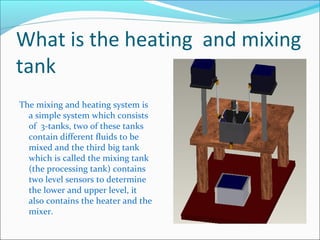

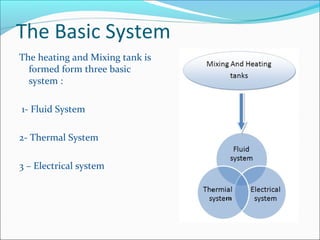

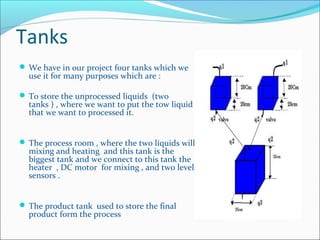

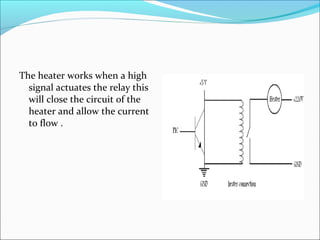

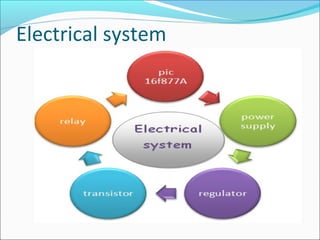

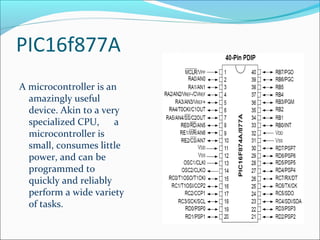

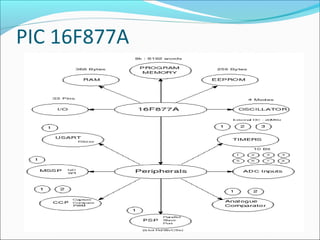

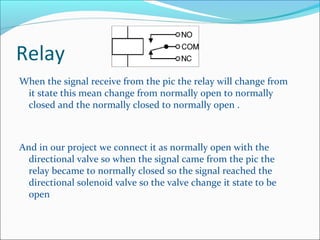

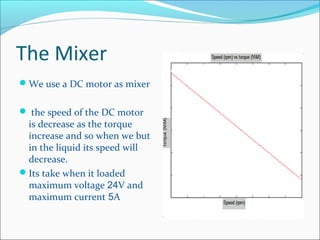

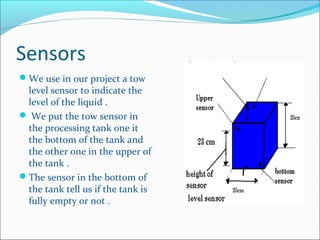

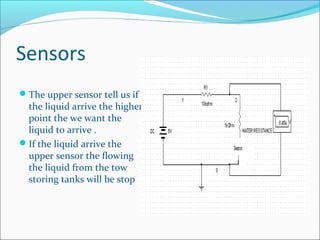

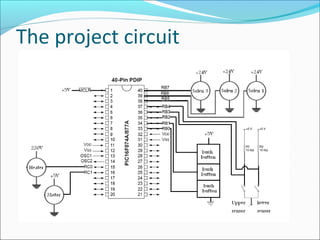

The document outlines a mechatronics project involving a heating and mixing tank system composed of three tanks for fluid storage, processing, and product storage, along with a heater and mixer controlled by a microcontroller (PIC16F877A). It describes the fluid system including solenoid valves, thermal system with heating capabilities, and the electrical system with sensors for monitoring liquid levels. The project aims to efficiently mix and heat liquids while ensuring proper control and automation through various electronic components.