The document discusses various topics related to pumps used in process industries including:

- The main types of pumps used are centrifugal, reciprocating, rotary, and sealless pumps. Centrifugal pumps are most commonly used.

- Pump selection depends on the required head-capacity and properties of the fluid handled. Centrifugal pumps are generally preferred.

- Detailed calculations must be performed by the process engineer to determine pump parameters like discharge pressure, NPSH available, power requirement, etc.

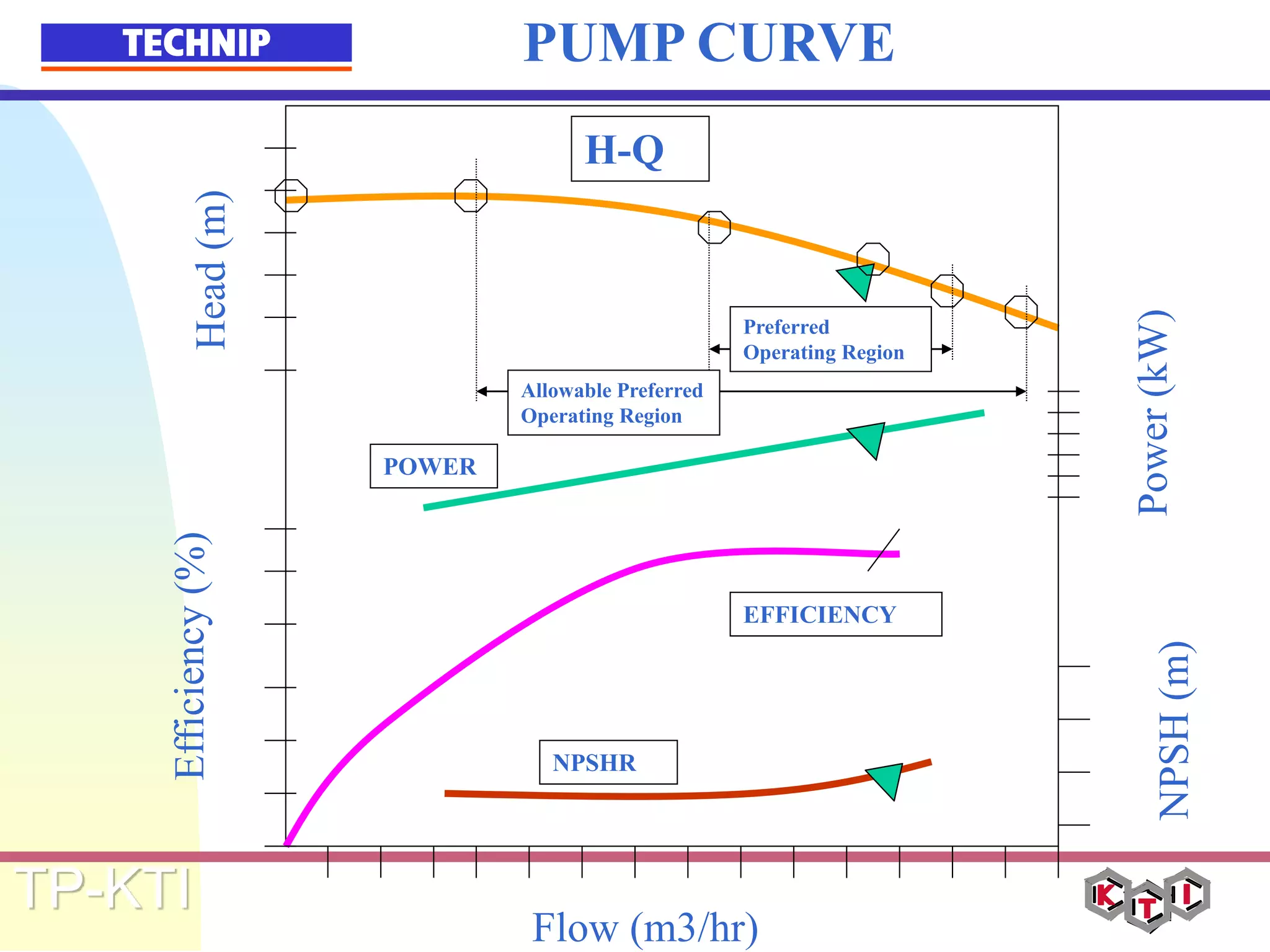

- Characteristic curves provided by vendors are used to select the duty point where the pump will operate most efficiently.

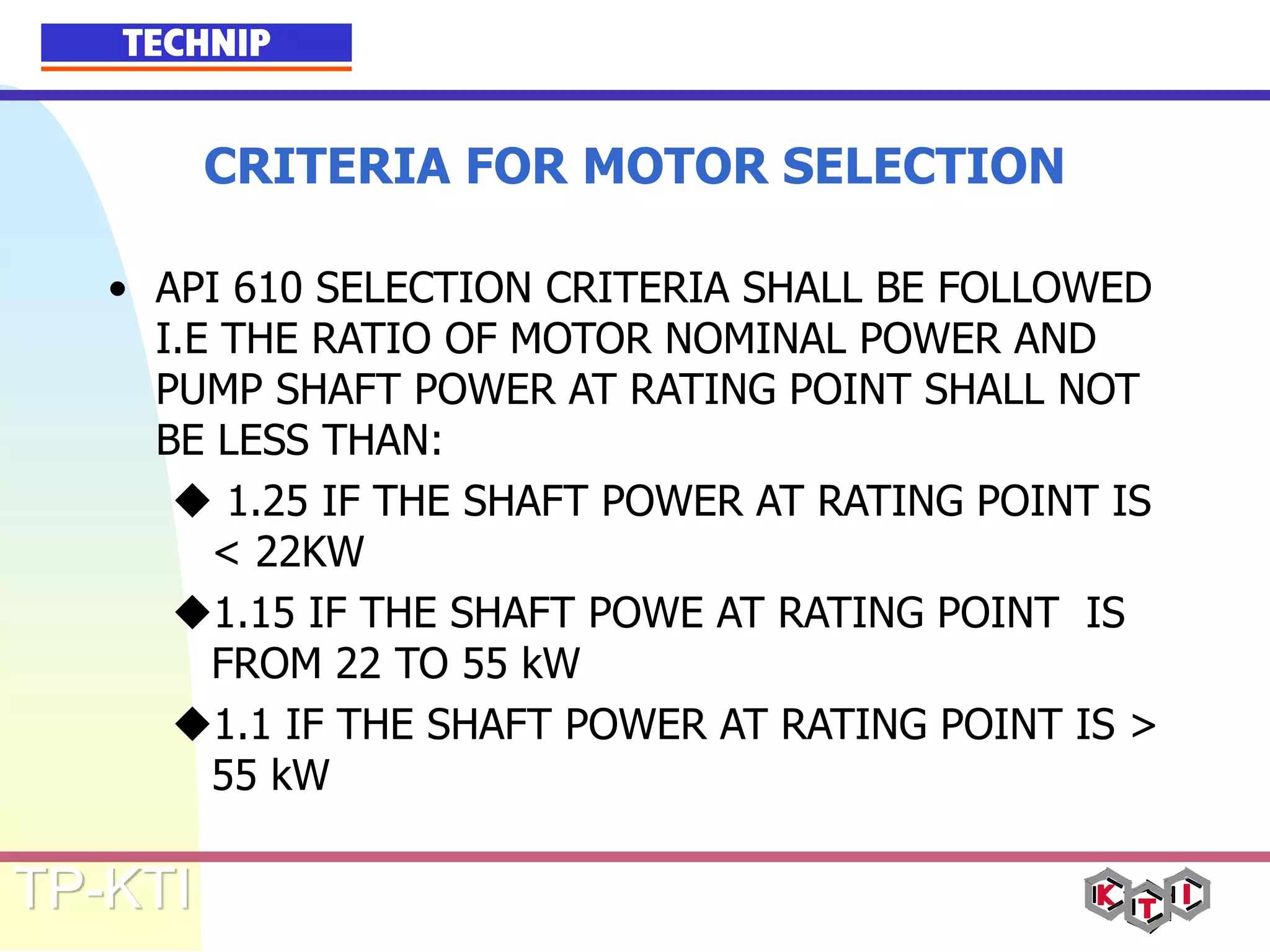

- Other topics covered include standards, materials, drivers, sealing, parallel operation, and process data