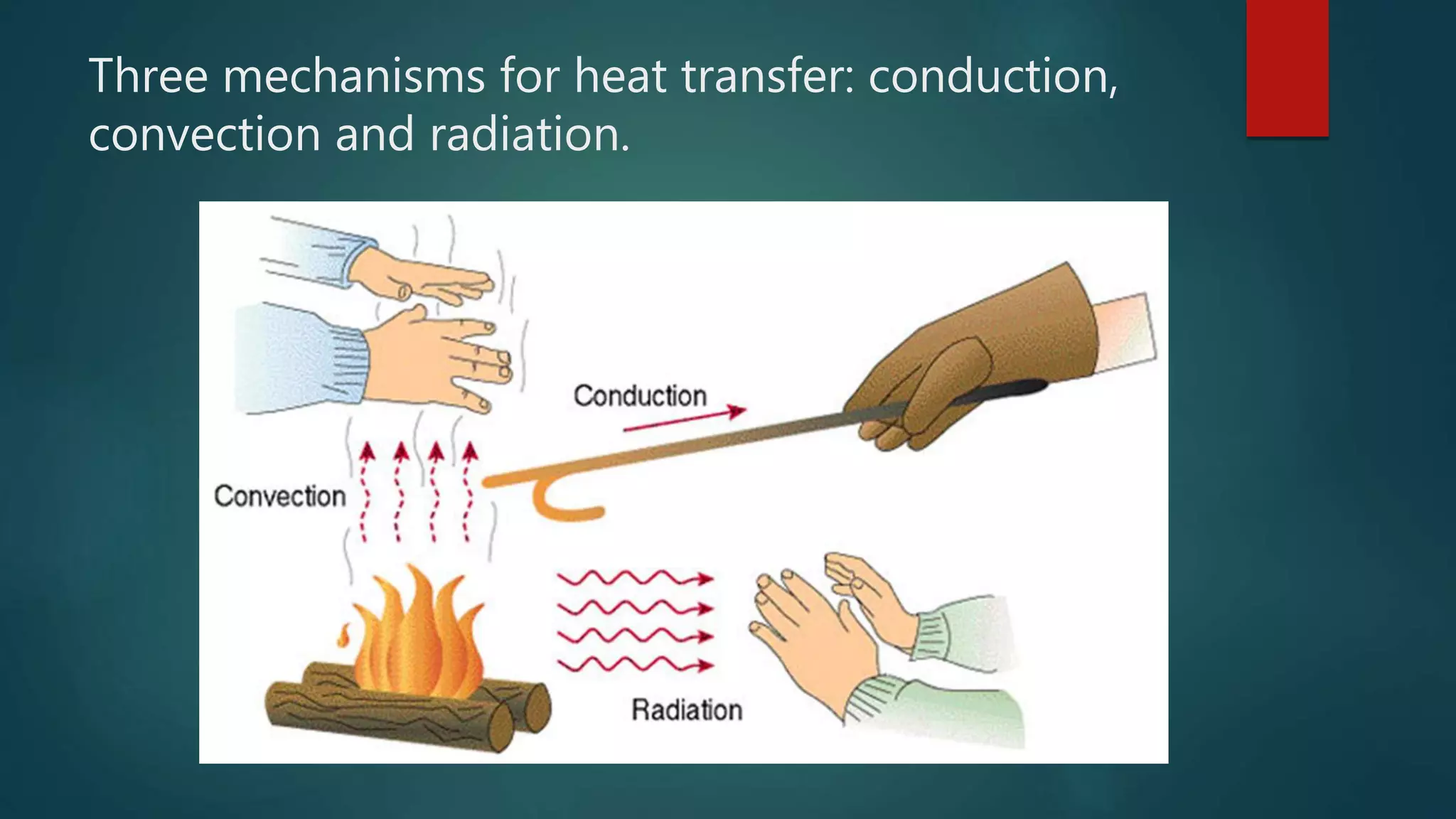

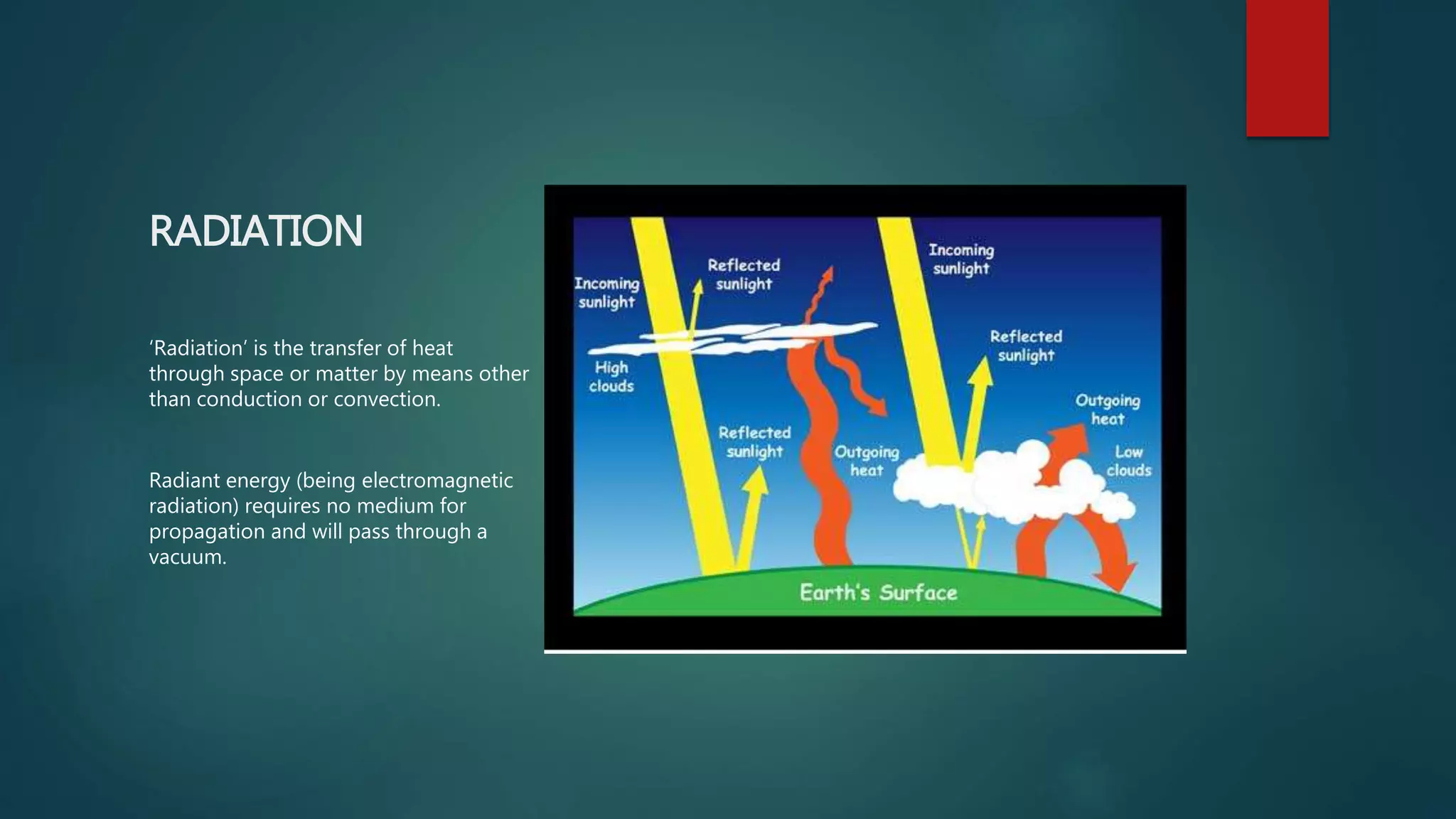

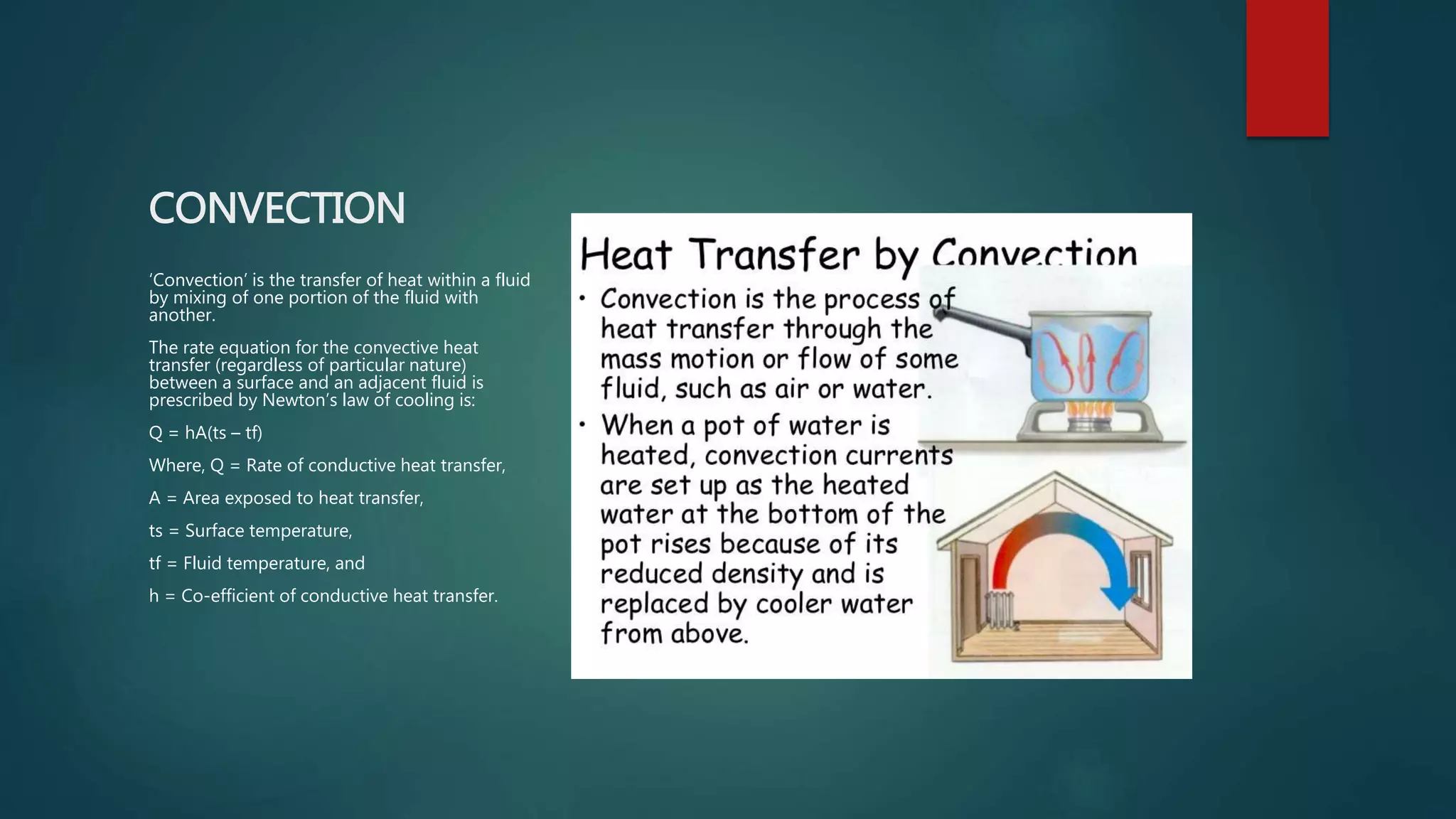

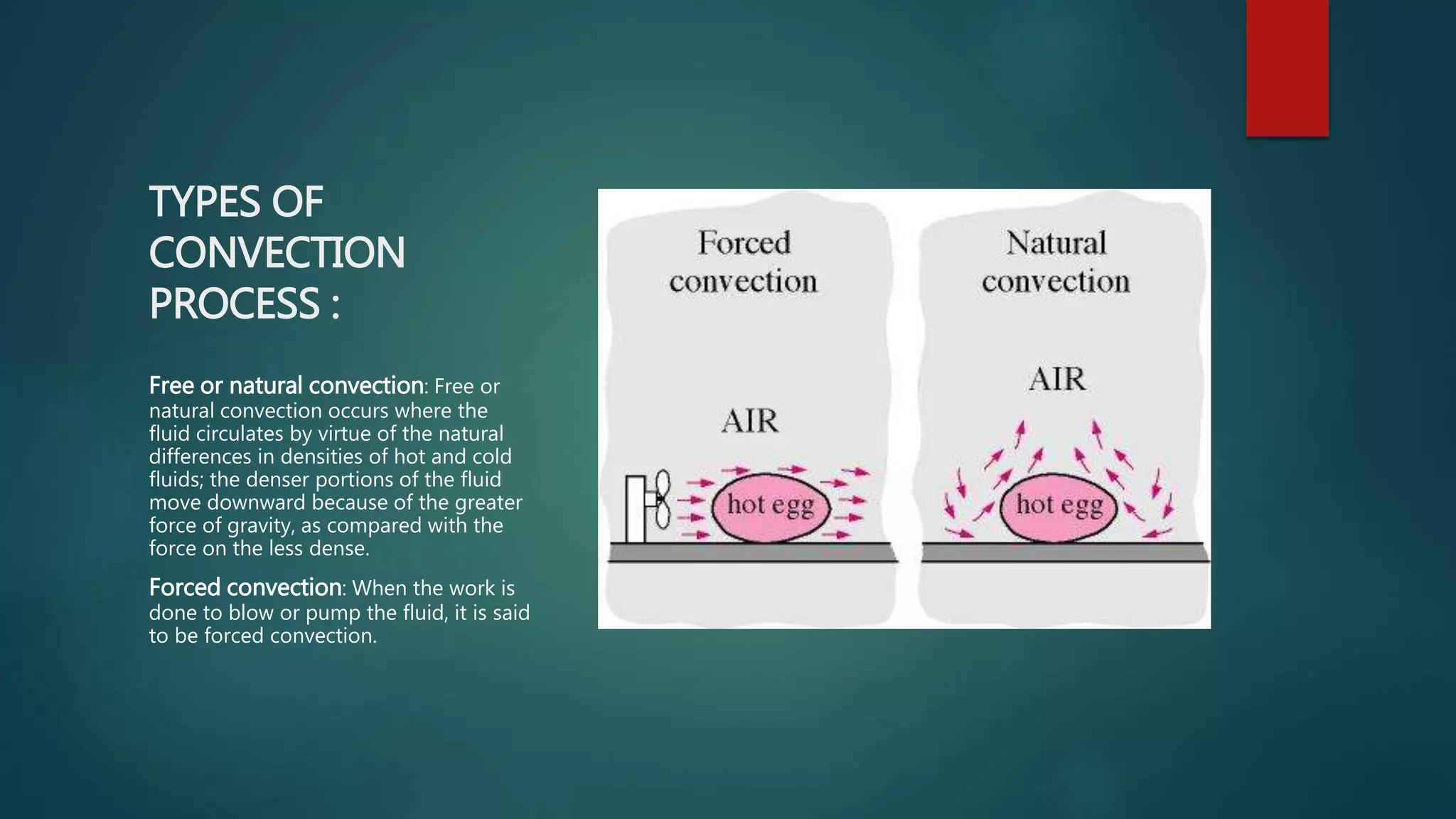

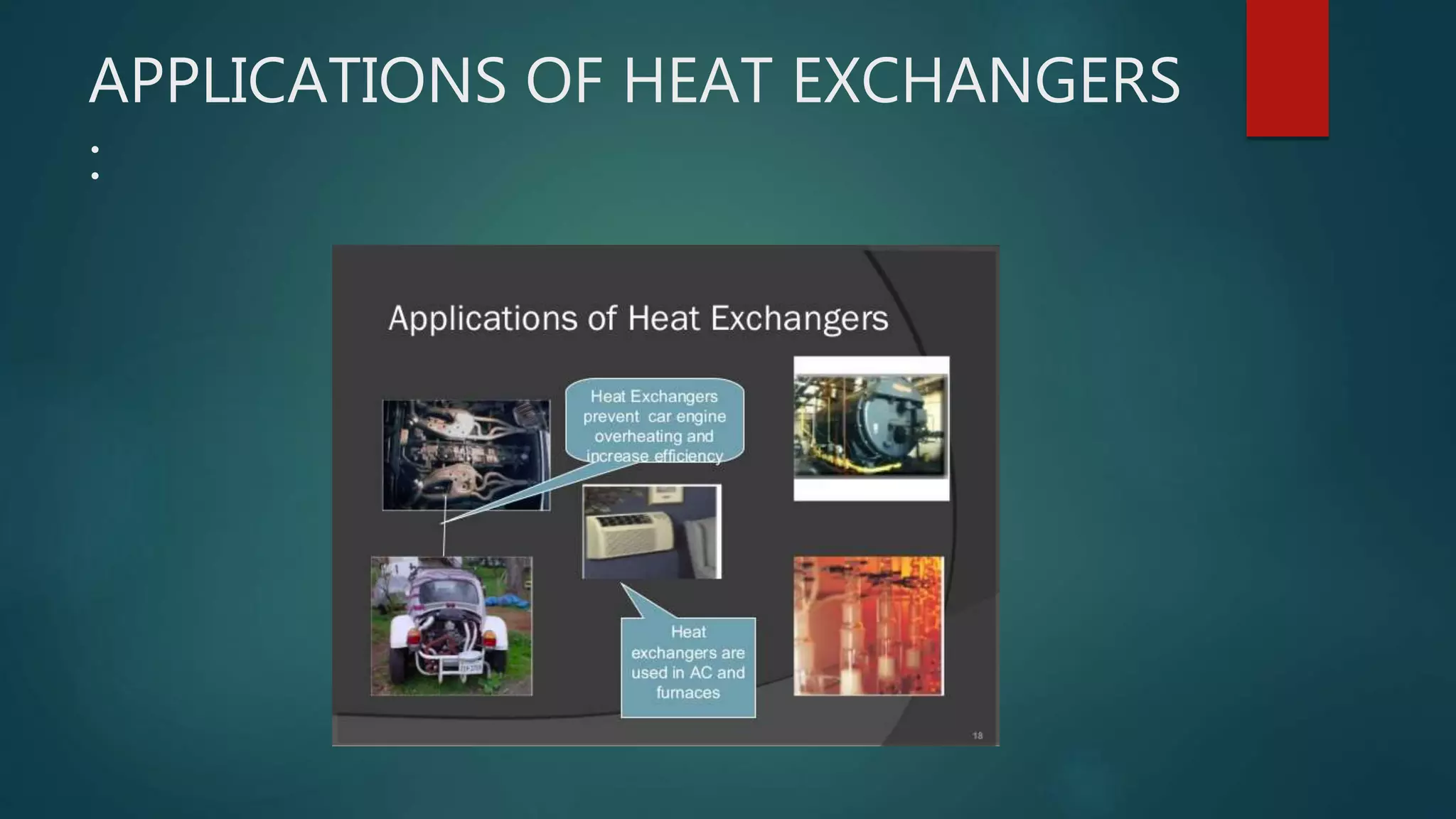

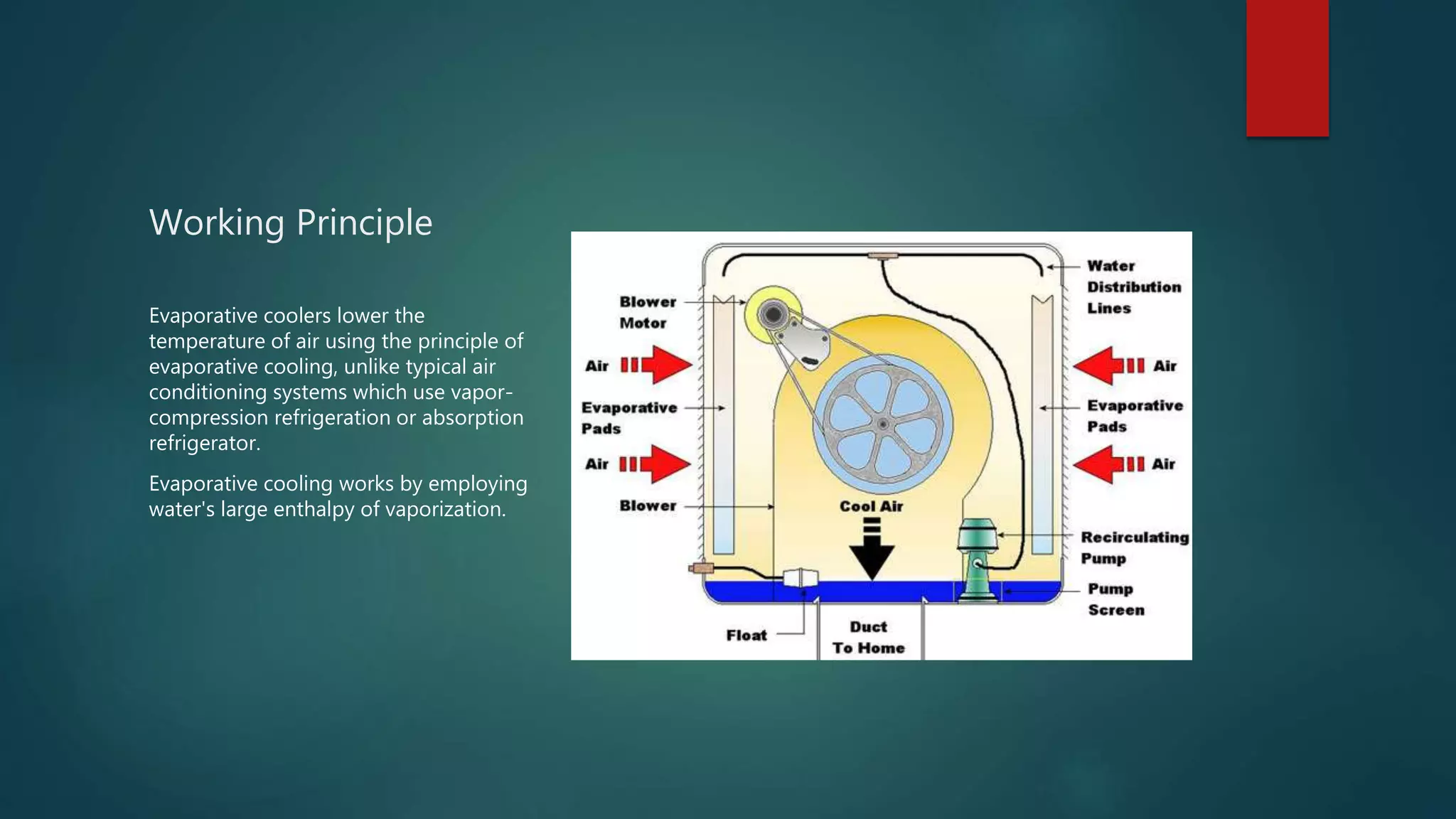

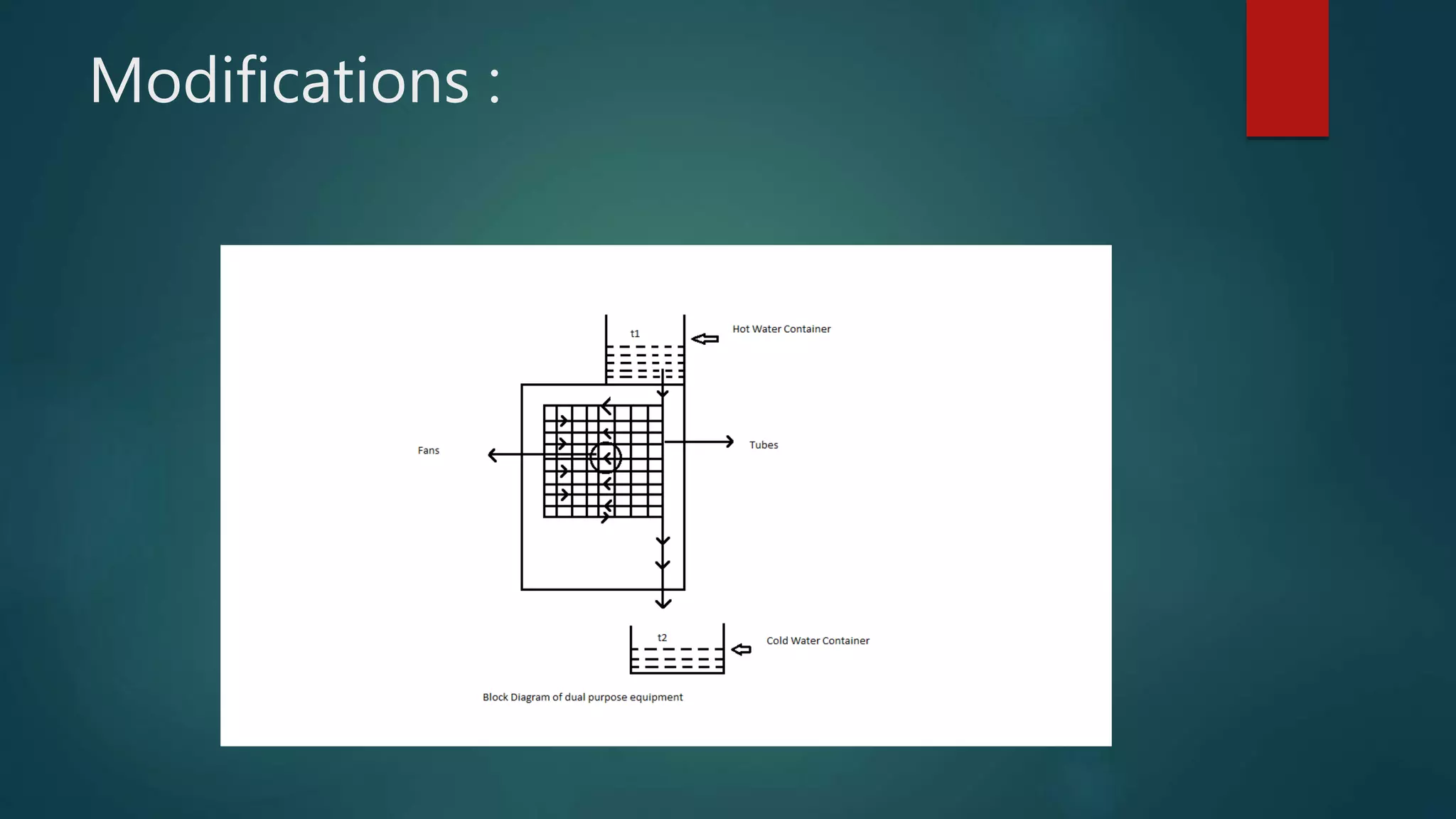

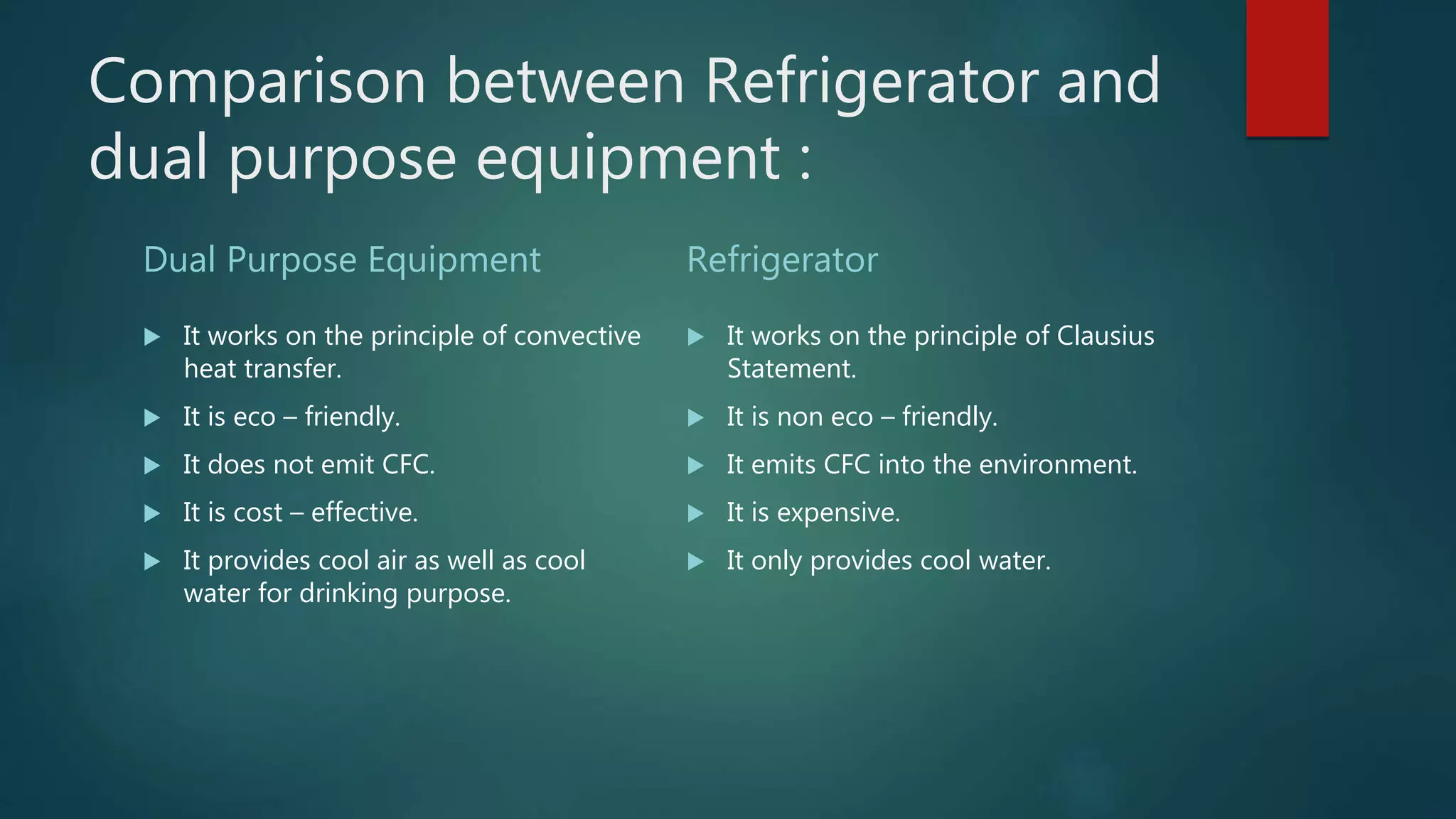

This document describes a student project to build a device that cools water through convection. It discusses the basic principles of heat transfer through conduction, convection and radiation. It focuses on convection, describing natural and forced convection. The device would use a heat exchanger design with tubes that allow hot water to lose heat to cold air flowing over the tubes. Calculations are provided to determine the heat lost and temperature change of the water. The device aims to provide both cooled drinking water and air, making it a low-cost alternative to a refrigerator.