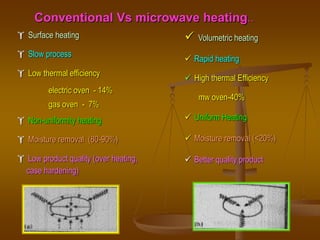

The document discusses microwave food processing technology. It notes that agricultural production in India was 209 million tons in 2001-2002 and that the agro-food processing sector accounts for 5% of India's GDP. It then discusses some advantages of microwave processing like uniform heating, higher efficiency, and better retention of nutrients compared to conventional heating. Finally, it provides some examples of microwave applications like tempering, cooking, drying, pasteurization and sterilization of various foods.

![Facts and statistics..

Agricultural production during 2001-02 was 209MT.

Agro and food processing sector ranks fifth in India’s GDP.

Employs around 18% of country’s industrial force.

Export growth from 2,821cr (91-92) to 10,770cr (2000-01).

Largest live stock population in the world.

Second, fifth and sixth largest producer of fruit &vegetables, eggs, & fish

respectively in the world

[ The Hindu oct-12, 2002 ]](https://image.slidesharecdn.com/14421908-microwave-heating-230531013927-28f2fc75/85/14421908-Microwave-Heating-ppt-2-320.jpg)

![Weakness of Indian food sector..

High wastage levels leading to low processing levels.

High seasonability & perishability – low profit margin.

Lack of requisite packaging quality and presentability required for

marketing.

Lack of ready acceptance in international marketing.

Higher cost of processing

[ The Hindu oct-12,2002 ]](https://image.slidesharecdn.com/14421908-microwave-heating-230531013927-28f2fc75/85/14421908-Microwave-Heating-ppt-3-320.jpg)

![Sectional view of a typical magnetron..

Antenna

Electrons form a rotating patterns

Equivalent circuit of

one resonant cavity

[ http:www.dtx.net 1999]

Internal parts of magnetron](https://image.slidesharecdn.com/14421908-microwave-heating-230531013927-28f2fc75/85/14421908-Microwave-Heating-ppt-15-320.jpg)

![Microwave conveyor system..

FDU-

543VD

54kW

2450MHz

6kW x 9

units

Dimensions (approx): 5.5 x 0.41x 1.52 (meters)

Material of Construction: SS - 300 grade

Conveyor Belt:

Width (0.30m) link

polypropylene belt

Conveyor Opening: H x w (0.03 to 0.08 x 0.32 m)

Elevation of Belt: 1.02 m

Belt Speed: 0 to 50 ft./min

Shipping Weight: 1180 Kg.

Conveyor Drive:

0.75 HP motor driven

sprocket and chain

Controller Panel:

Solid state controls digital

read out, convent belt speed

forward and reverse stop

start, inverter voltage supply

to drive motor

Electrical Requirements:

230V single/ three phase

50- 60 Hz Ac

Microwave Heating Power: 12 kW at 2450 MHz

Safety Interlocks:

Heating chamber, and Panel

interlocks

Removable end Panels:

Entry and exit tunnels and

side covers removable for

cleaning

Capacity- 0.5kg/min

[www.microwavereasearch.com]](https://image.slidesharecdn.com/14421908-microwave-heating-230531013927-28f2fc75/85/14421908-Microwave-Heating-ppt-17-320.jpg)