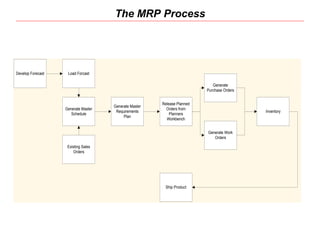

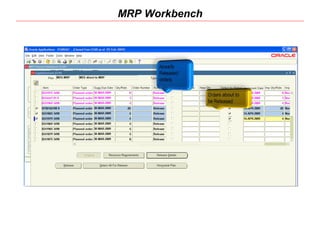

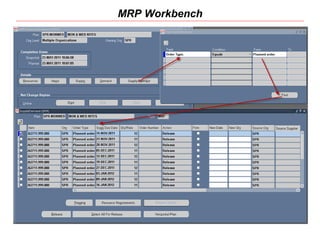

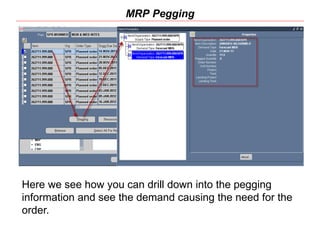

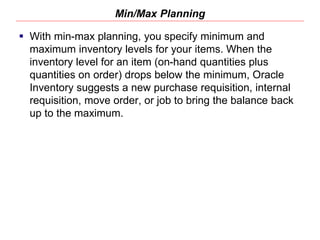

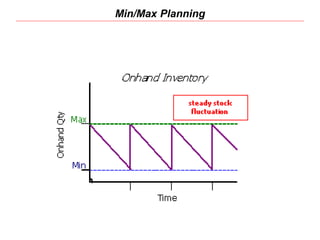

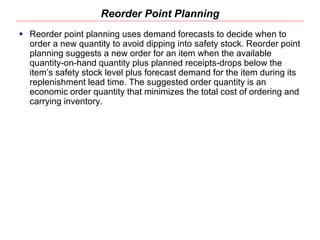

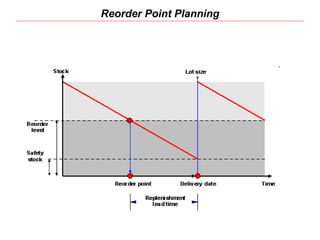

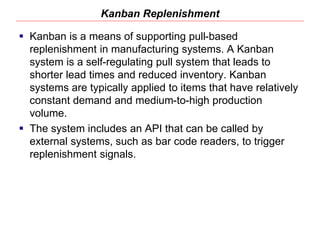

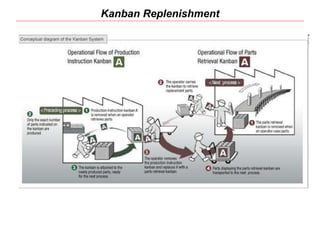

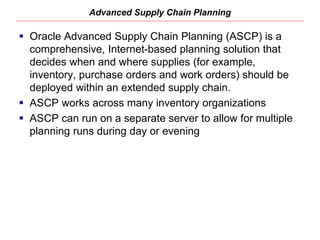

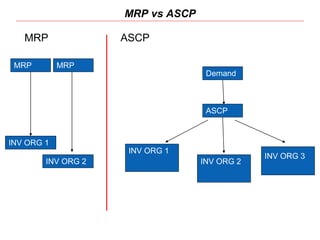

This document provides an overview and guide to Oracle Planning. It begins with an agenda covering the current MRP blueprint, inventory planning options like min-max and reorder point planning, and a demonstration of MRP planning. It then discusses MRP and how it calculates requirements to meet demand. The MRP process and tools like the planner workbench are explained. Alternative planning processes like min-max, reorder point and kanban replenishment are also covered. More advanced planning using Oracle Advanced Supply Chain Planning is described.