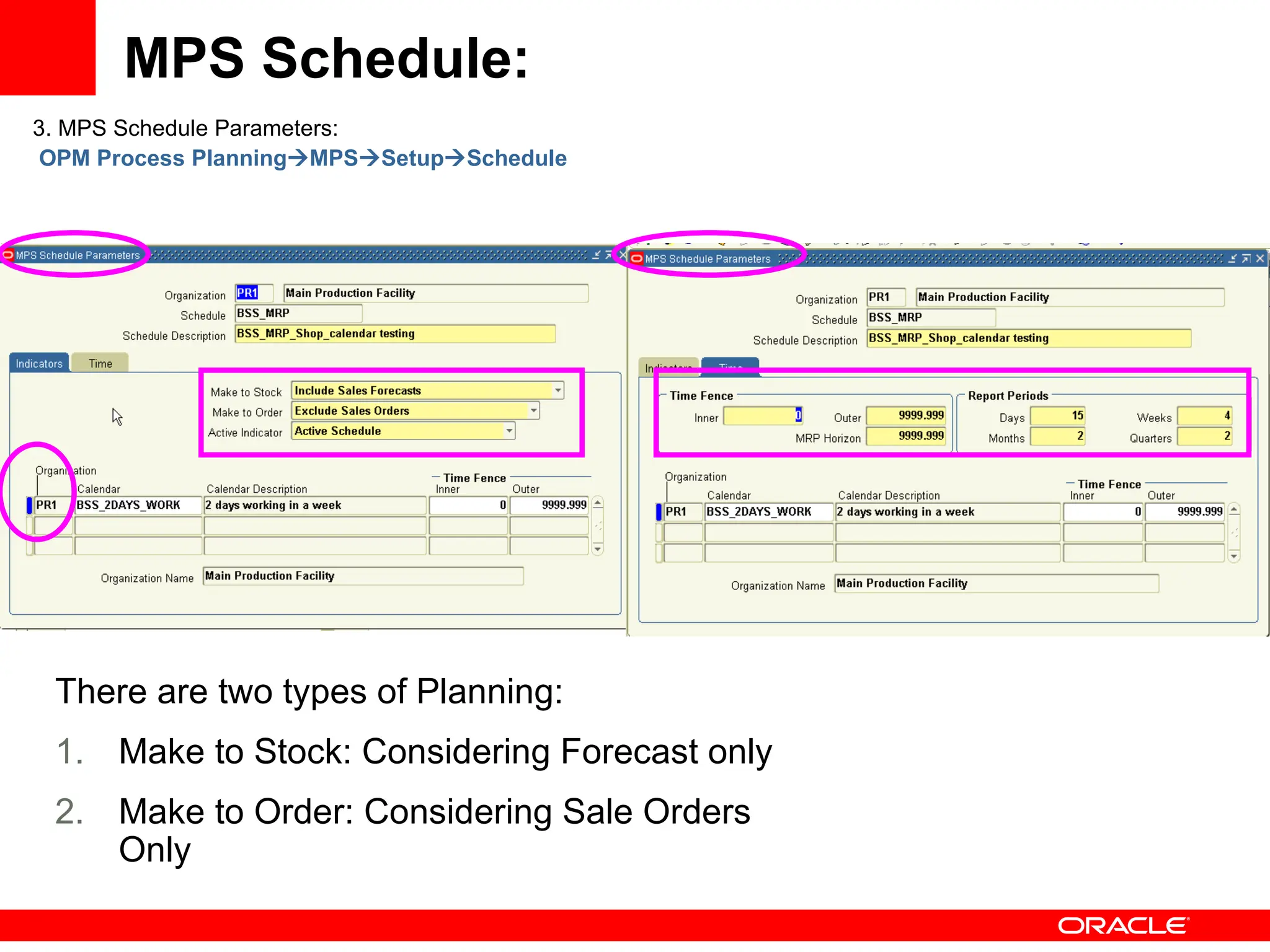

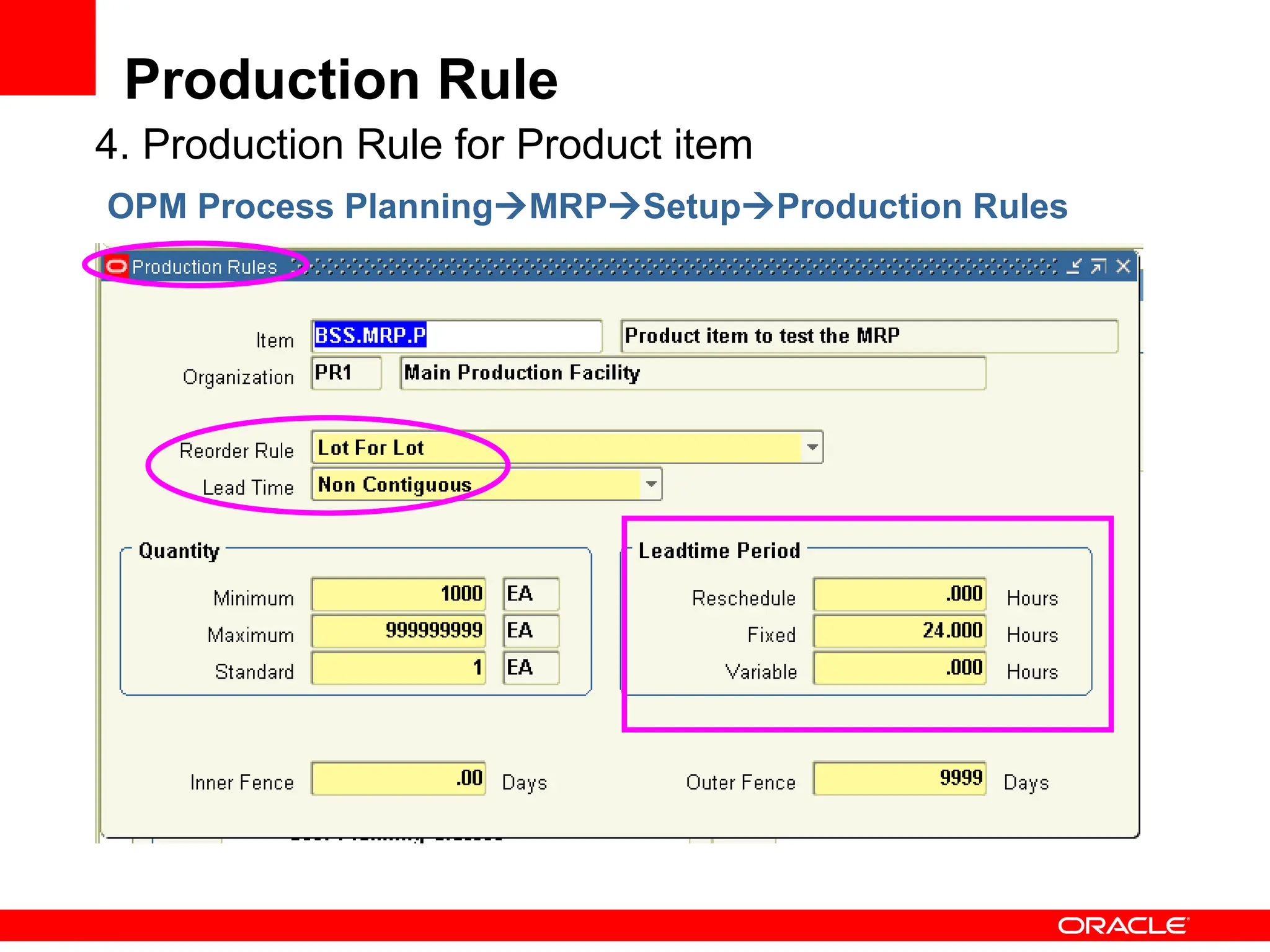

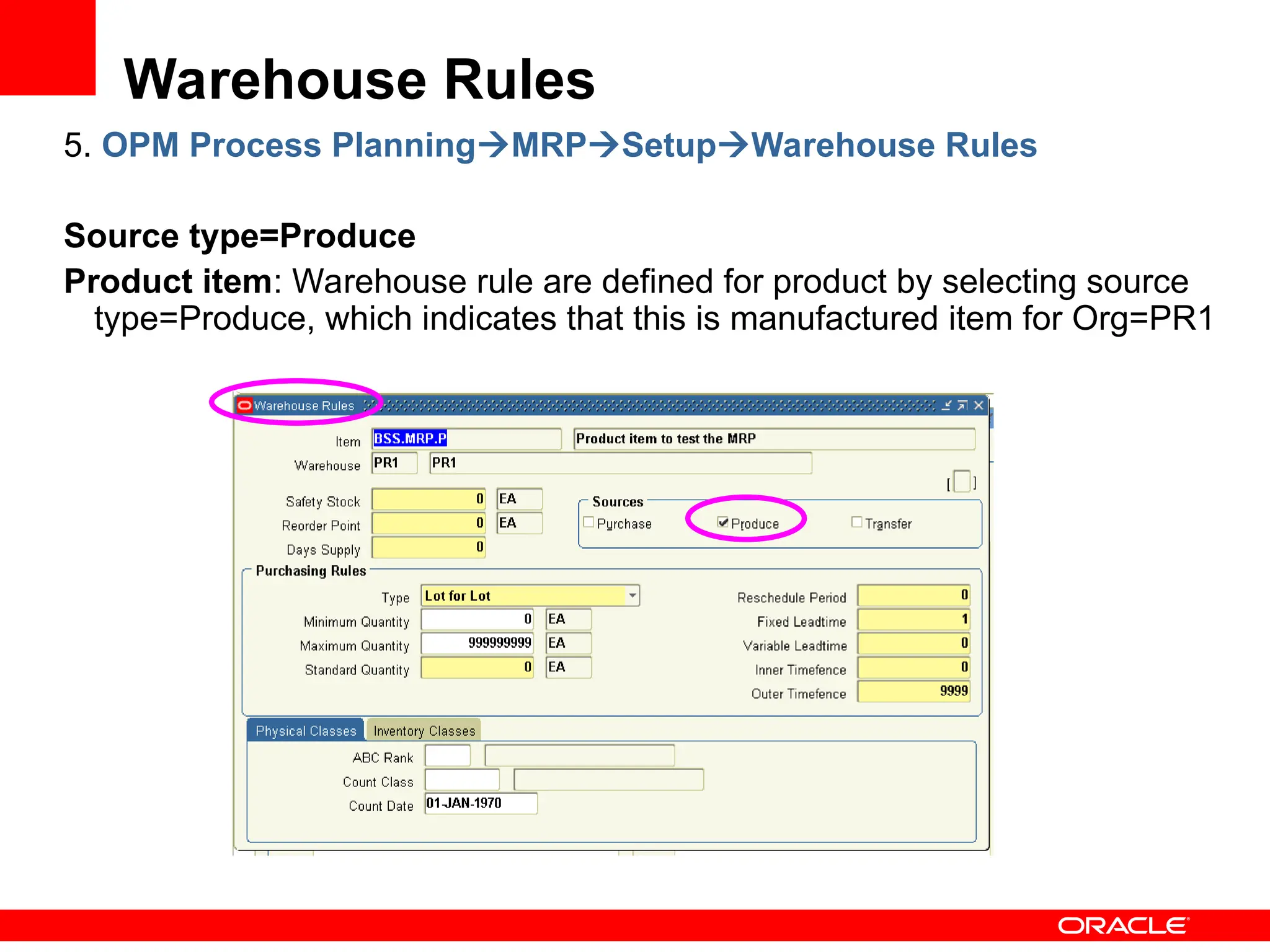

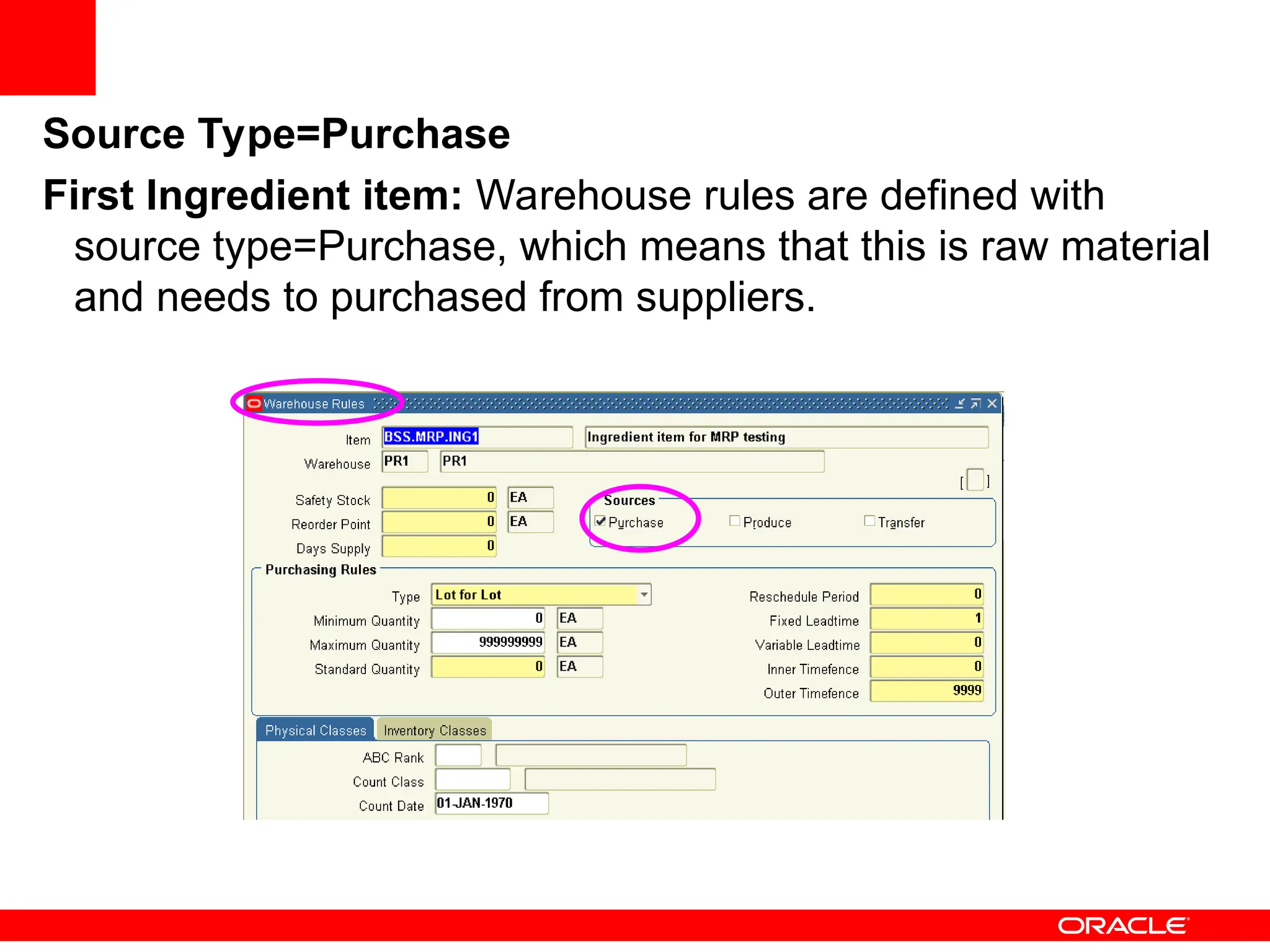

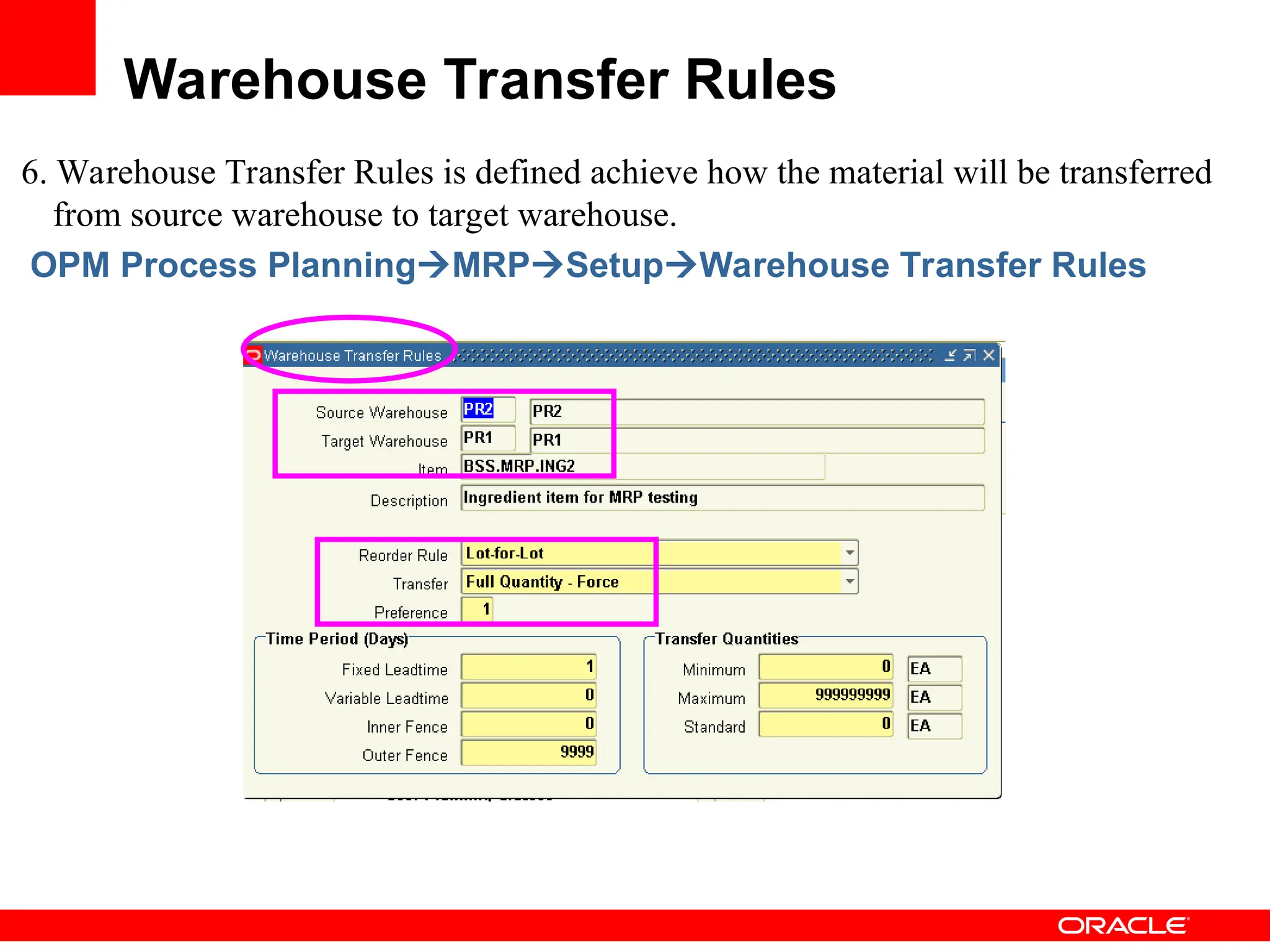

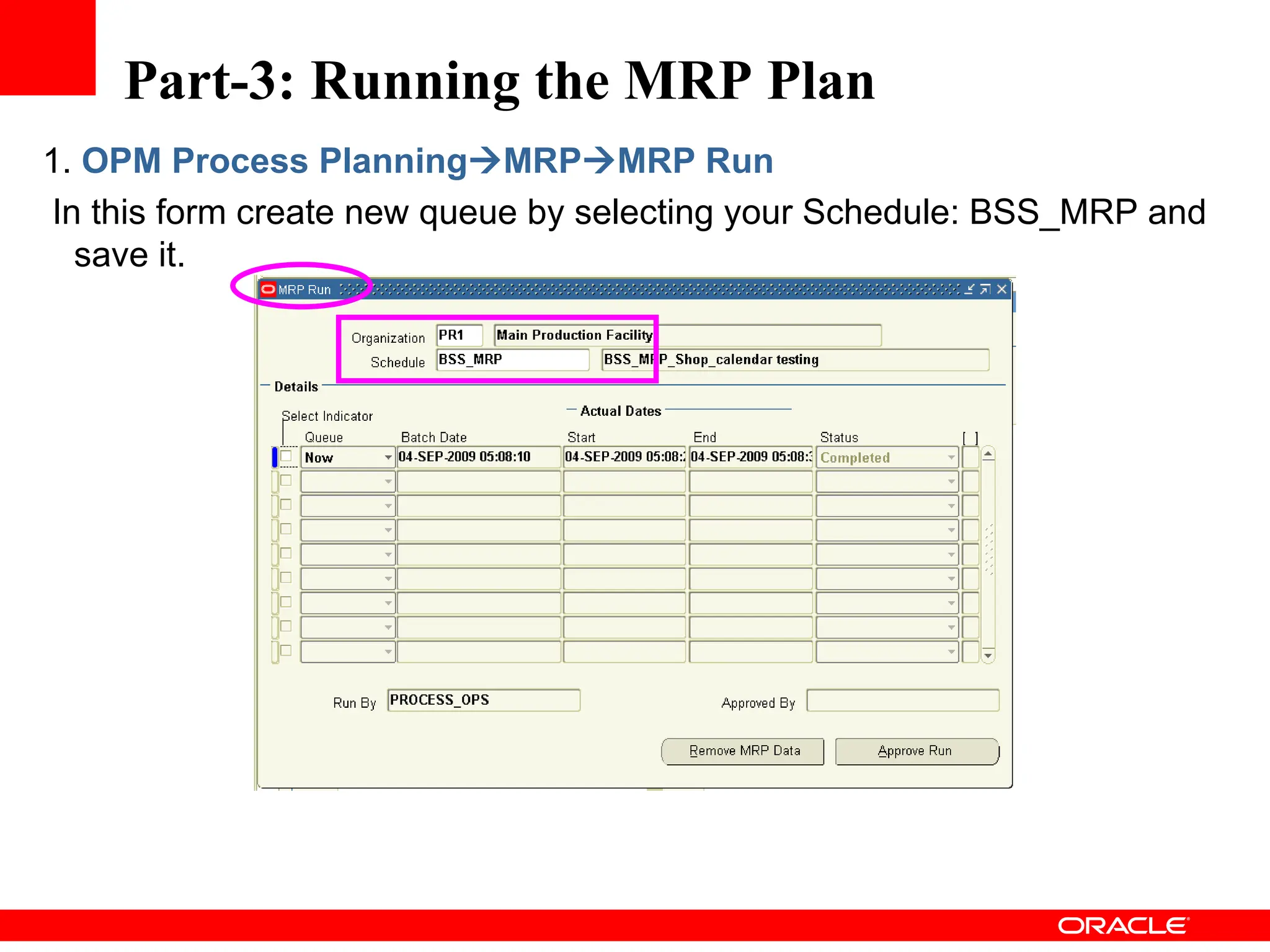

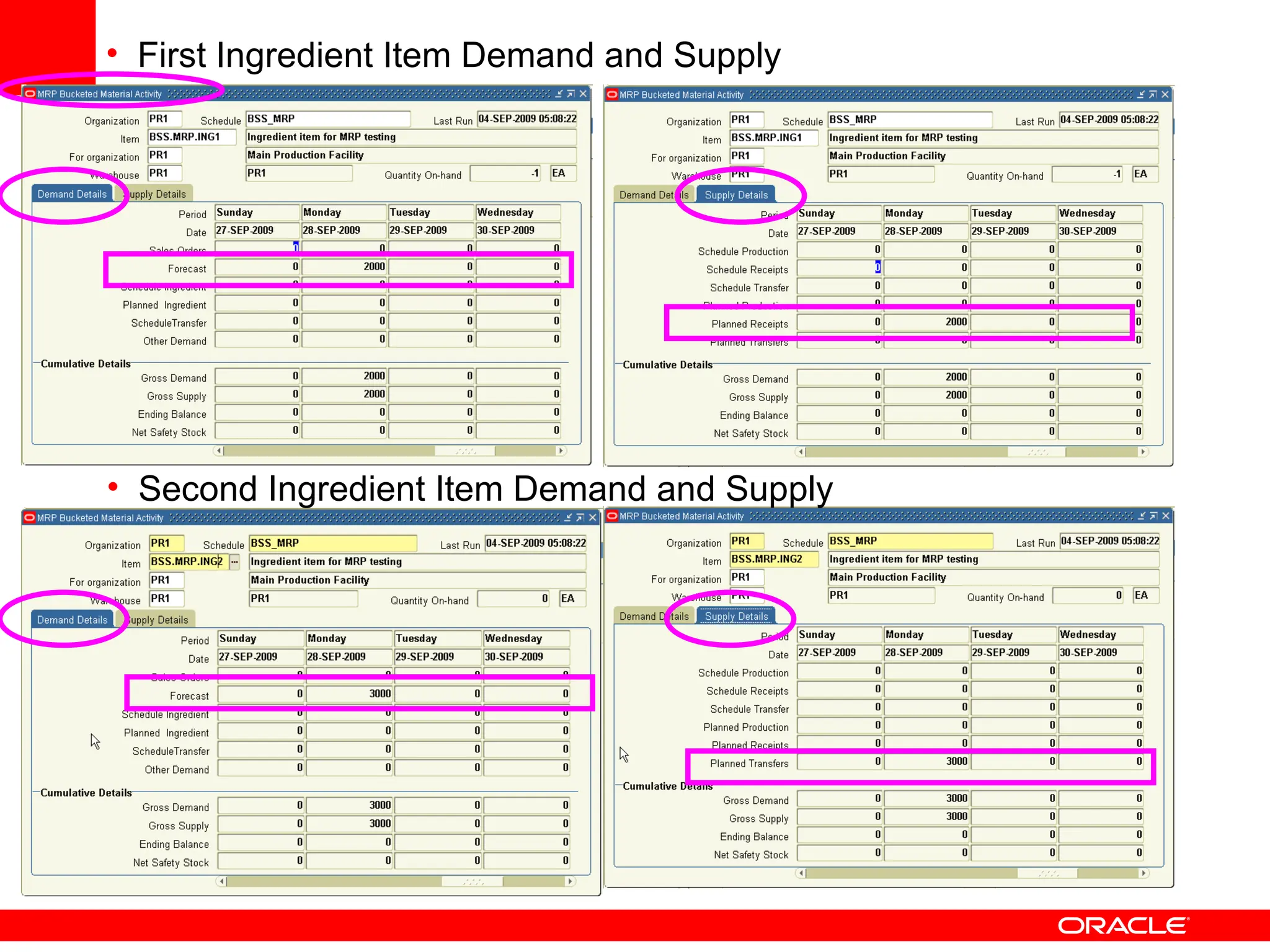

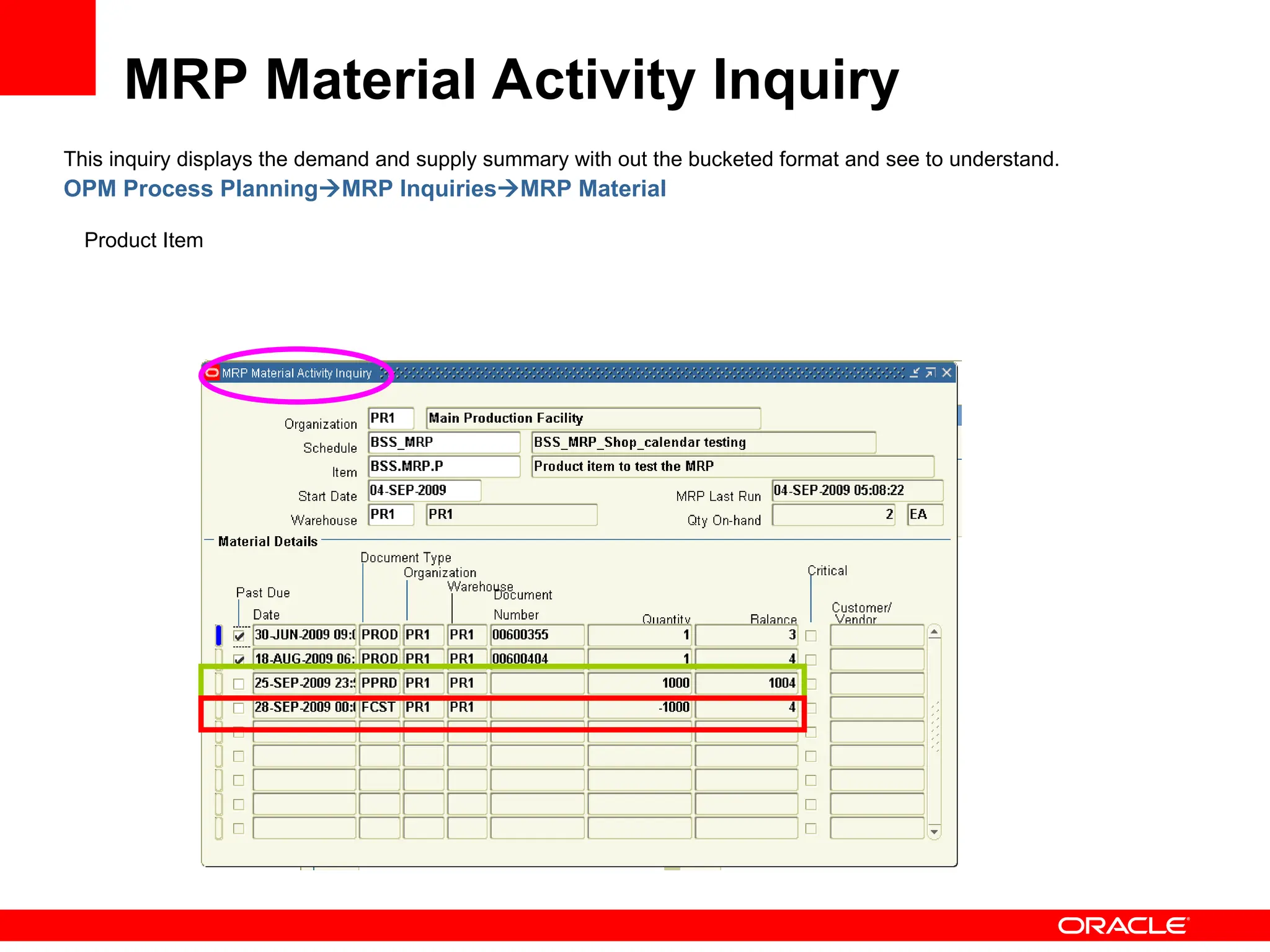

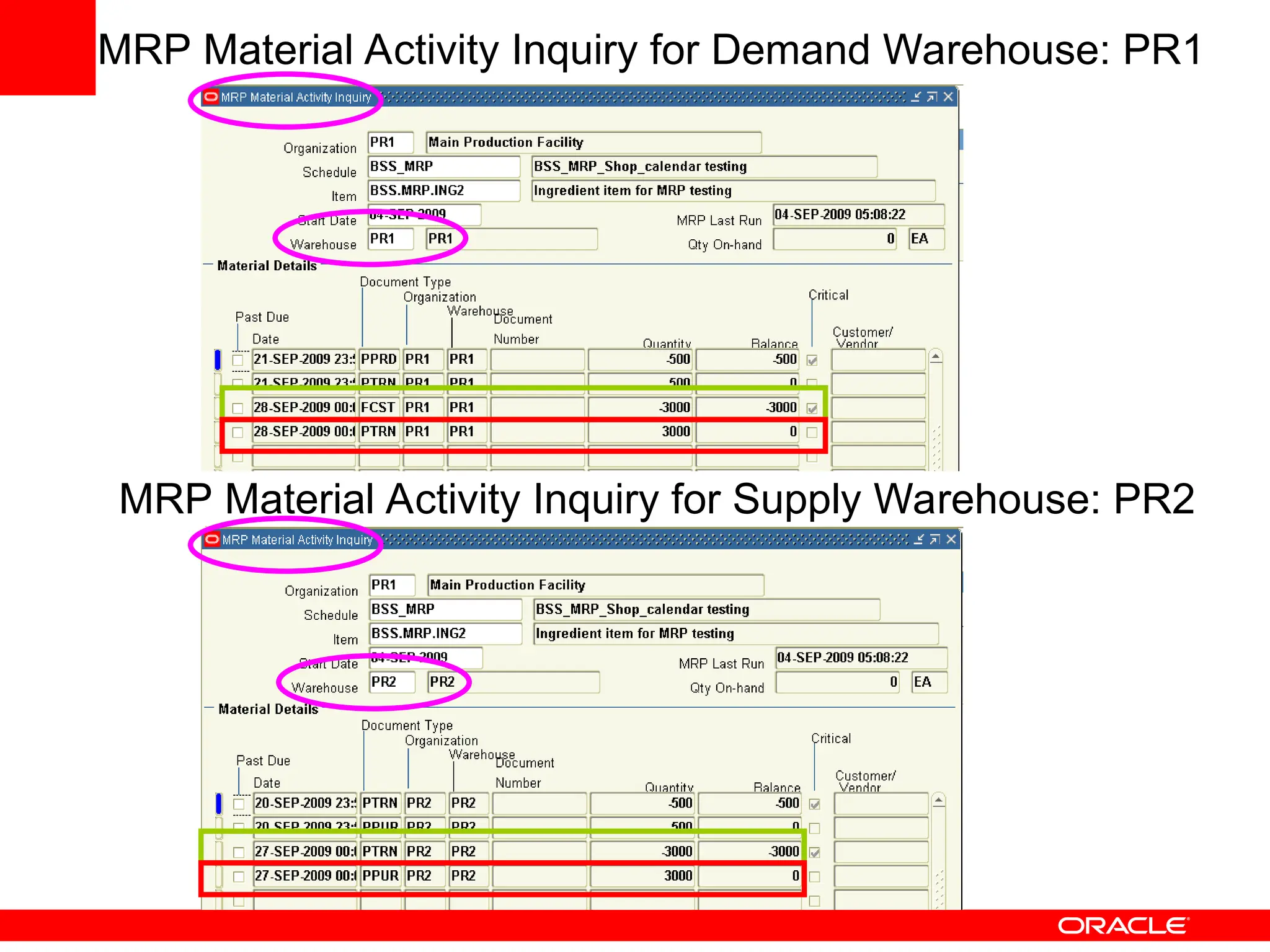

The document outlines the setup and planning processes for Material Requirements Planning (MRP) in an operational process management (OPM) context. It includes instructions for creating product and ingredient items, defining production and warehouse rules, and executing MRP runs while reviewing action messages. The document concludes with a review of demand and supply inquiries and a session for questions and answers.