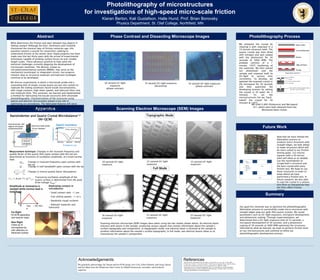

This document summarizes work done to develop a photolithography process for fabricating microscale structures on quartz crystals. The structures will be used to study friction at the microscale using a nanoindenter and quartz crystal microbalance. The process involves cleaning the crystals, spinning on photoresist, exposing the photoresist to UV light through a photomask, developing the structures, and hard baking them. The authors optimized the exposure time, development time, and photoresist coating parameters to produce structures with straight edges for future friction experiments exploring the effects of contact size, speed, material, and thin films.