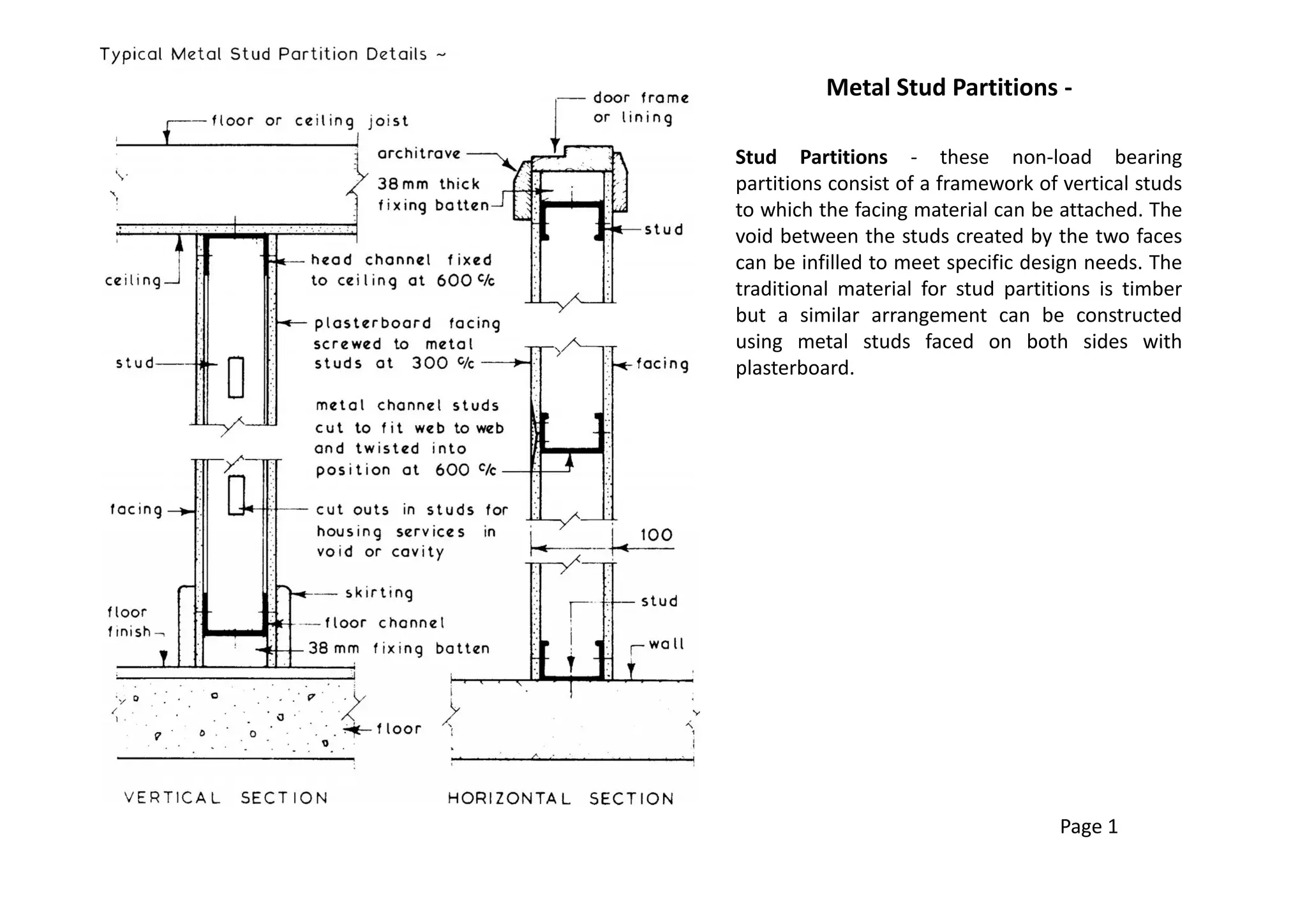

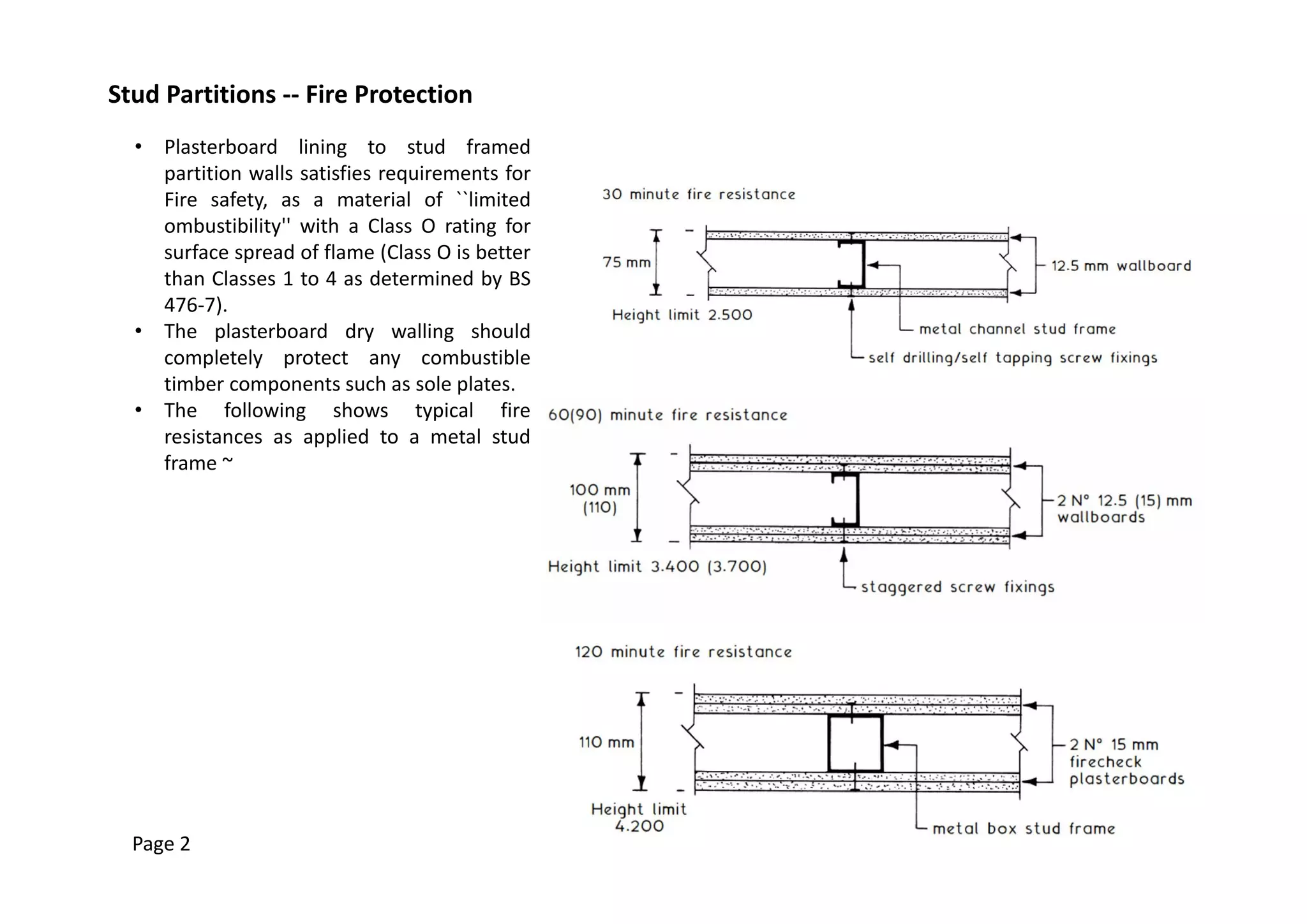

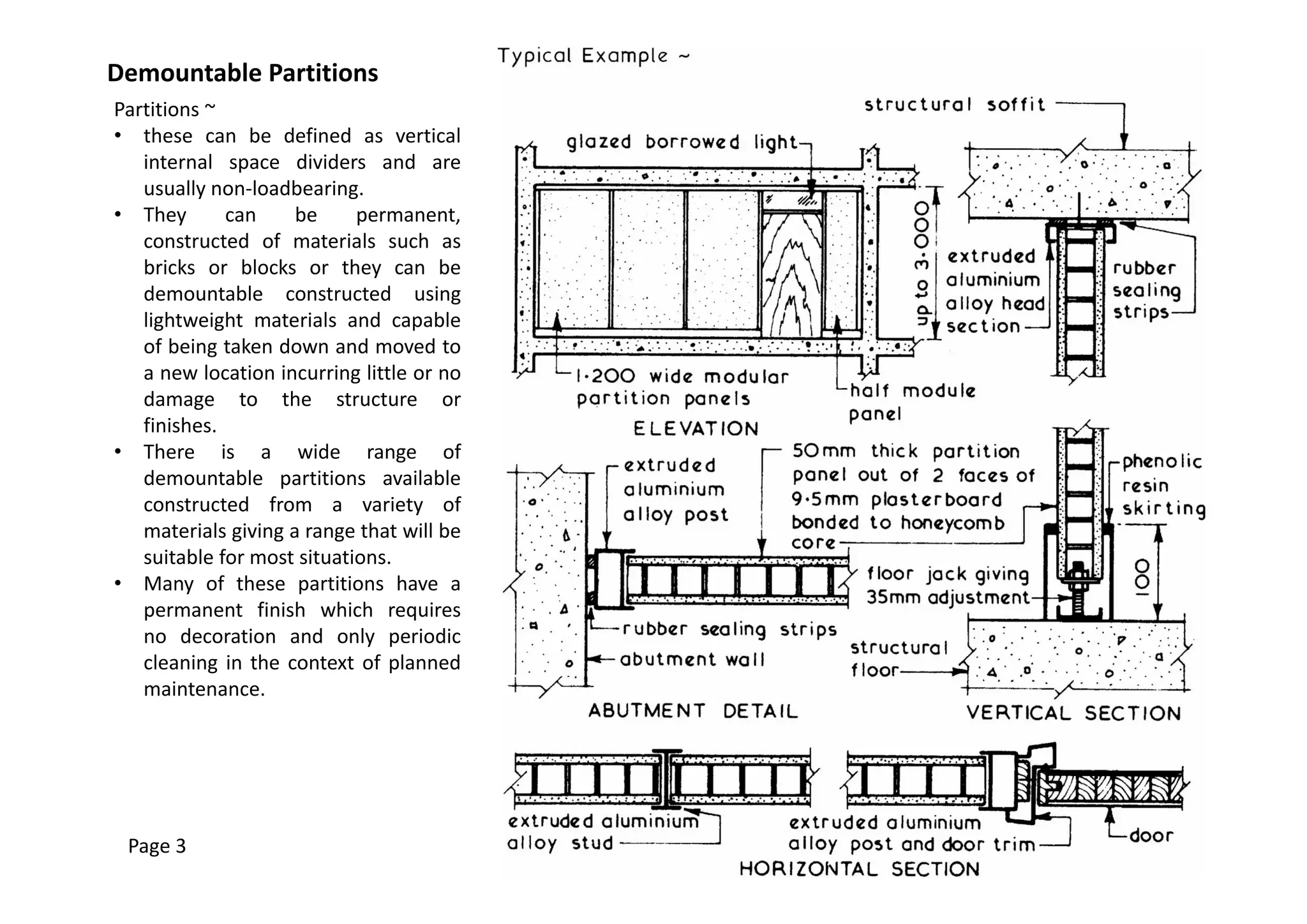

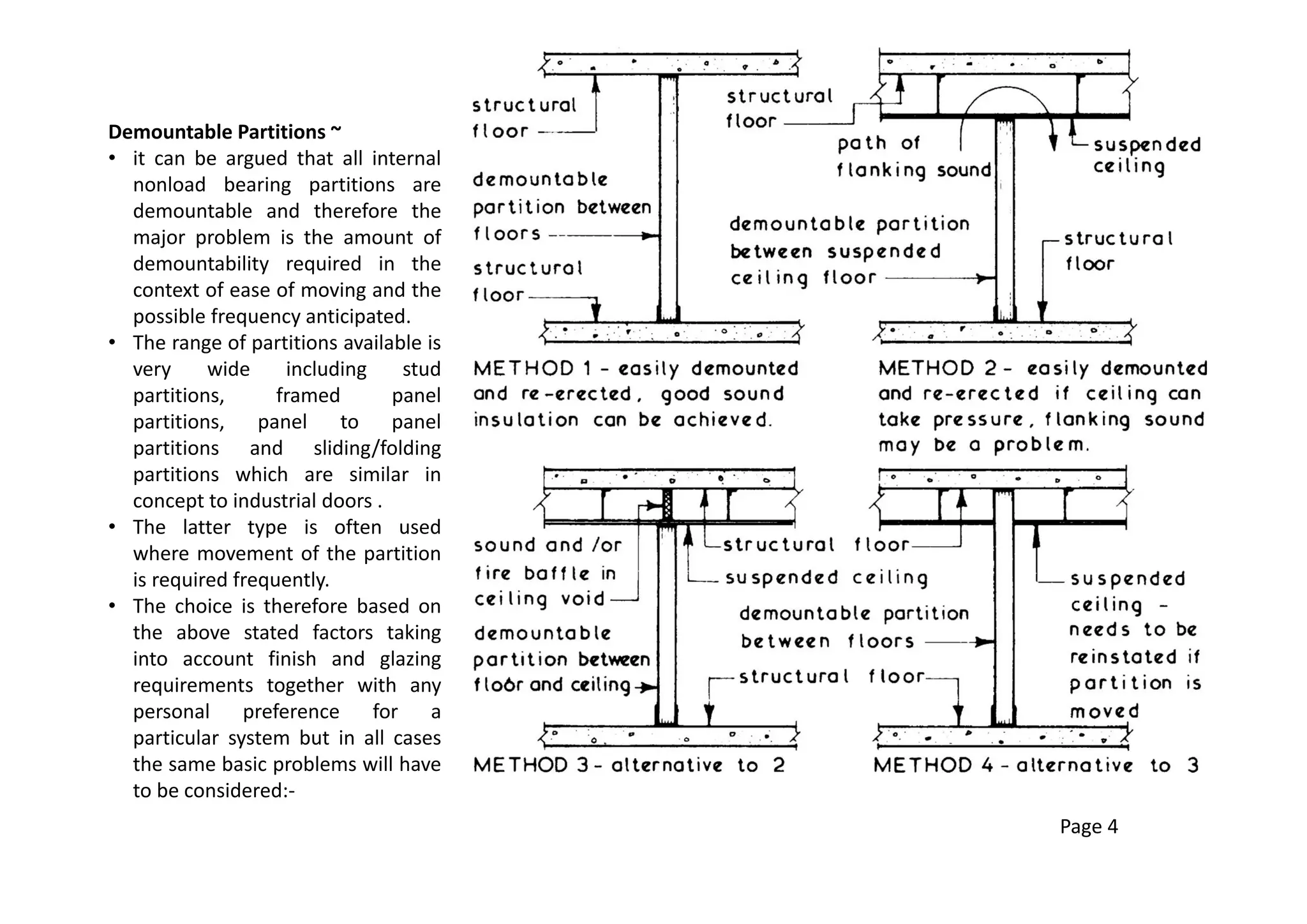

Metal stud partitions consist of a framework of vertical studs with a facing material attached. The space between the studs can be filled as needed. Traditionally timber was used but metal studs with plasterboard on both sides is also common. Plasterboard satisfies fire safety requirements as a material of limited combustibility with a Class O flame spread rating. Demountable partitions are internal dividers that are usually non-load bearing. They can be permanent or demountable to allow relocation with little damage. Demountable partitions come in many materials and styles, from stud partitions to framed panels to sliding/folding designs. Choice depends on finish, glazing, movement needs, and personal preference.