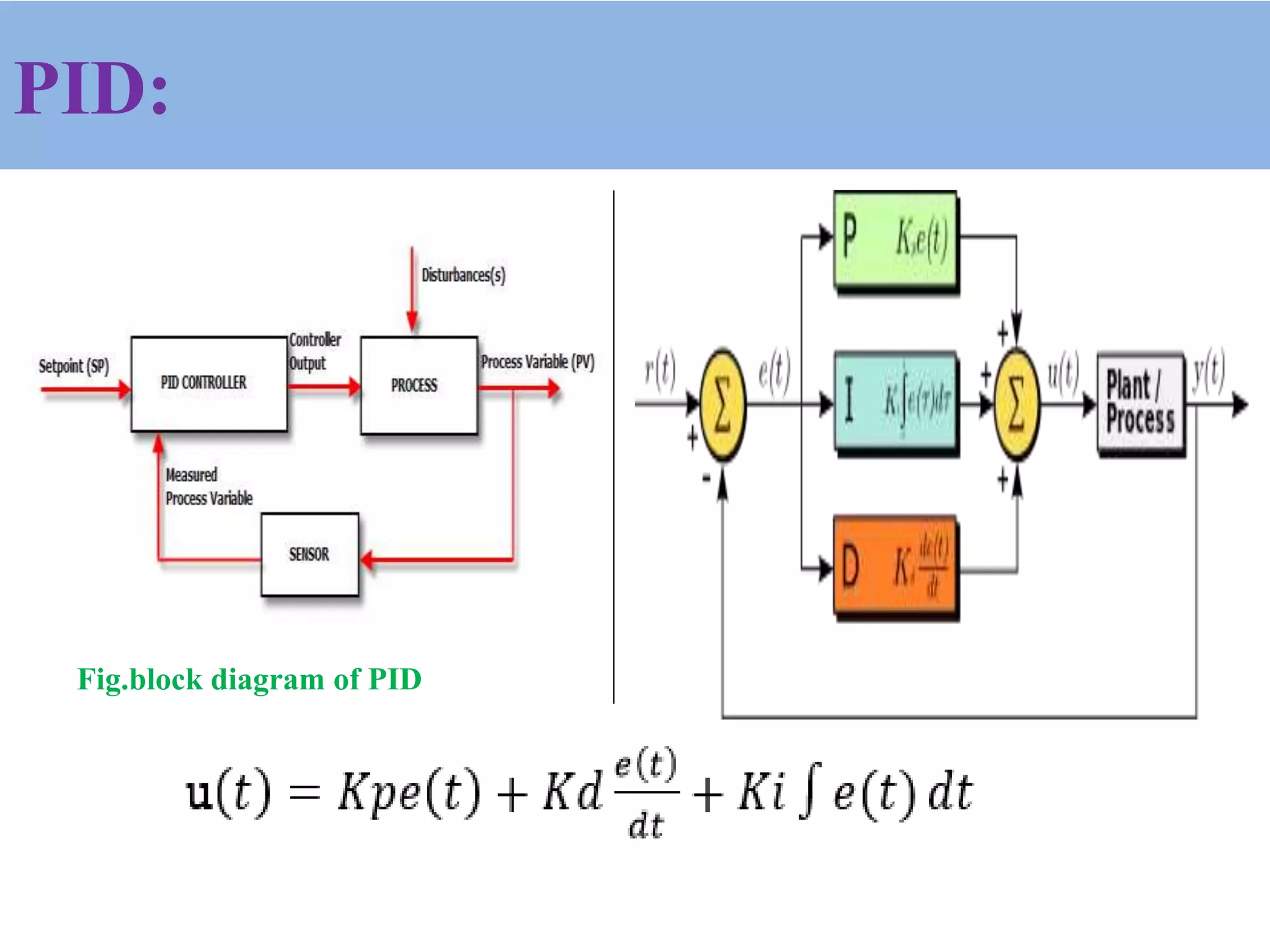

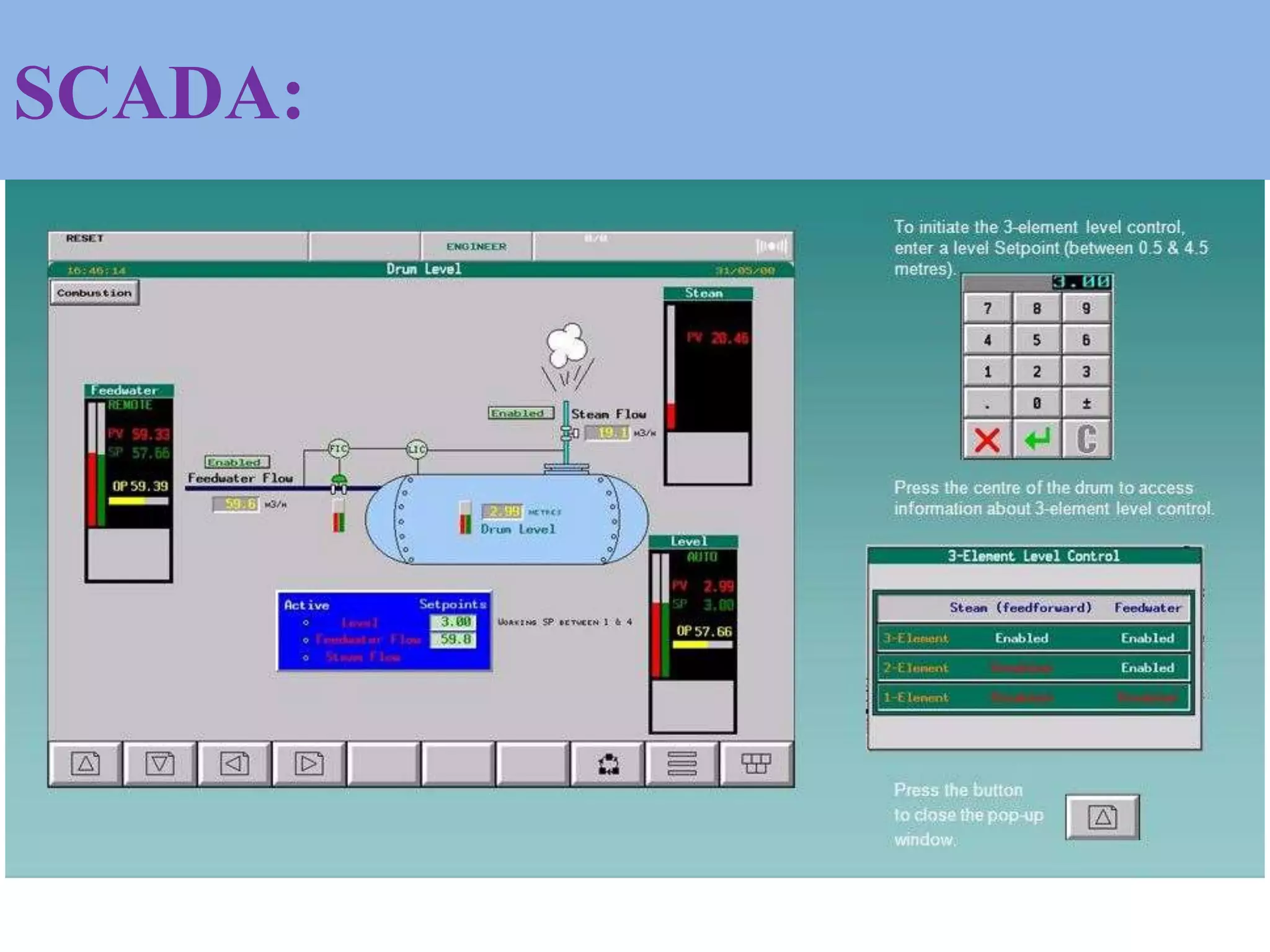

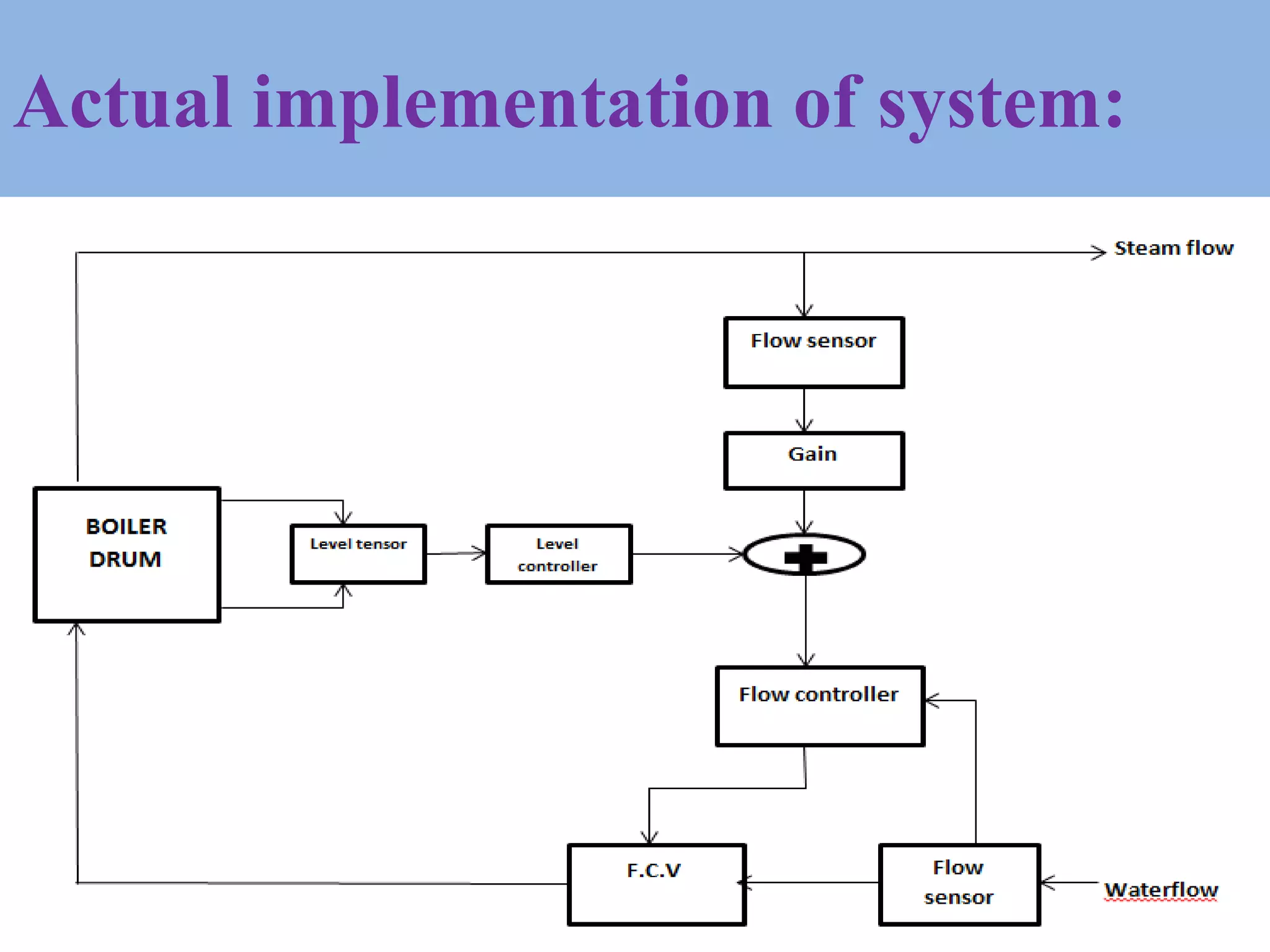

This document presents a project on 3 element control of a boiler system using a programmable logic controller (PLC), proportional-integral-derivative (PID) controller, and supervisory control and data acquisition (SCADA) interface. The proposed system aims to overcome limitations of previous control systems by automating control of parameters like temperature, pressure, and water level using various sensors connected to a PLC. The PLC is configured to control actuators based on input from sensors and PID logic. A SCADA interface is used to monitor parameters. Experimental results showed the system could effectively control water level and pressure based on defined setpoints and alarm thresholds.

![Presented By,

Mr.Godase V. V. [M.E .II.]

(DEPARTMENT OF ELECTRONICS ENGINEERING)

Under the guidance of,

Mr.Jagadale A.B

3 ELEMENT CONTROL USING PLC-

PID & SCADA INTERFACE](https://image.slidesharecdn.com/m-220216081839/75/M-e-paper-ppt-new-1-1-2048.jpg)

![DRUM LEVEL CONTROL:

1]SINGLE ELEMENT CONTROL

2]TWO ELEMENT CONTROL

3]THREE ELEMENT CONTROL](https://image.slidesharecdn.com/m-220216081839/75/M-e-paper-ppt-new-1-5-2048.jpg)

![REFERANCES:

• 1] Roopal Agrawal, Umesh C. Pati, ―Design and Data Logging of Three Element Boiler Level Control

Using LabVIEW‖, National Conference on Recent Advances in Chemical and Environmental

Engineering (RACEE), Rourkela, Jan 2018

• [2]Electricaltechnologywebsiteavailablehttps://www.electricaltechnology.org2015/09/what-is-industrial-

automation.html

• [3] S.Kalaivani and M.Jagadeeswari PLC & SCADA Based Effective Boiler Automation System for

Thermal Power Plant International Journal of Advanced Research in Computer Engineering &

Technology (IJARCET) Volume 4 Issue 4, April 2015

• [4] Patel Pratikbhai, 2Rokade Shashikant, 3 Gilbile Sameer, 4S.S.Shingare Design and development of 3

element control of boiler Vol-2 Issue-3 2016

• [5] 1Keyur Solanki, 2Jalpa Shah, 3Nishith Bhatt –‘Modeling and Simulation of prototype of boiler drum

level control’ ISSN (Print) : 2321-5747, Volume-2, Issue-2,2014

• [6] Lakshmi P M1, Dr.H.Prasanna Kumar2’’ One/Three Element Method using PLC DCS” International

Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering Vol. 5, Issue 8,

August 2016

• [7]1Mr. J.Gnana Arun Johnson, 2Neethu P S, ‘FUZZY LOGIC BOILER DRUM LEVEL CONTROL’

International Journal of Pure and Applied Mathematics Volume 116 No. 23 2017, 463-469

• [8] V. Pavithra, Dr. G. Mary Jansi Rani ‘Boiler Drum Level Control Using Internal Model Controller’©

2015 IJIRT | Volume 1 Issue 12 | ISSN: 2349-6002

• [9] Sayyad Rifat Arbaaz 1, Prof. W.V.Patil2 & Mr. Sunil Panchal3“Development of Advanced Boiler

Automation for Sugar Industries” Imperial Journal of Interdisciplinary Research (IJIR) Vol-3,Issue 2017](https://image.slidesharecdn.com/m-220216081839/75/M-e-paper-ppt-new-1-24-2048.jpg)