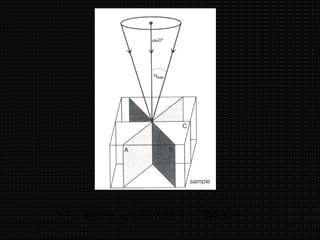

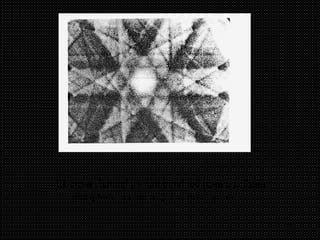

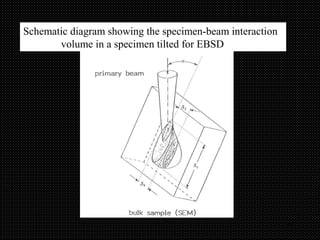

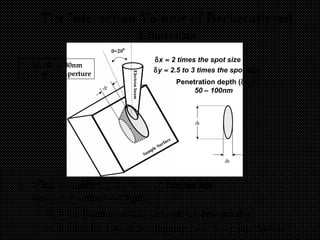

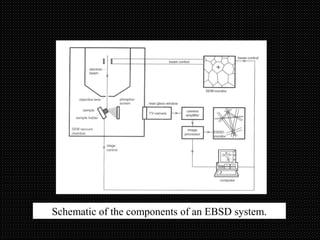

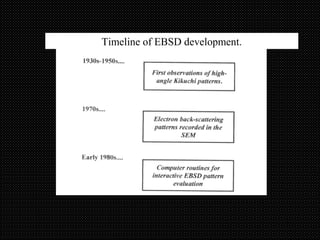

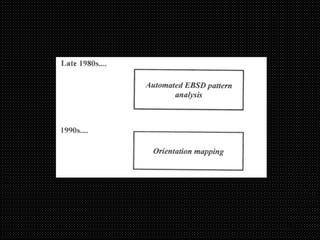

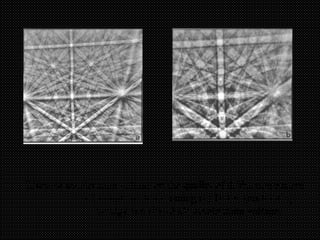

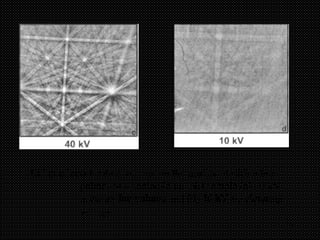

This document discusses several microtexture techniques for obtaining crystallographic information from samples, including Kossel technique, electron channeling pattern (ECP), and electron backscatter diffraction (EBSD). The Kossel technique uses X-rays to determine orientation, structure, and perfection. ECP forms diffraction patterns from tilting and rocking an electron beam. EBSD collects diffraction patterns from a tilted sample to determine orientation with high spatial resolution but a shallow interaction volume. Careful sample preparation is important to avoid surface damage for these techniques.