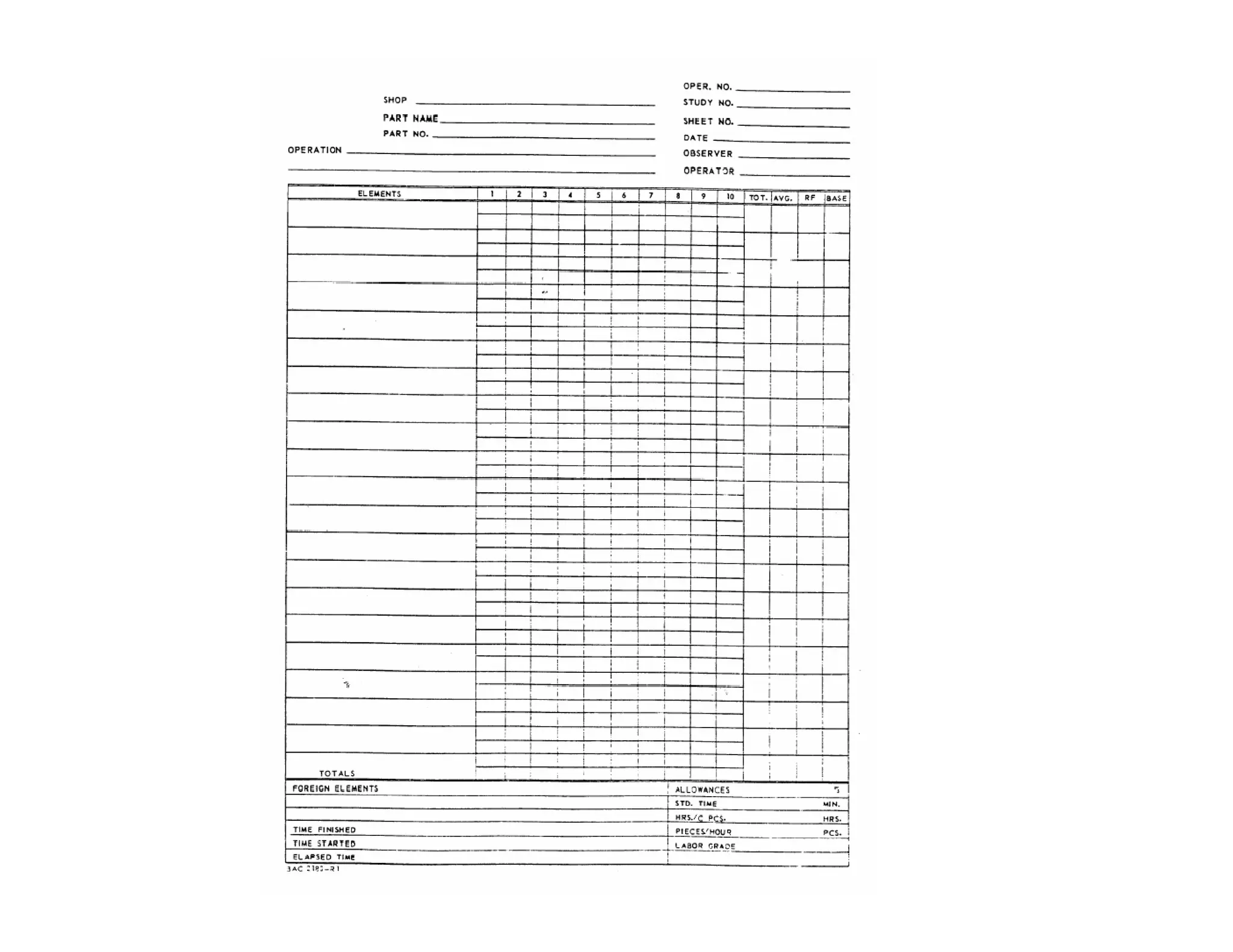

This document discusses concepts related to motion and time study in industrial engineering. It describes the goals of motion study as improvement, planning, and safety. Time study techniques like time and motion study and work sampling are used to determine how long tasks take and how workers spend their time. The learning curve concept shows that as workers gain experience, the time it takes them to complete repetitive tasks decreases according to a predictable formula. Frederick Taylor's pioneering time and motion studies from the 1900s are also summarized.