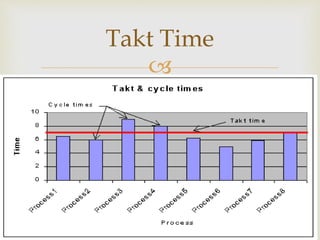

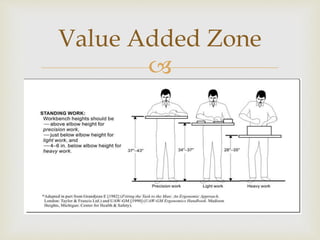

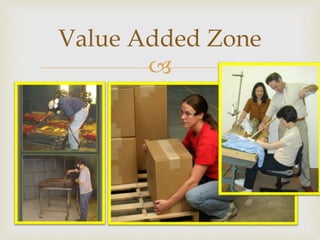

The document discusses time measurement and defines key terms. It aims to identify the time needed to perform processes, time for each process element, and fluctuations due to problems. Reasons for time measurement include process instabilities, deviations from standards, inadequate tools, lack of training, and equipment failures. The document defines time measurement, time study, and takt time. It discusses value and non-value added activities, and defines the value added zone.