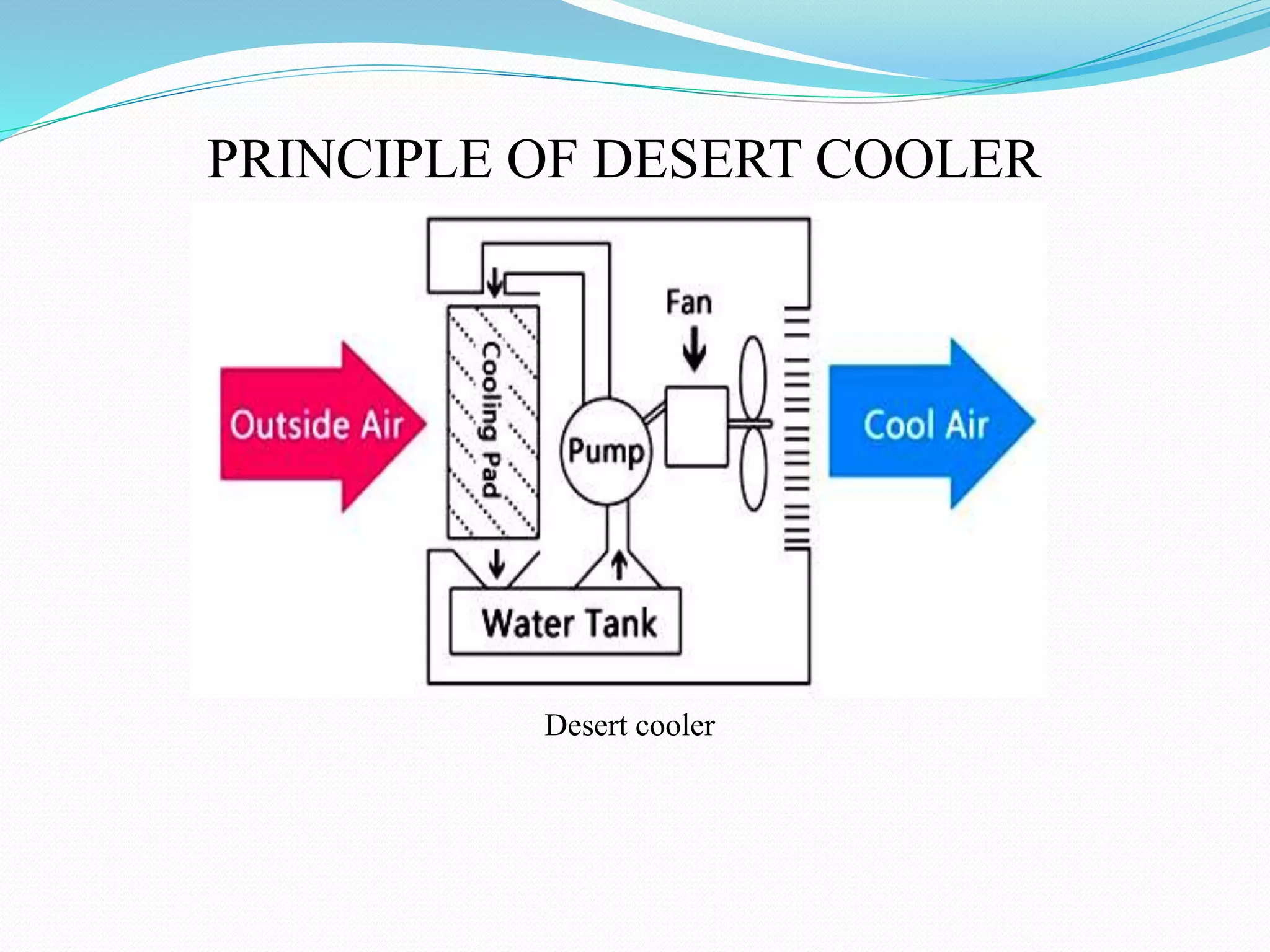

This document describes the design and analysis of a hybrid cooler. It discusses the principles of evaporative cooling and how desert coolers work by blowing dry, hot air over a wet surface, which cools the air through evaporation. The methodology section outlines the development of a mathematical model, fabrication of the proposed design, experimental validation, and measurement of coefficient of performance. The expected outcomes are a new hybrid cooler design that provides both air conditioning and water cooling using evaporation, serving as an environmentally friendly alternative to air conditioners. Key components of the design include cooling pads, fans, pumps, and stainless steel sheets. References are provided on previous research conducted on evaporative cooling and desert cooler performance.

![REFRENCES

[1] J.R. Watt., Evaporative Air conditioning hand book, 2nd Edn. Chapman and

Hall, New York , (1986).

[2] M.L Mathur, B.P Jain., Performance of a portable cooler; Desert cooler.,

J.Inst. Engr. India 59,241-245, (1979).

[3] M.L Mathur, B.P Jain., Experimental study of performance of portable air

washer type Air cooler, Journal of Institute of Engineers India 63, 38-40,

(1982).

[4] R.L Sawhney, S.P Singh, N.K Bansal, M.S Sodha., Optimization of an

evaporative cooler for space cooling., Int. J. Housing Sc. and its Applns.11,

225-231, (1987).

[5] S.P Singh, R.L Sawhney, N.K Bansal, M.S Sodha., Sizing of an

evaporative cooler for thermal comfort inside a room, Int. J. Housing Sc.

and its Applns.11, 141-148, (1987).](https://image.slidesharecdn.com/newmicrosoftofficepowerpointpresentation-170206110428/75/New-microsoft-office-power-point-presentation-14-2048.jpg)

![[6] M.S Sodha, J. Kaur, R.L Sawhney,R. Kamal., Thermal performance of a

building coupled to an evaporative cooling tower; Parametric studies., Int.J.

Energy Research15, 1-10. (1991a).

[7] B. Ringavkuli, S. Kumar., An experimental study of a novel dew point

evaporative cooling system, Energy and Buildings 42 (5), 637-644, (2010).

[8] J.A Dowdy,N.S Karabash., Experimental determination of heat and mass

transfer coefficients in rigid impregnated cellulose evaporative media, ASHRAE

Trans. 93 Part 2 , 382-395, (1987).

[9] J.R Camargo,J.R Ebinuma,C.D., A mathematical model for direct and

indirect evaporative cooling air conditioning systems, Proceedings of the 9th

Brazilian Congress of Thermal Engineering and Sciences (2002).

[10] J.M Wu, Huang, H Zhang, Theoretical analysis on heat and mass

transfer in a direct evaporative cooler, Applied Thermal Engineering 29, 980-

984, (2009a).](https://image.slidesharecdn.com/newmicrosoftofficepowerpointpresentation-170206110428/75/New-microsoft-office-power-point-presentation-15-2048.jpg)

![[11] J.M Wu, Huang,H Zhang., Numerical investigation on the heat and

mass transfer in a direct evaporative cooler, Applied Thermal

Engineering 29, 195-201,( 2009b).

[12] M.S Sodha, S.P Singh,S.P, R.L Sawhney., Evolution of design

pattern for direct evaporative coolers, Building and Environment 30 ,

287-291, (1985)

[13] P.J.Erens andA.A.Dreyer.,.Modelling of indirect evaporative air

coolers., International Journal of Heat and Mass Transfer 36, (1993)

[14] T.R.Tulsidasani, R.L.Sawhney, S.P. Singh and M.S.Sodha., Recent

Researches on an indirect Evaporative Cooler-I: Optimization of COP

of an indirect Evaporative Cooler (IEC)., International Journal of

Energy Research, 21, 1099-1108, (1997).

[15] Dr. Aneesh Somwanshi., Recent Researches in Performance of

Direct Evaporative Cooler ( Desert cooler) for Climate of Raipur

(Chhattisgarh).](https://image.slidesharecdn.com/newmicrosoftofficepowerpointpresentation-170206110428/75/New-microsoft-office-power-point-presentation-16-2048.jpg)