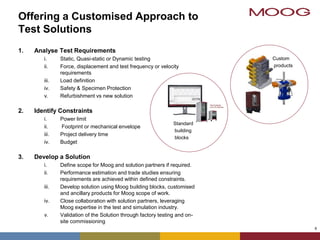

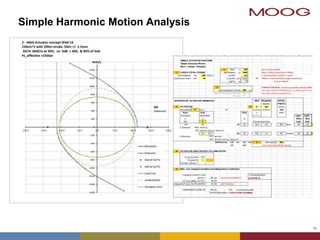

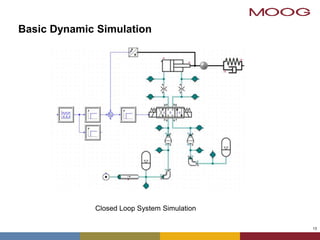

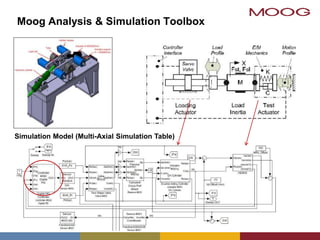

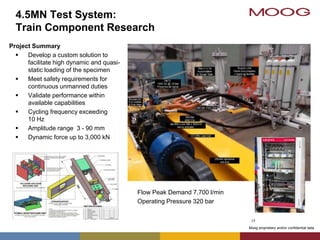

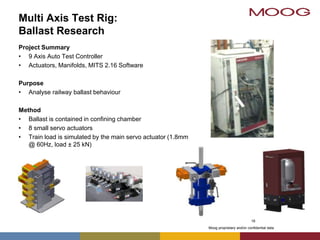

Moog specializes in providing customized testing solutions across various industries, including aerospace, automotive, and industrial applications, maximizing the value for testing labs through performance estimations and cost/performance trade studies. Their offerings include advanced servo-hydraulic actuators, hydraulic power units, and simulation tools designed to meet specific requirements within defined constraints. Moog also emphasizes collaboration with partners and global support to deliver comprehensive testing systems.